Pump impeller coating – the largest pump impeller ever coated with MetaLine 785. 10 tons of steel being protected by our leading elastomeric spray technology

Turbine spiral casing coating - coated in Austria directly at the turbine manufacturer for a Chinese customer with 3 mm MetaLine 785.

Thruster coating - factory protective coating for an aluminium marine propulsion system to protect against erosion and cavitation at higher cruising speeds.

Screw wear protection with FDA approval - during coating of an auger conveyor with MetaLine 590 for low-wear transport of potatoes in starch production

Biomass feeding – MetaLine 785 protects the casing of this biomass feeder from wear and chemical corrosion. 5 mm coating thickness makes the difference . . .

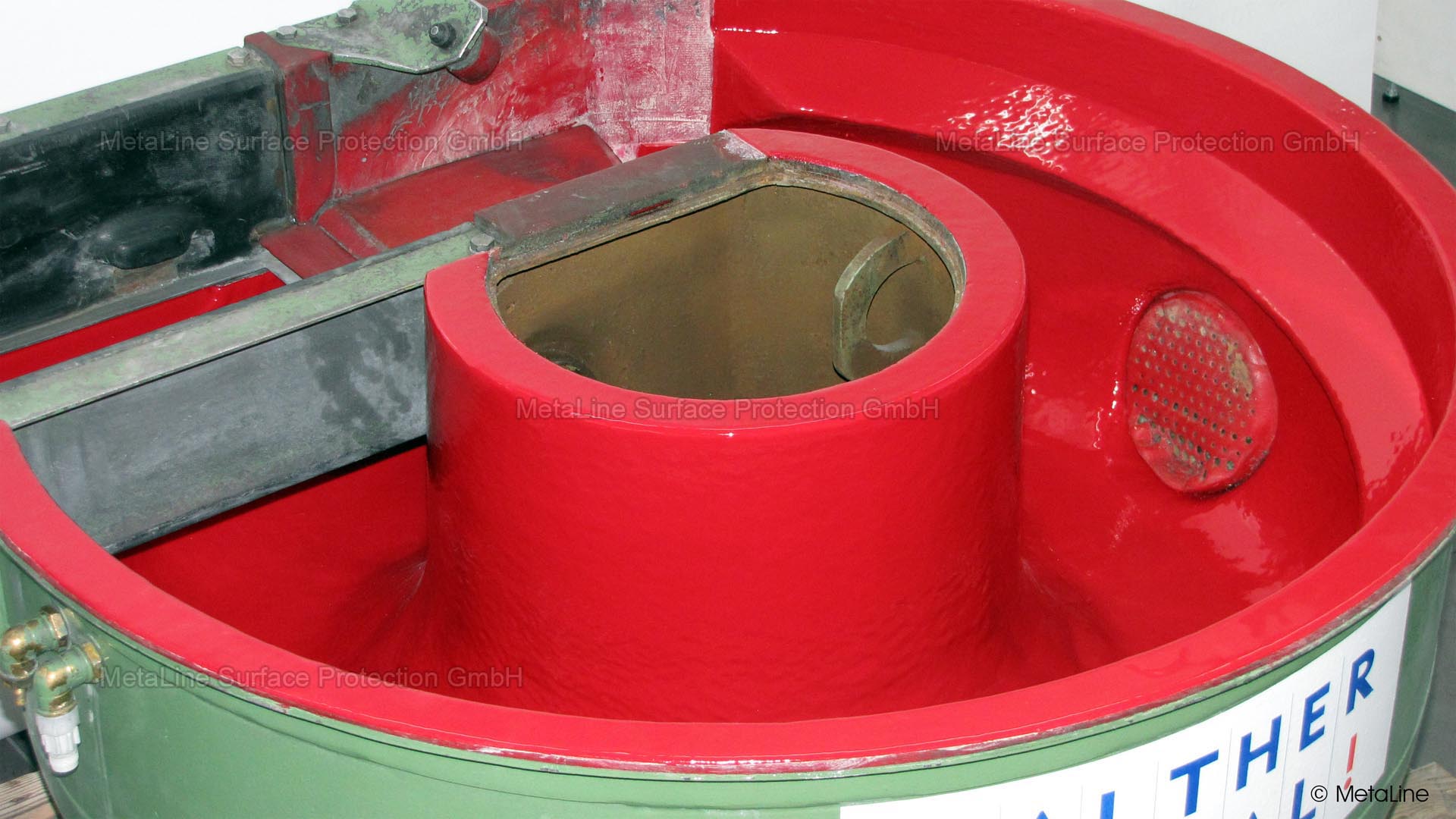

Tribofinishing coating – Repaired, overcoated and exactly as good as new equipment. However cheaper, more environmentaly safe and faster as the equipment manufacturer can offer repairservice to you

Chute coating - Inlet cone for concrete processing covered with 8 mm MetaLine 785. Wear resistant and non-stick . . .

