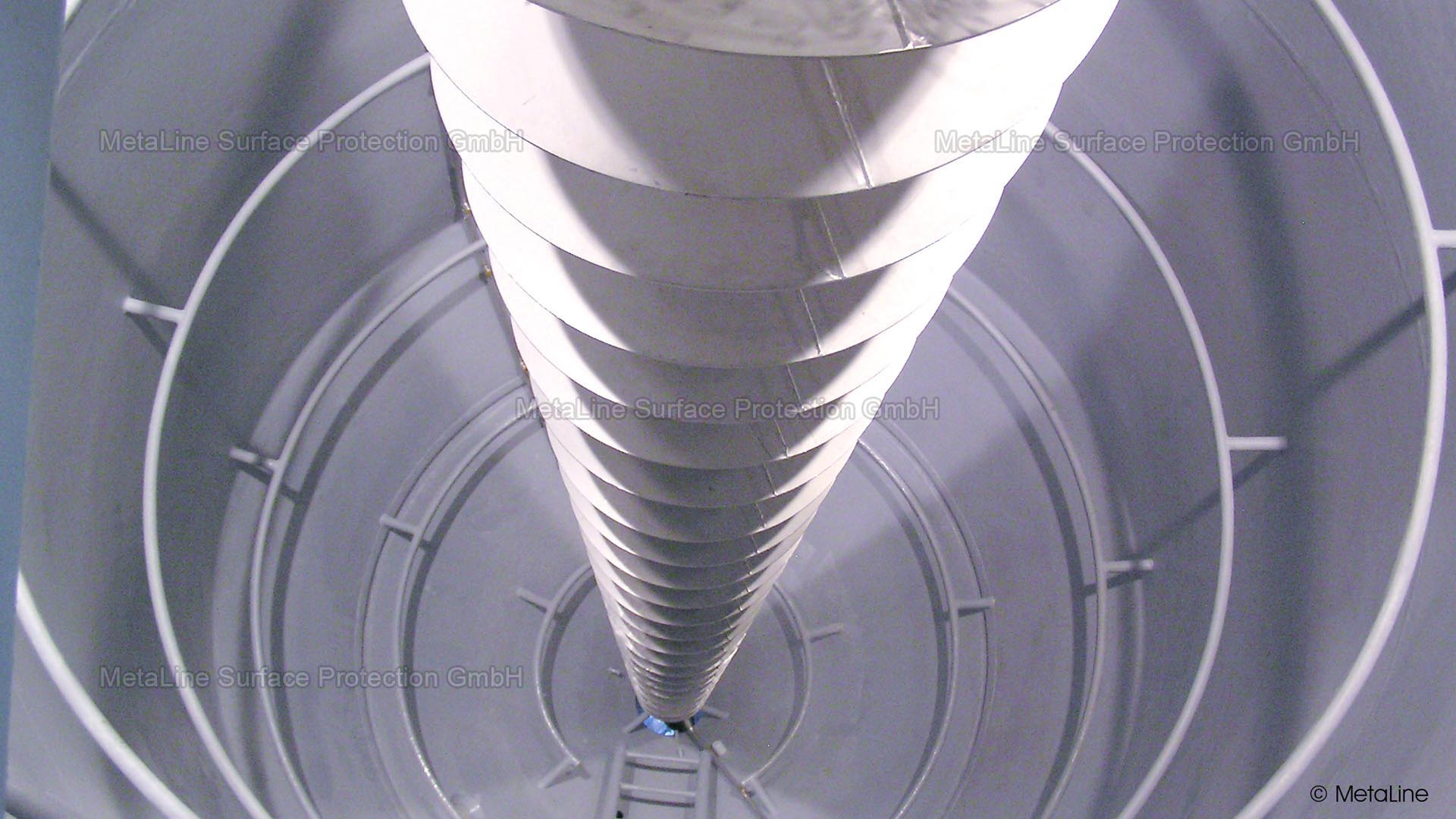

Screw conveyor coating - a more than 10 meter long screw conveyor coated with a combination of MetaLine 785 and 795. Application area is a municipal biowaste disposal system

Anti-stick roller coating - roller coated with 2 mm MetaLine 795 with attached drive rim. Seamless and realizable in almost any required color shade

