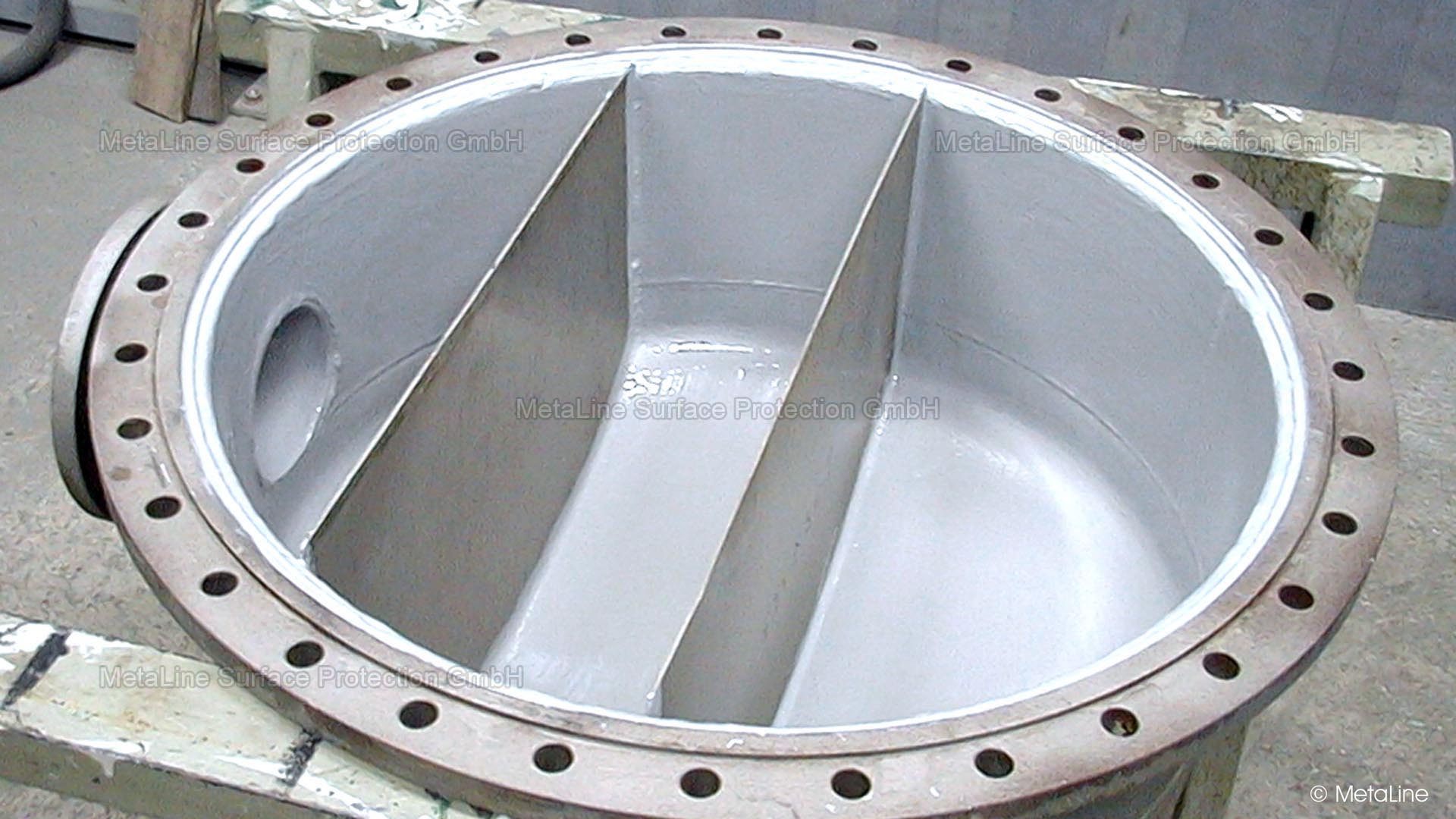

Dished end coating – all-over pinhole coating on a bigger casting component. MetaLine 100 XTM is a modern synthetic procedure to fight against leaking metal substrates