Suction dredger coating - no matter which surface geometry has to be protected. Here the rubber pipes of a suction dredger. A case for MetaLine . . .

Valve lining - large valve coated and protected with MetaLine 785 directly at the Spanish manufacturer. Transport to a vulcanization plant was saved . . .

Fan coating - the low weight/density of MetaLine 785 is ideal for preventing imbalance and saving energy

Vacuum runner coating – the ultimate coating solution after a ceramical reconstruction is our sprayable elastomeric lining MetaLine 785. A new dimension in erosion and cavitation resistance

Pumpcoating – even special alloy casings of well known pump manufacturing brands can not resist the destroying forces in pulp & paper. MetaLine 785 is an elastomeric coating system greatly improving the resistance of pump casings

Impeller protection – 2 mm elastomeric coating with MetaLine 785 used on that closed impeller design

Wastewater pump coating - MetaLine 785 is at home on most cruise ships as an OEM protective coating for wastewater pumps . . .

Impeller improvement – an extremely smooth coating with 3 mm MetaLine 785 optimizes the surface characteristics and increases the grade of efficiency

Wear protection with MetaLine 785 - is there anything left to say here in terms of surface smoothness and thus improved effectiveness and the reduction of turbulence? NO - a brushed coating simply cannot do that . . .

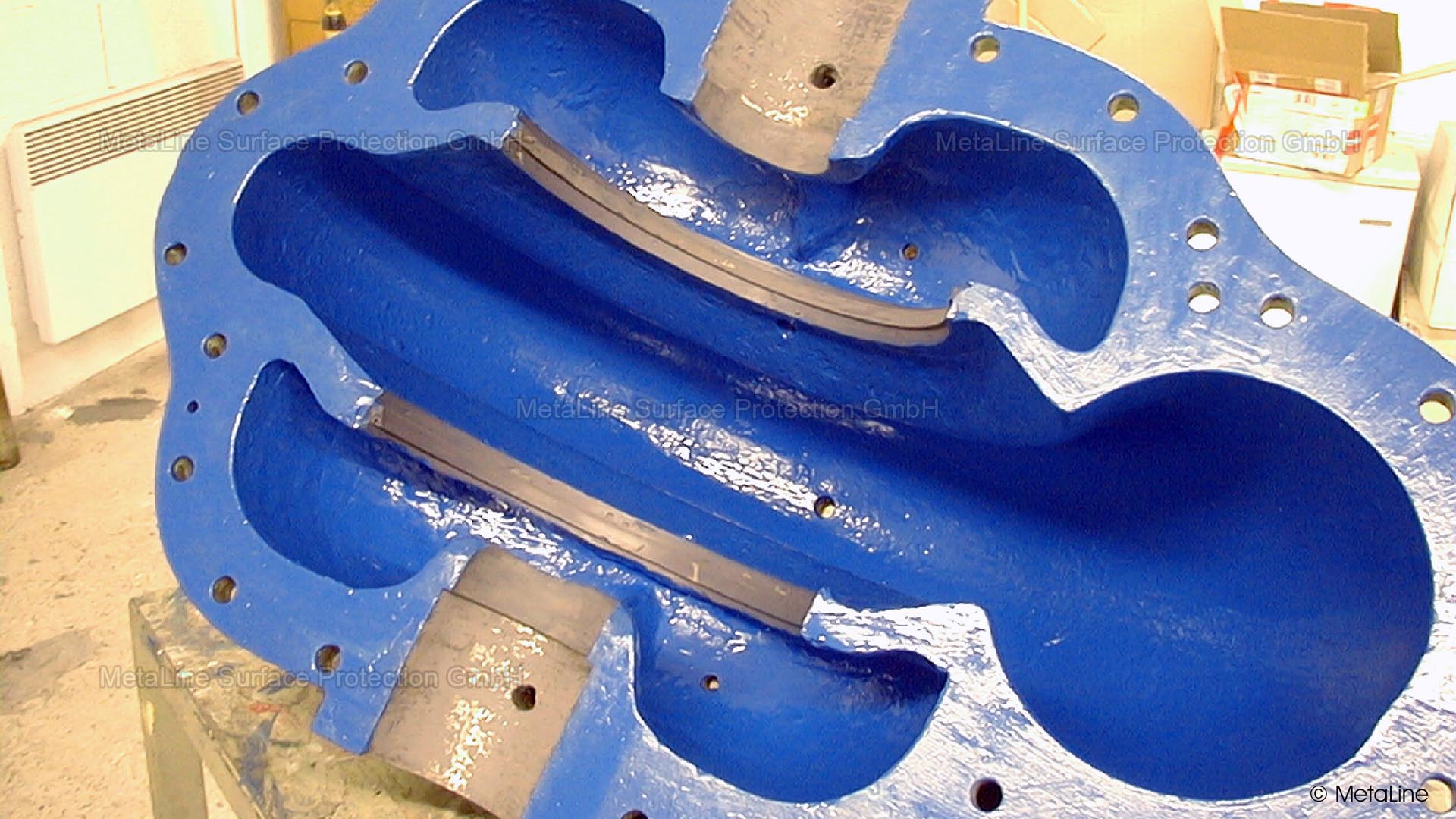

Spiral pump casings are amongst the most commonly known pump types – MetaLine offers professional protection concepts for these pumps