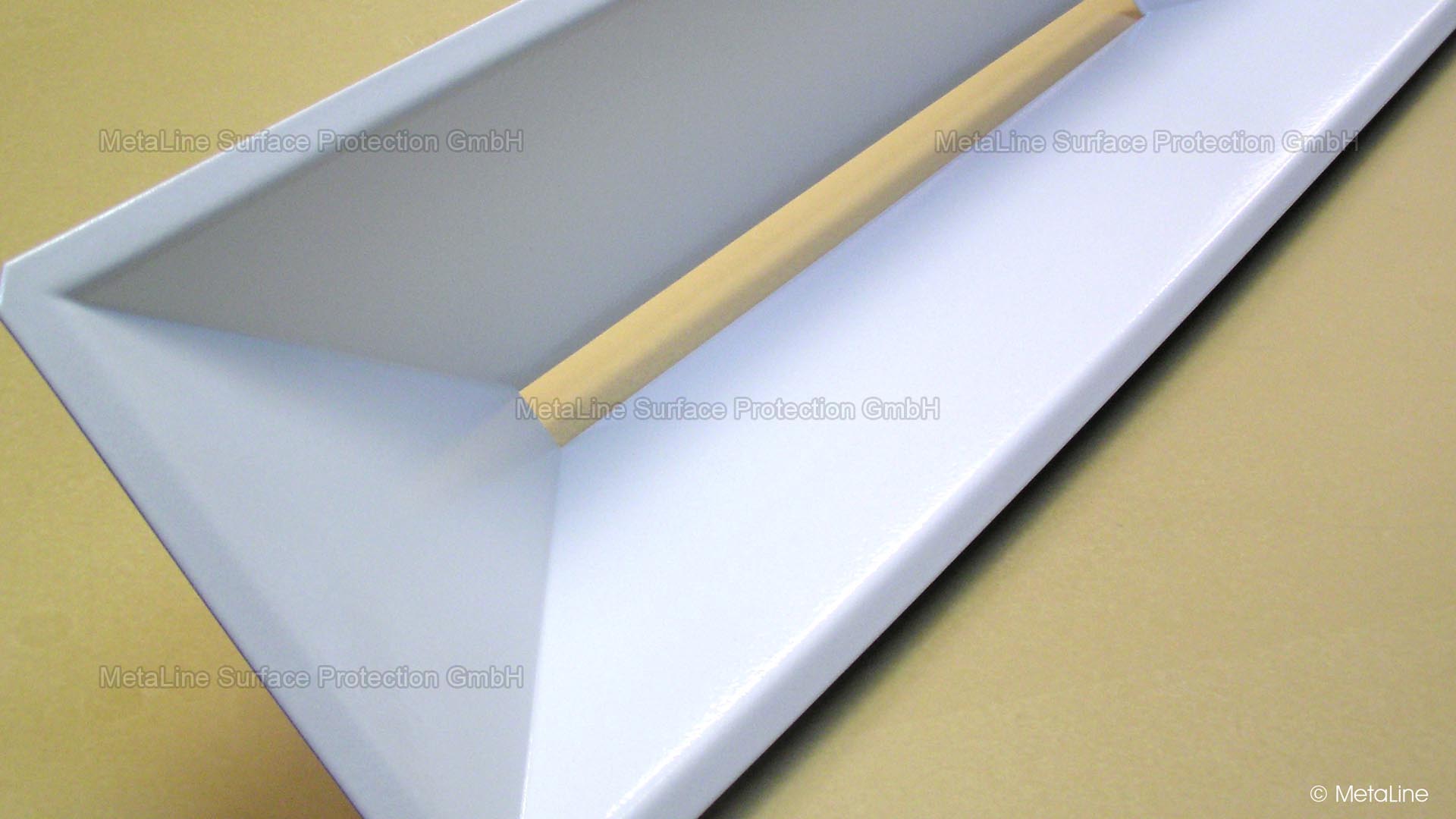

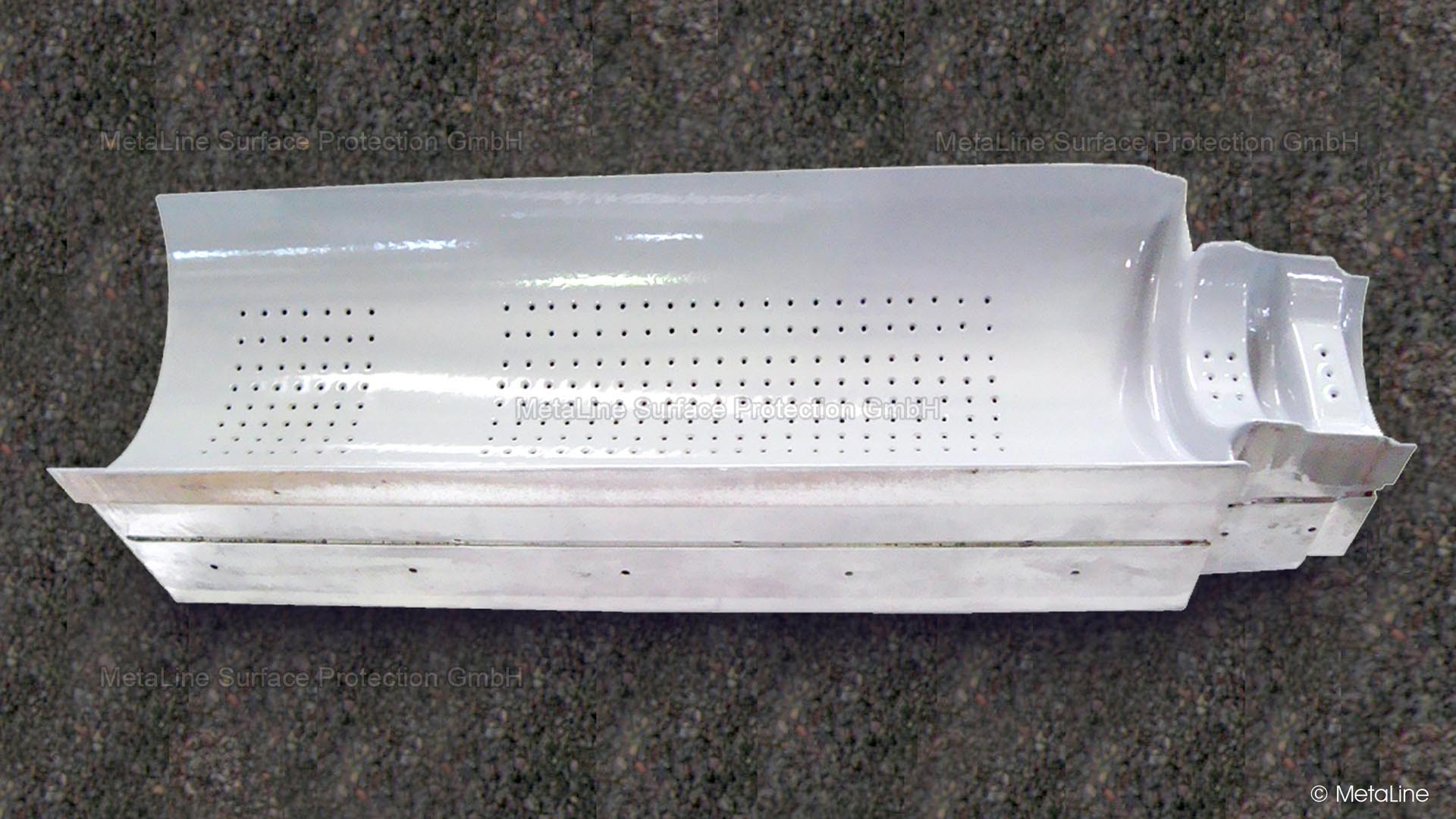

Pharmacy coating - a coordinated concept for surface protection & noise inhibition in the pharmacy - 2 mm MetaLine 785 on this transfer chute protects against tablet breakage and discoloration