Chemical protection – a sealing barrier out of MetaLine 100 XTM protects and isolates metalic structures from chemical aggression

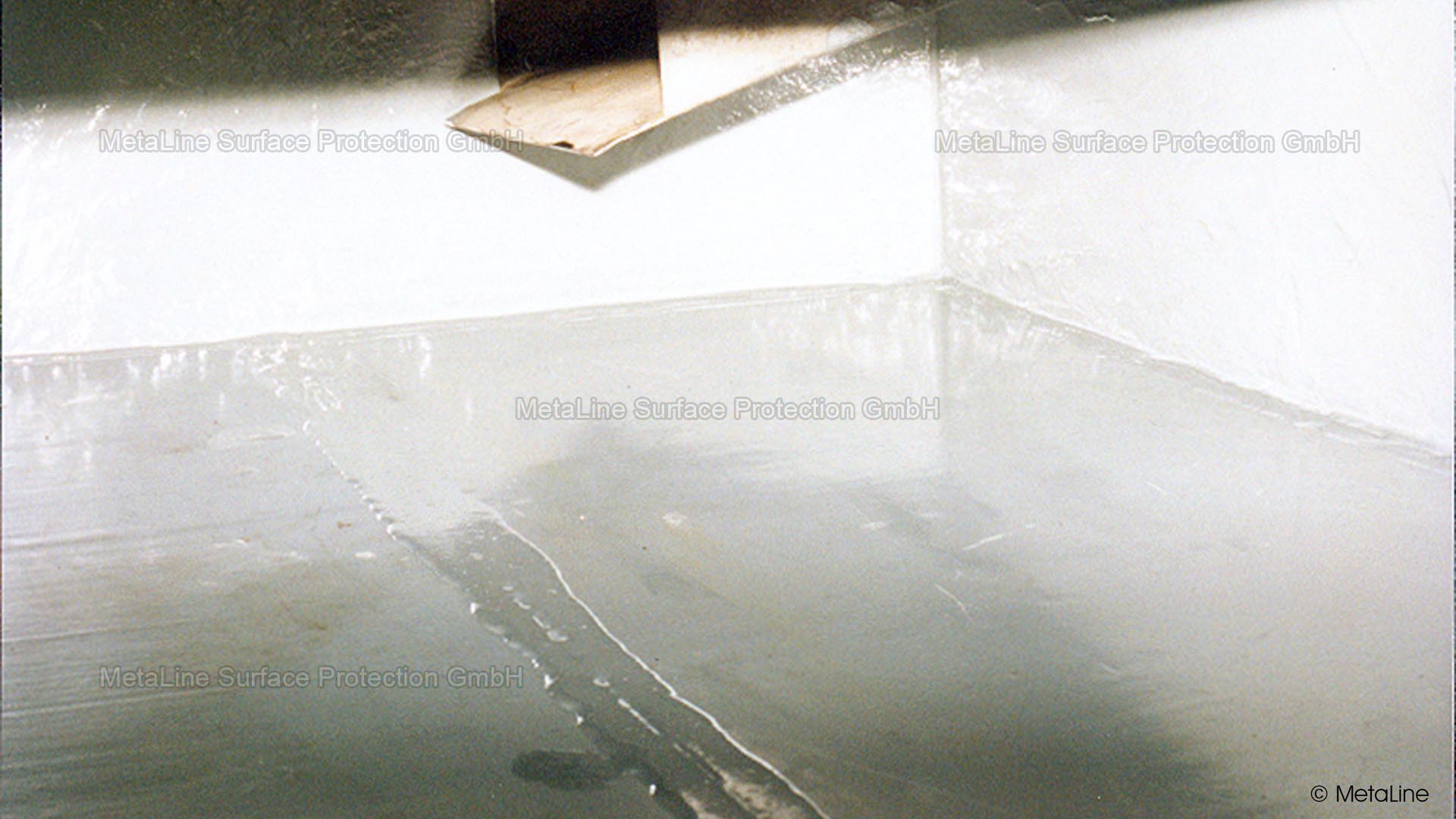

Washing plant coating - MetaLine 100 XTM is excellently suited for corrosion protection inside industrial washing plants

