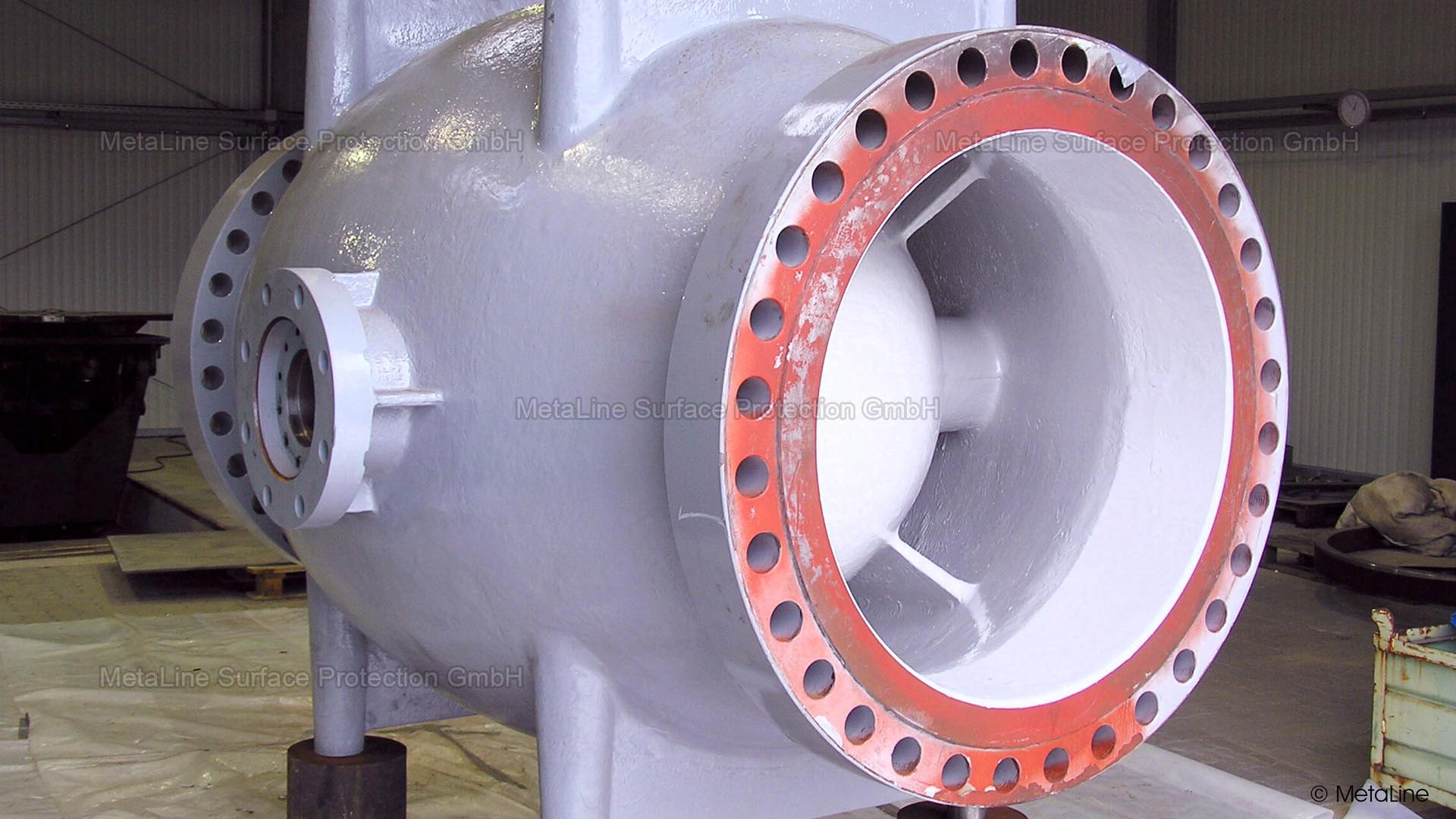

High-pressure ball valve of a drinking water pipe in Saudi Arabia – coated on the inside with 5 mm MetaLine 785

The toughest possible corrosion protection with MetaLine 785 - 3 mm layer thickness protects these large pumps from the high sediment content and the enormous flow volume. Conventional corrosion protection systems fail here within a very short time!

Saltwater resistant coatings – MetaLine 785 as seamless in-situ elastomerification for seawater piping in all diameters