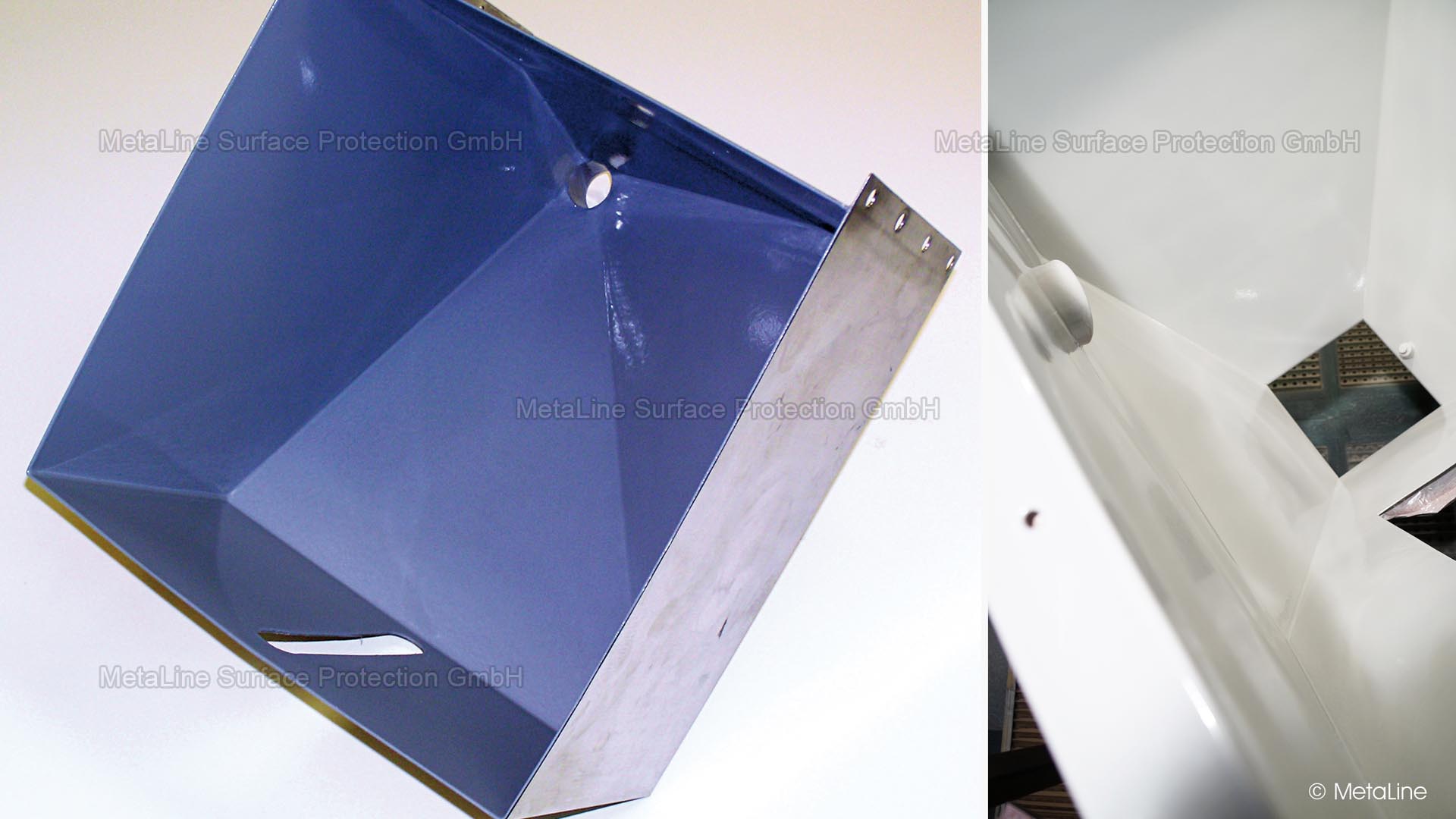

Magazine coating - transfer container of a world famous crystal manufacturer slide coated with 0.8 mm MetaLine 795. Exceptional precision is required for the fine crystals

Sticking protection - elastomeric coatings have the remarkable ability to shake off hard coatings due to the internal movements during pressure changes. Unfortunately, this is not possible with soft adhesions!

Anti-stick - every adhesion is unfortunately different and every variation in moisture content, pressure, temperature or chemical composition leads to a changed situation. There is not THE one coating that can do everything - there are only specialists like us who can take care of your problem professionally!

Non-stick coating - 1.5 mm MetaLine 598 ensure smooth transport and prevent production media from sticking

Non-stick coating - MetaLine is not only engaged in the development and application of anti-adhesive coatings. Rather, we impart know-how to our sales partners and customers. We support and train from the first to the last step - in the interest of the best possible results.