Industrial washer repair – Bi-metalic corrosion and pitting corrosion caused by brass chip introduction require an isolating coating system with excellent chemical resistance

Isolating coating system – even the most effective coating system requires a professional surface preparation. Here after preblasting. The remaining corrosion will be removed with the second blasting procedure

Corrosion protective coating – fully insulating and extremely chemical-resistant protective lining with MetaLine 100 XTM. As close as resistant as enamel

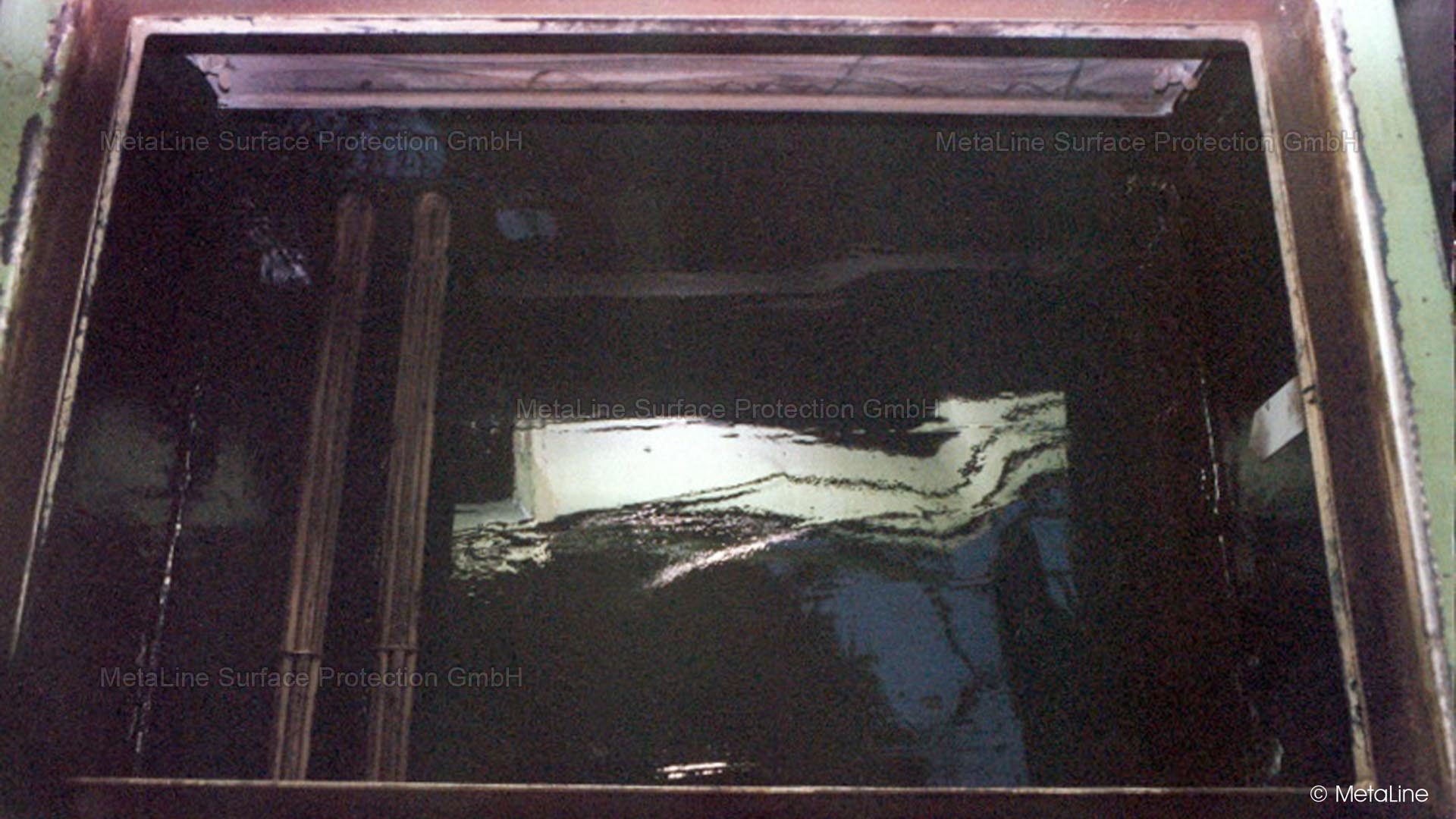

Welding seam overcoating – leaking hot washing plant (Pero) for aqueous serial cleaning of metal components. Bi-metalic corrosion caused by pollution leads to leakage problems. MetaLine has the solution

Welding seam sealing – the water basin was sealed, stabilized and isolated with several coats of MetaLine 100 XTM and new steel plates

Tank lining – owing to the metal/synthetic sandwich structure the expected life-time is higher compared to untreated new systems. Better than new is one of the philosophies of MetaLine . . .

Chemical protective coating - completely seamless, tight and prepared for higher temperature chemical attack. MetaLine 100 XTM protects even at elevated temperatures against liquid or gaseous aggression

Acid proof linings – high end equipment like this condenser require high end surface protective coatings. A case for MetaLine 100 XTM

Caustic resistant coating – chemical- and wear-resistant coating realized with MetaLine's 100 XTM technology