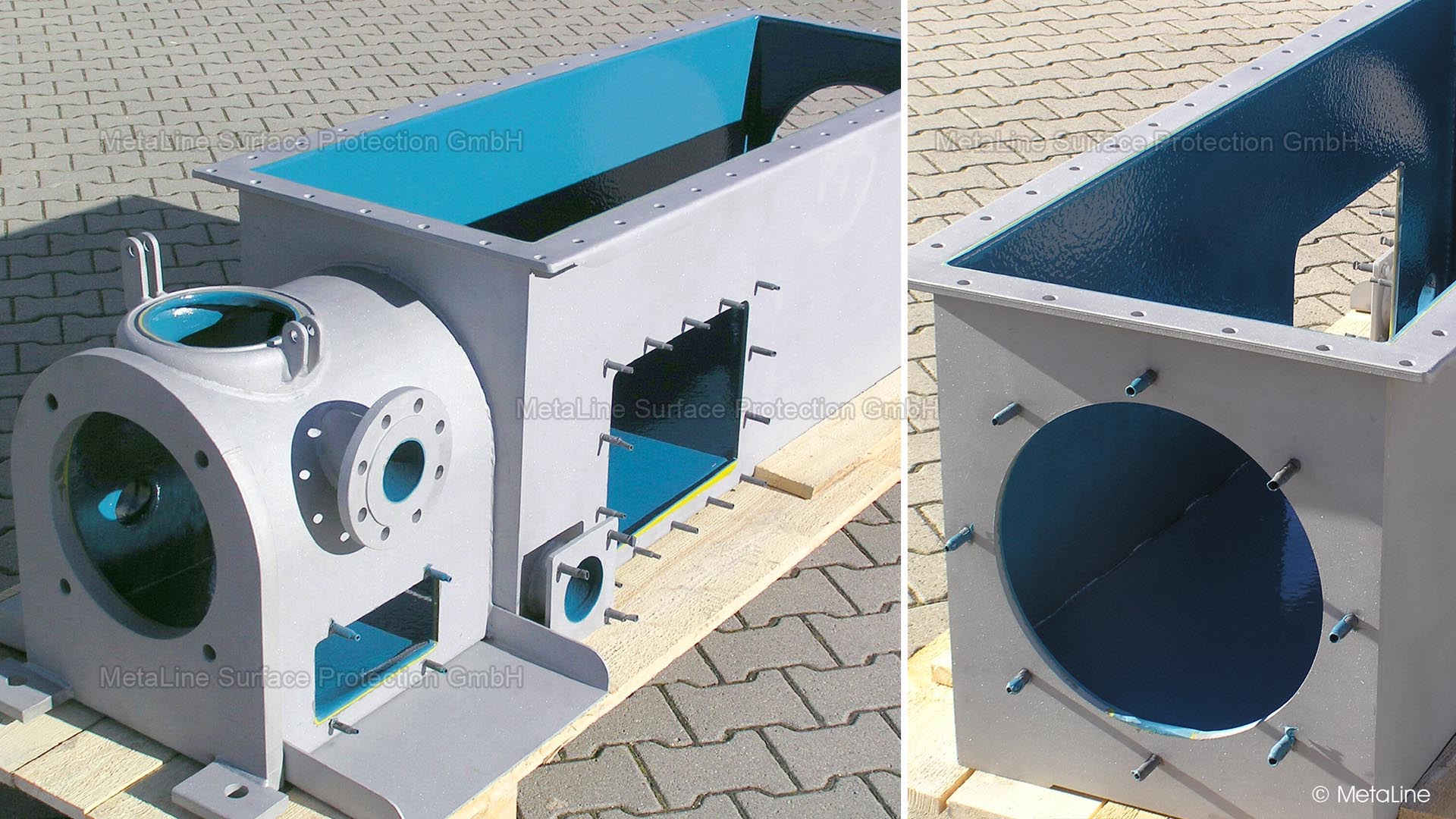

Strainer coating – MetaLine 785 had been used succesfully on these strainer units. Seamless, cold vulcanizing rubberlike characteristics was the customer's reason to vote against typical ceramic coats

1,5 mm MetaLine 795 applied in a very complex pump construction – thanks to our spray technology an easy task

Rock catcher of a pump casing for biogas systems – 4 mm MetaLine 785 protect the steel against corrosion and structural loss

Internal pipe coating - MetaLine Series 700 elastomer spray coatings - a case for almost all dimensions of single part coatings on site

Pipeline coating – MetaLine 785 is being used on site to seal and repair this sewage pipe made from concrete

Valve coating – MetaLine 795 used as heavy protective coating to protect against atmospheric corrosion in tropical costal areas

Pipe protection - what's good for the inside shields even better on the outside! MetaLine 795 as protective coating for buried pipes to withstand mechanical and corrosive loads

Coated on site with temperatures amounting to 40°C and more than 90% humidity with MetaLine Series 700 cartridge spray system