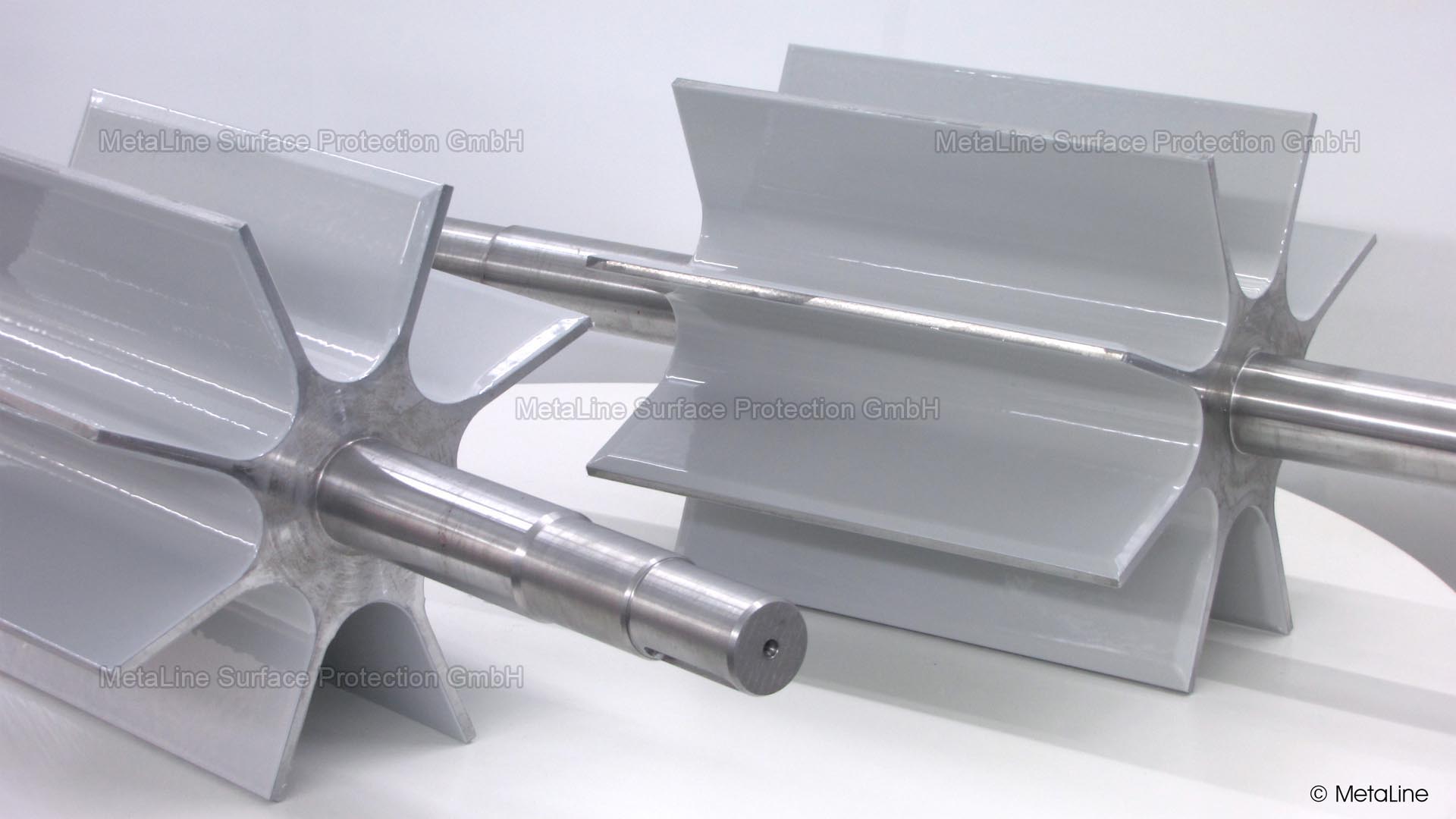

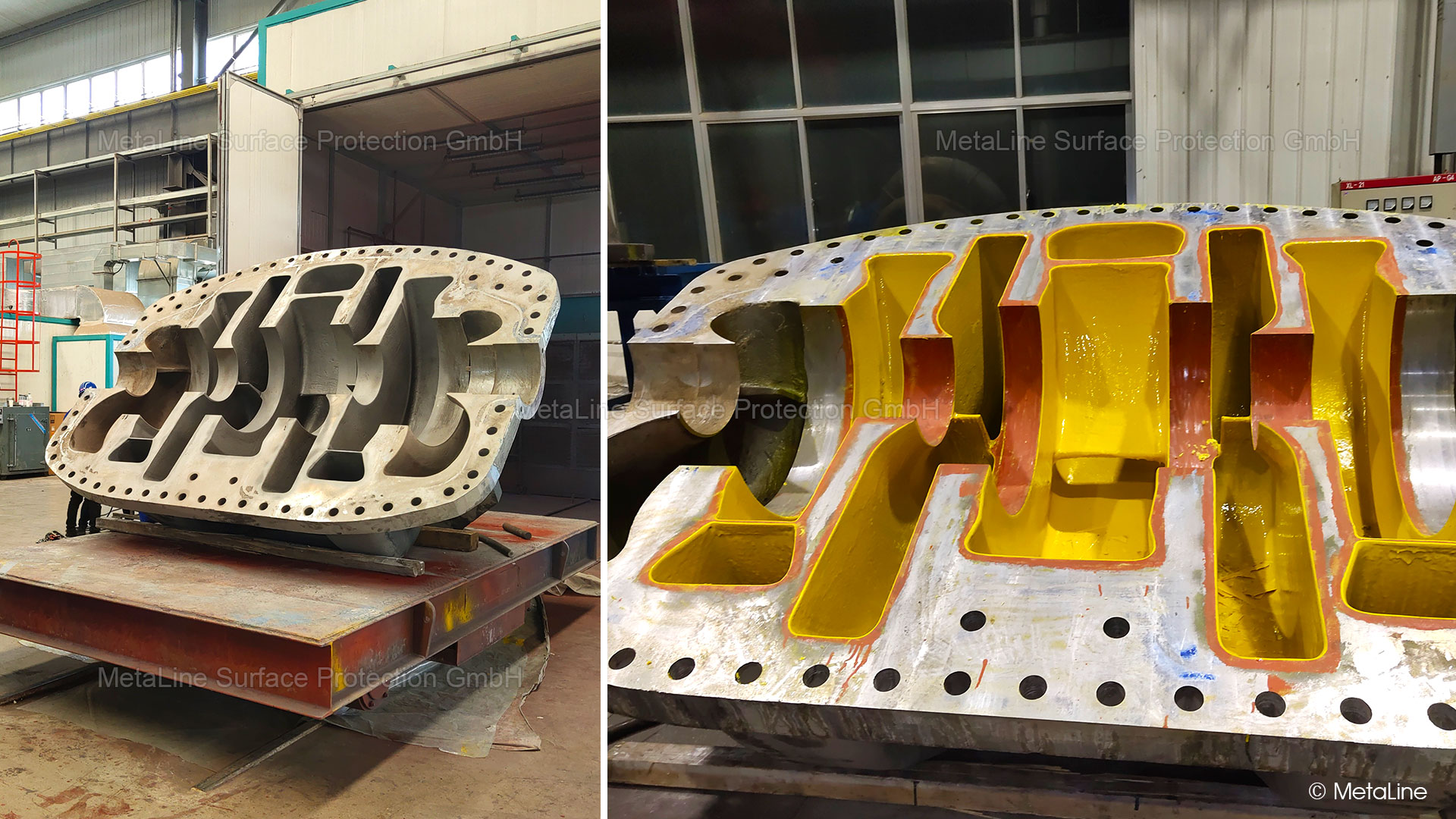

Mixer coating - 3 mm MetaLine 795 protects these kneading arms from wear and disturbing product buildup