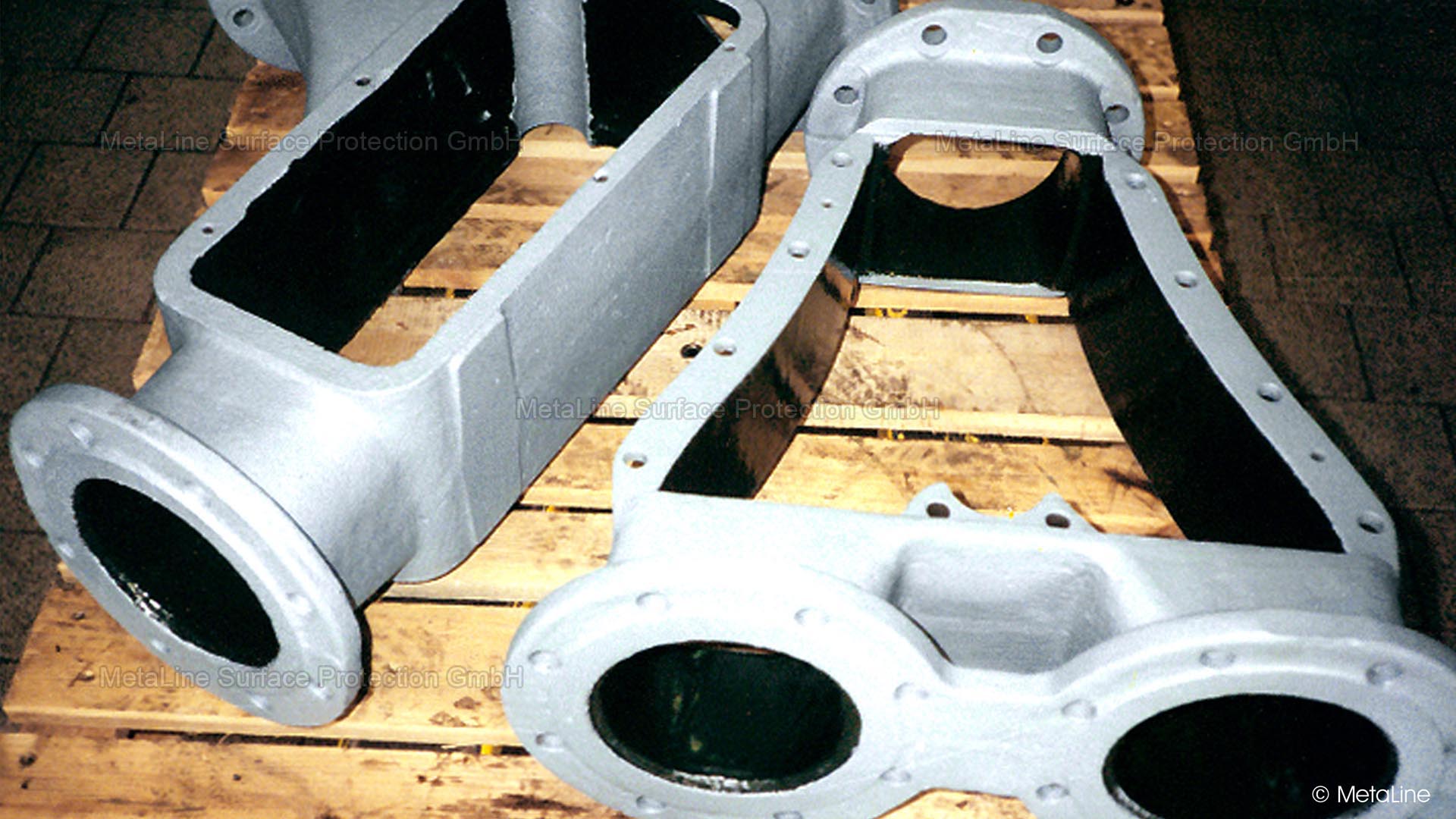

Chemical protective lining – a part from a French paper mill needed good chemical & wear resistance – a case for MetaLine 100 XTM

Chemical corrosion resistant coating – two coats of MetaLine 100 XTM had been brushed in by the customer – not the most beautifull application, but successfull