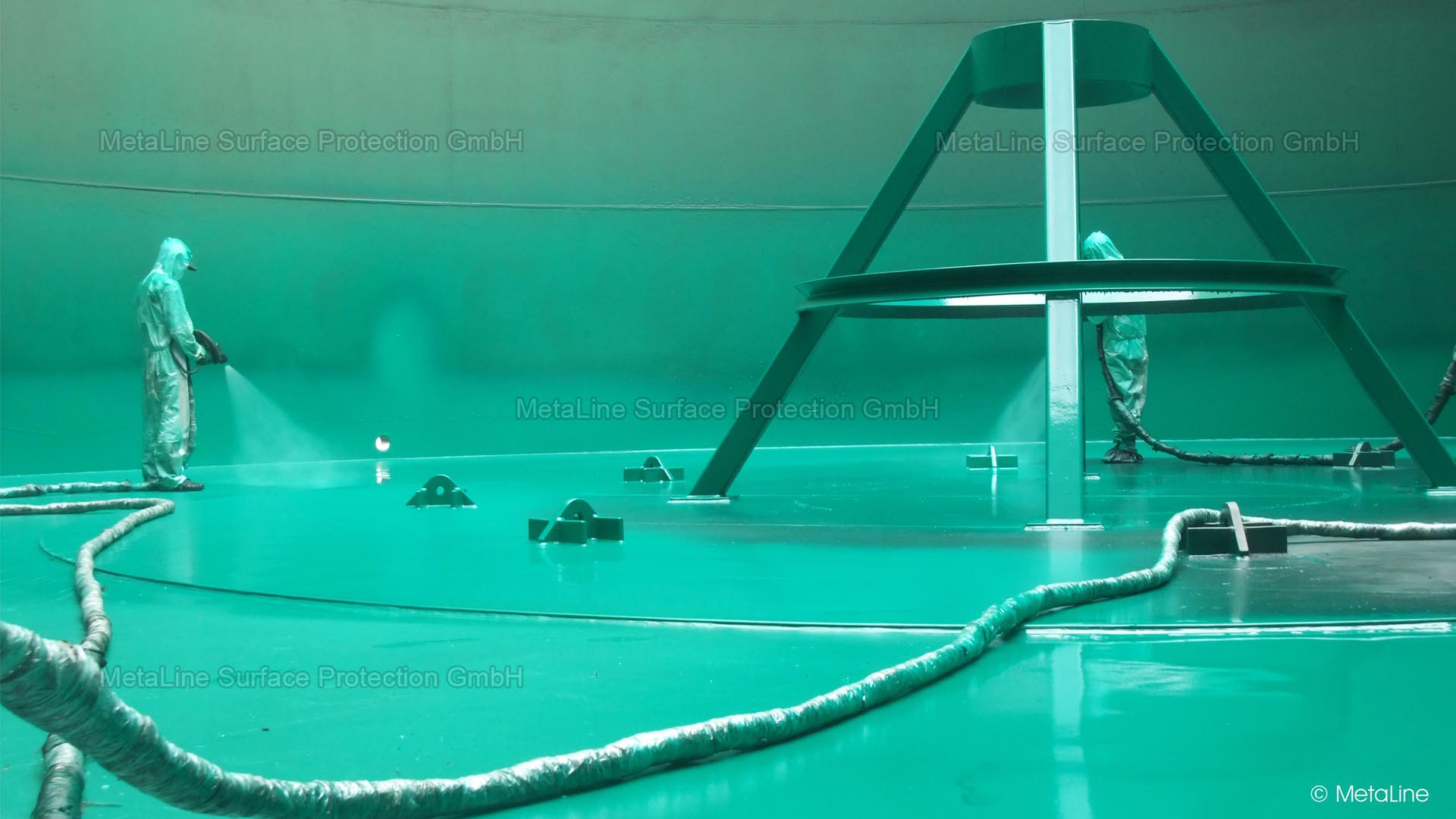

Seamless tank rubber lining - on-site lining of a tank with MetaLine 785 by means of a 2-component high-pressure spray unit. A case for specialists who attach importance to quality - not to a quick end of work!

Floatation cell coating - segment of a processing plant coated with MetaLine 785. Elastically protected against wear and corrosion - more is not possible!

Corrosion protection coatings are only as good as their application and the necessary substrate preparation. MetaLine relies on know-how transfer and intensive training - exclusively by ourselves!

Anti-corrosion coating - base of a street lamp coated with 1 mm (40 mil) MetaLine 795. The coating is intended to prevent damage from dog urine and to provide a better water seal to the tar

A "peelable" transparent corrosion protection - removal takes place at the end of the leasing period. The advantages? Less corrosion, resulting in a higher residual value of the equipment - that's how active cost saving on your machinery works!

Impeller coating with MetaLine 795 - 1 mm as high-performance corrosion protection on these water pumps. Not matched by any other product on the market in terms of smoothness and flow optimization. A rubber-like lining in a so far unique surface quality!

Snow plow coated with 2 mm MetaLine 785 and thus protected against salt, impact, sticking... and wild hogs

Agitator lining - special dimensions require special protection. An Archimedean screw during the protective treatment with MetaLine 590

Containment coating – an elastomeric coating with 2 mm MetaLine 785 protects this huge basin from deterioration and leakage

Filter coating - safely protected even at high flow velocities - with MetaLine Series 700

Ballast water tank coating – the seamless MetaLine "Tank-in-Tank" elastomer skin – 2 tanks in one – double holds better . . .

Corrosion protection in a penstock directly in front of the runner - paint systems are usually no longer sufficient here. Impact-absorbing properties, enormous adhesion to the substrate and above-average erosion resistance are required = MetaLine!

Corrosion protection on the rotor head of this type of helicopter - problem is sandy air during take-off/landing which leads to increased erosion of conventional galvanic coatings or paint systems. MetaLine elastomers are used here constructively ex works!