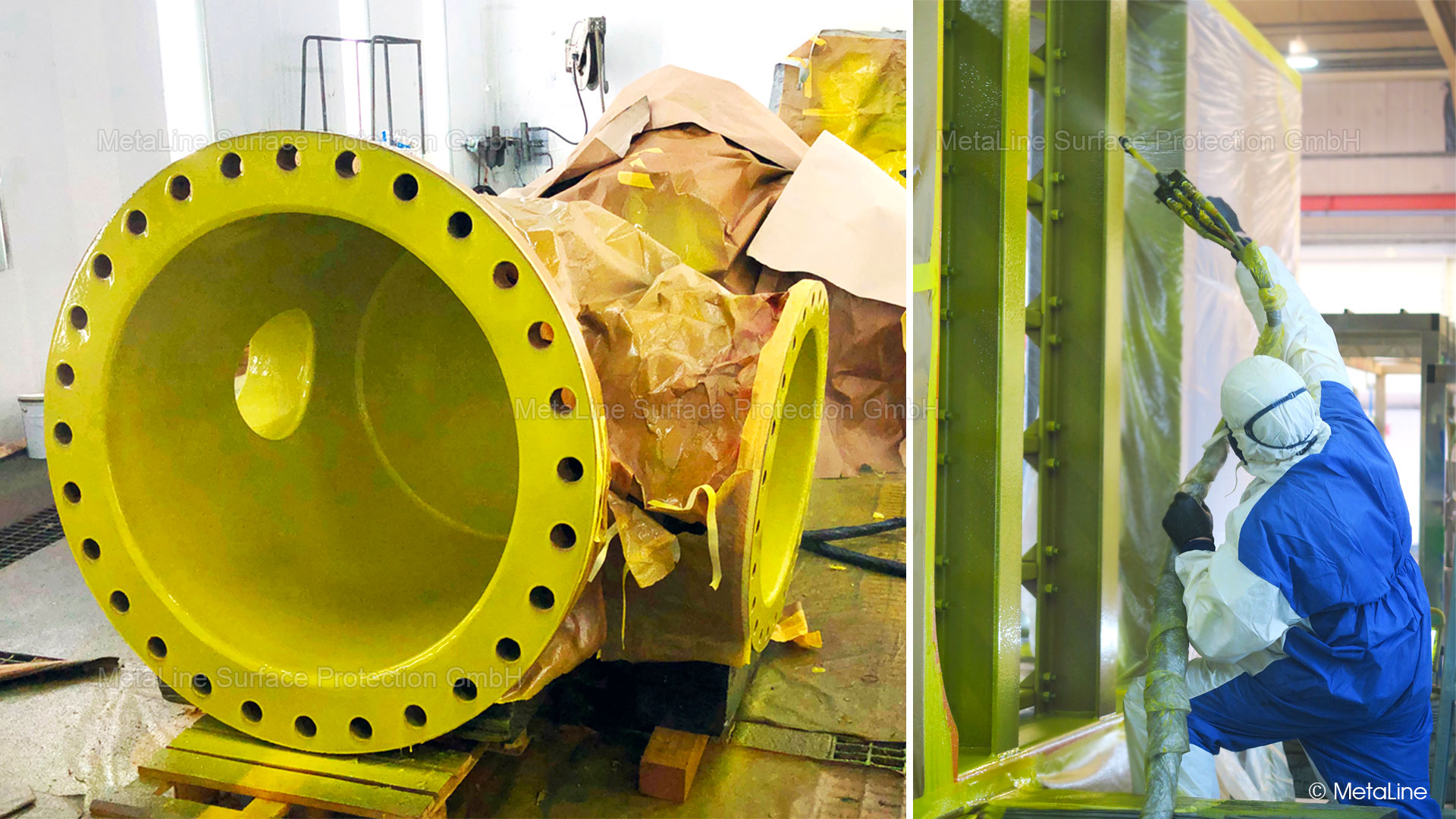

Fan coating - MetaLine's low-pressure spray technology is unbeatable, especially for difficult geometries. Variable coating thicknesses - thicker where wear attacks and thinner where only the anti-stick properties matter

Rotary valve coating - MetaLine 795 in a thickness of 1 mm protects this runner of a rotary valve from material build up and sticky products