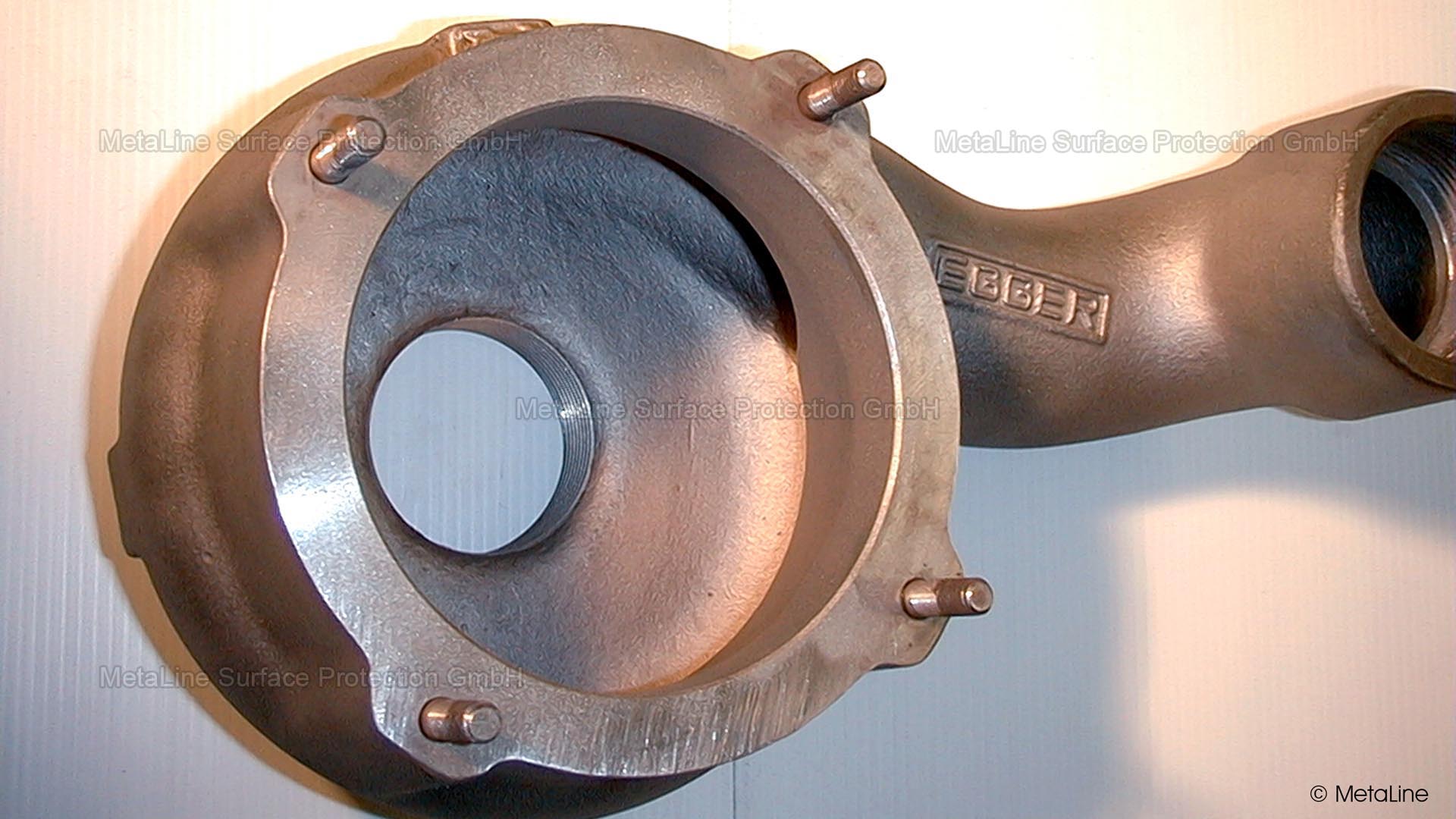

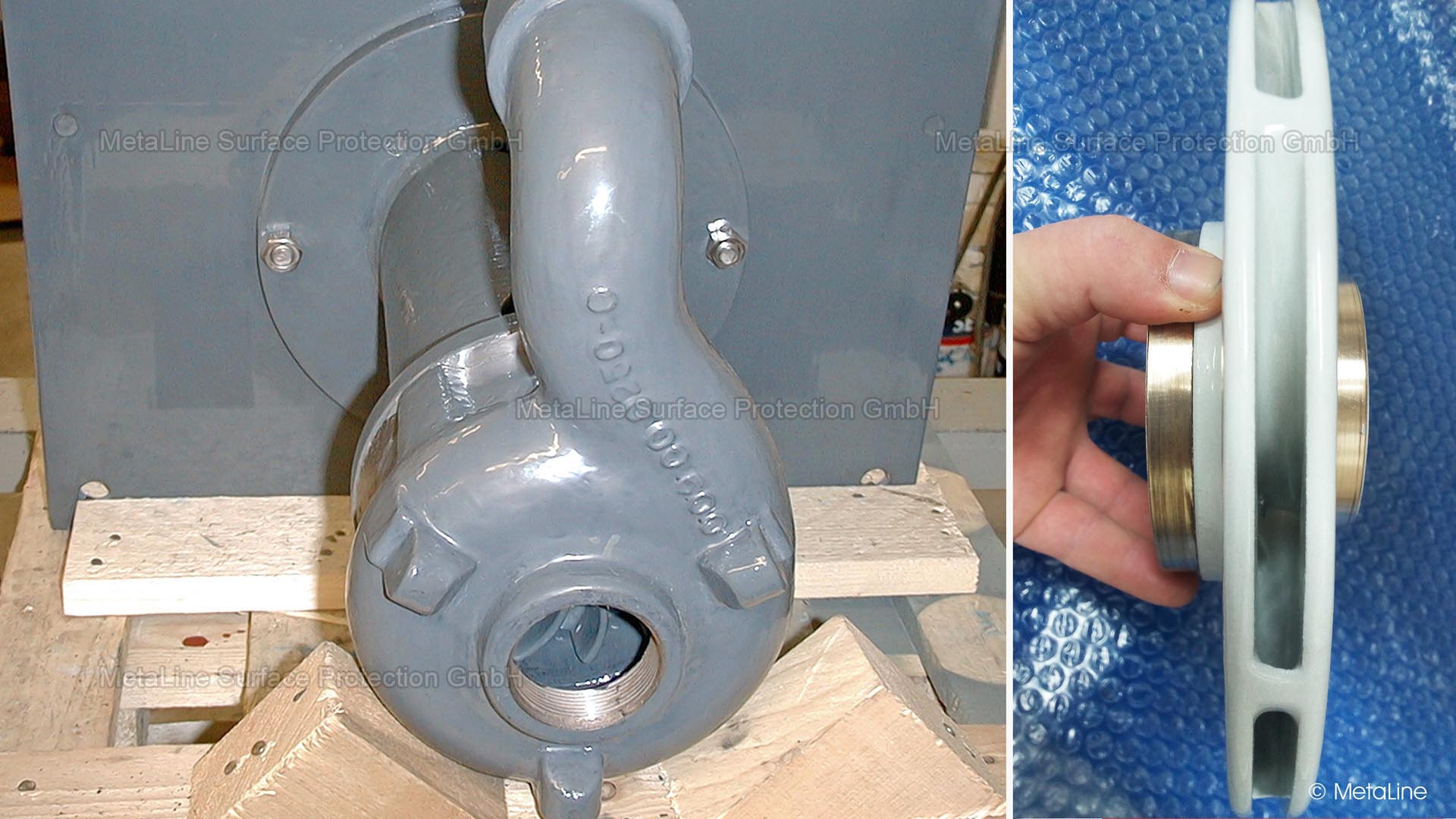

Lye resistant coating – an Egger-Pump needed inside & outside protection, primarely against chemical attack and corrosion

Acid resistant lining – MetaLine 100 XTM had been applied in two heavy coats by brush. Alternatively nowadays the MetaLine cartridge spray process could be used alternatively

Corrosion protective coating – a treatment with MetaLine 100 XTM protects this compressor casing from corrosion, abrasion and chemical attack

Chemical resistant treatment – coated, protected and preserved with MetaLine 100 XTM. One problem less for your daily maintenance duties

Lye resistant lining – a piece from the French chemical manufacturer Butachemie after the protection with three coats of MetaLine 100 XTM. Being protected in a pH range between 1-14

Chemical resistant coating system – a permanent protective treatment with MetaLine 100 XTM will cause a remarkable improve to all substrates in their overall resistance. Chemical protection as close as good as enamel

Manufacturing plant in a French paper factory confronted with moisture, chemicals and mechanical abrasion. Shown here after sandblasting immediately before application of MetaLine 100 XTM protective coating

Corrosion resistant coating – 2 coats of MetaLine 100 XTM provide a long term protection to this moisture impacted steel surface

Tank lining – a full coating with MetaLine 100XTM protects from chemical as well as biological corrosion and is relatively easy to install

Coating of a steel chimney - this approx. 30 meter (about 100 ft) high steel chimney was coated lying - inside - and then erected! Despite the bending moments during lifting, there were no cracks or chipping of the MetaLine 100XTM coating.

High performance coating - we hear very often in the requests that customers are looking for the "best on the market" - but it must be easy to process, with the simplest tools such as a brush. No, we can't fly to the moon in a paper rocket either . . .