Flange gasket - it doesn't get any more fitting than this! Seamless wear protection in a 12 meter pipe and undercutting protection at the flange by means of MetaLine 785

Screw conveyor armoring - a protective coating with 8 mm MetaLine 785 in a drum-shaped screw conveyor

Mixer lining - this KSB pump conveys and chops in a sewage treatment plant. With a MetaLine 795 coating, it works better and lasts longer!

Impact wear protection with MetaLine 785 - 3 mm applied to the guide vanes with absolute contour accuracy on site in a Nepalese hydropower plant.

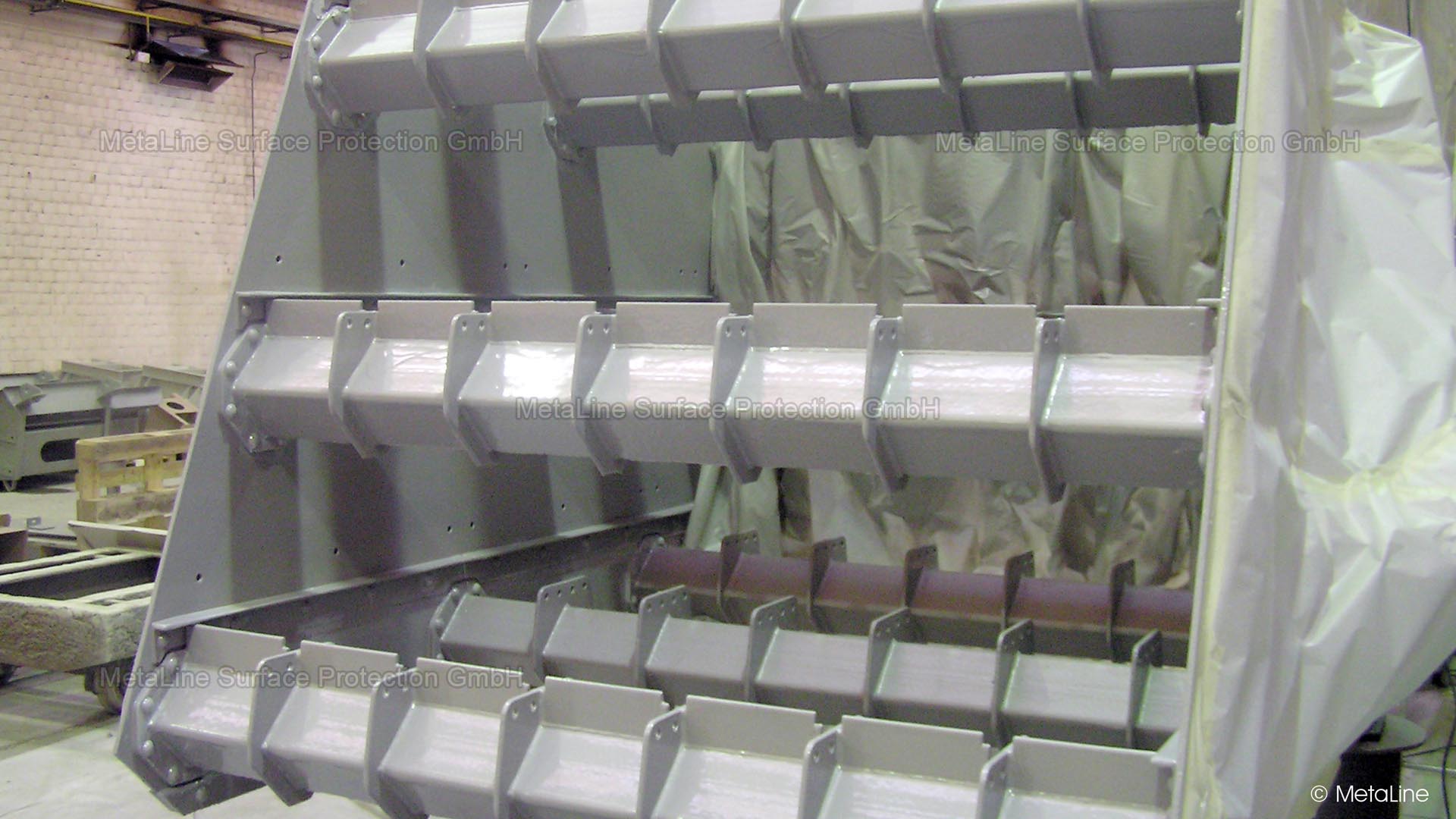

Sizer coating - multi-deck screening machine after complete coating with 3 mm MetaLine 785