Construction machines – that's where MetaLine coatings can prove their worth

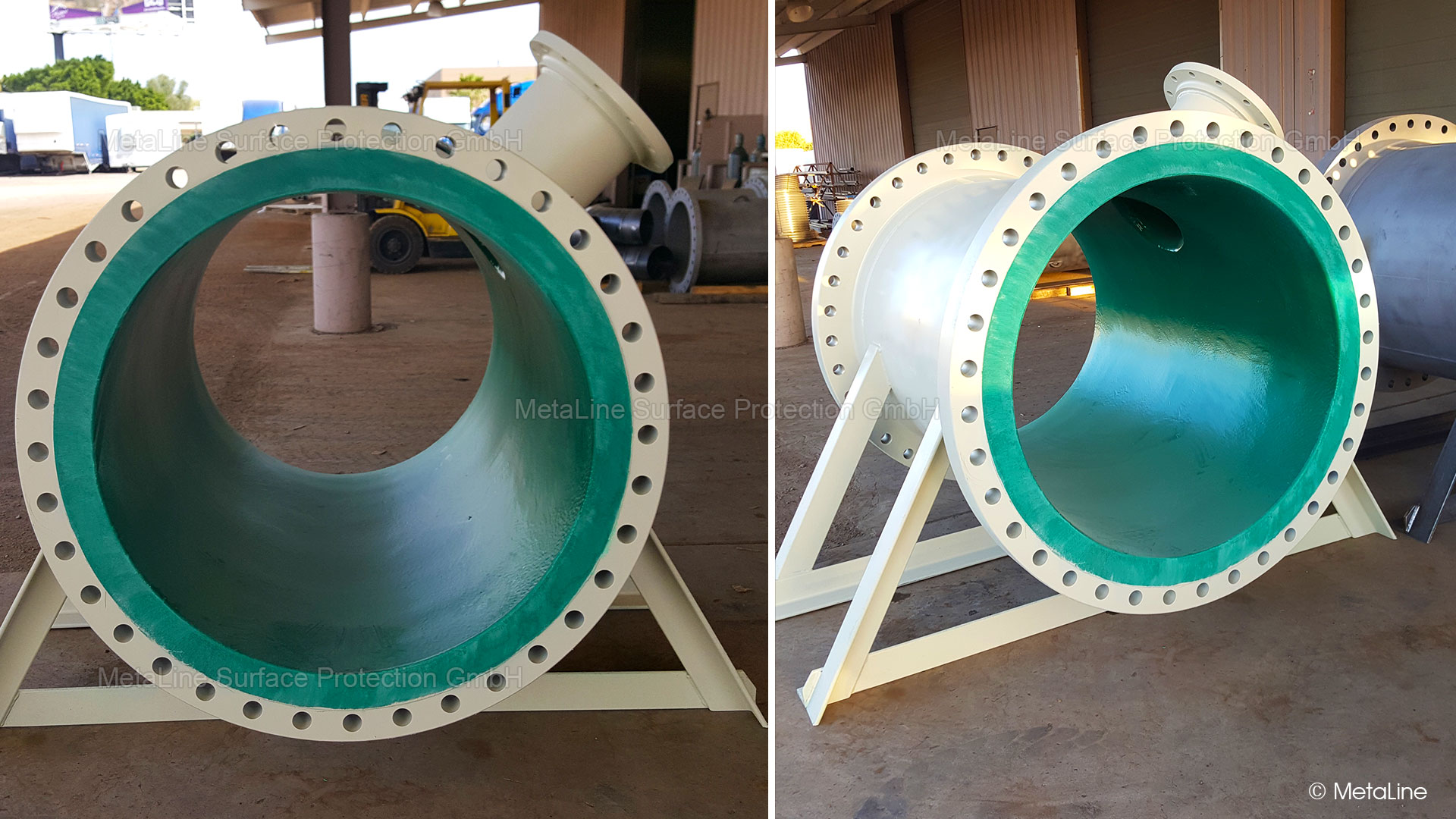

Loading pipe coating - telescopic pipe package coated with 2 mm MetaLine 795 as anti-stick coating and wear protection for cement production

Dumper coating - any questions about the load capacity of MetaLine 795? What else can you apply yourself on site in this quality?

Container lining - smooth, non-stick, biologically resistant. MetaLine 795 a case for composting waste. Permanent resistance to biomass and its secretions is given

Excavator bucket coating - MetaLine 795 as an efficient adhesion protection for very clayey soils. However, the bucket can then no longer be used for normal excavation work

Non-stick coating - for particularly sticky products. MetaLine 795 in 3 mm coating thickness optimizes slipping on this bucket and increases the working speed

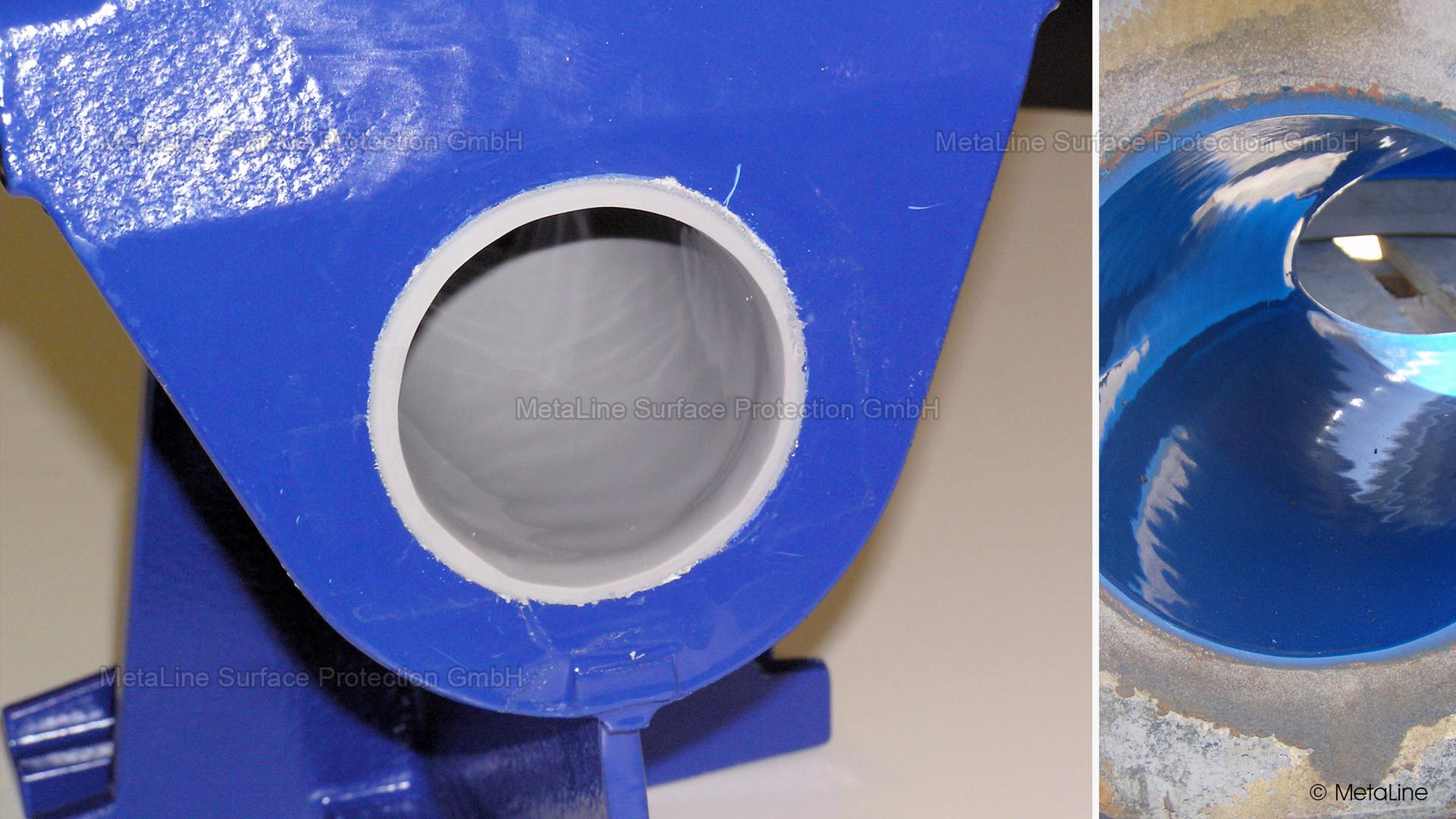

Anti-fouling coating - seamless saltwater-bearing area of a pump system lined with MetaLine 760. Limescale build-up and fouling of the narrow pipe diameter no longer stand a chance

MetaLine 598 applied in 1 mm as non-stick coating onto this ceramic powder container silo

Container rubber lining - lining of a metallic silo with MetaLine 590. The objective is an absolute absence of metal in order not to contaminate the stored plastic granulate!

Food compliant coating - granular foodstuffs are often screened. Right at the top of the specifications is breakage protection, e.g. of nuts. No problem with MetaLine 785 - even FDA conforming.

Snow plow coating - snow blade coated with 2 mm MetaLine 785 and thus protected against salt, impact, sticking and corrosion.

Impact protection coating - injury and impact protection for people and production goods. A soft coating with MetaLine 760 makes it possible

Roof tile mold coating with MetaLine 598 - when it comes to protecting steel from attack, there should be a name - MetaLine Germany

Multi-functional coatings - with a coating you can usually cover several technical topics. Nevertheless, you should always inquire as precisely as possible and as narrowly as possible. The chance to get a really suitable solution and no rejection increases with it!

Coating of plastic - the coating of polymer surfaces with a MetaLine elastomer can also yield remarkable advantages. With the plastic, one must first distinguish between polar and di-polar plastic. If you do not know the difference, you have come to the right place!

Antiadhesive coating - if possible, always means optimizing the geometry and surface design. As in this case, the rounding of a flow-disturbing edge!