Tire repair - Solid rubber tires generally have a long service life. And yet there is always a need to repair damage in good time. Especially with rental machines where customers have a particularly critical eye on the condition of the tires when they take delivery of the machine

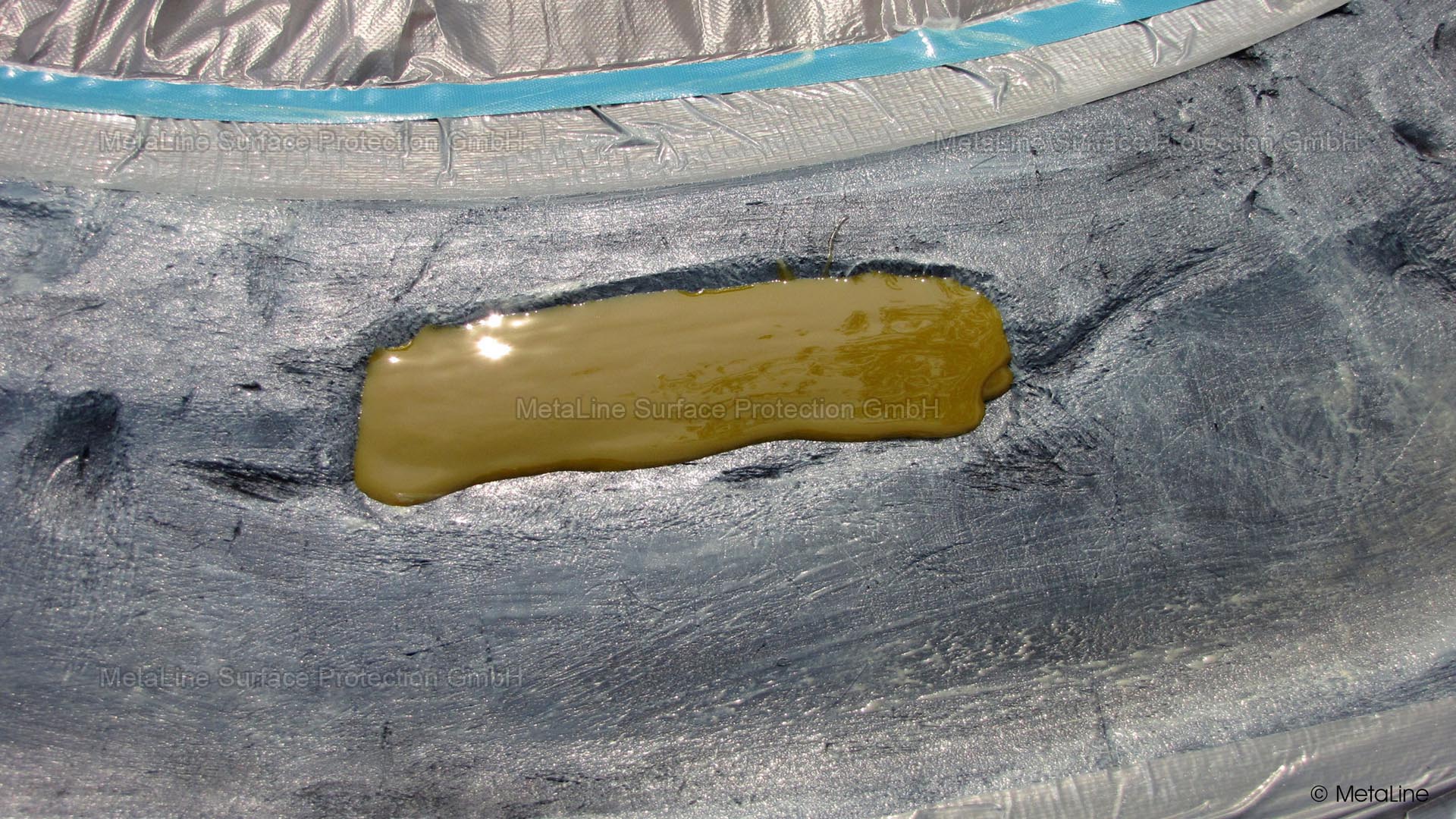

Tire repair - cut repair on the front wheel sidewall of an off-road forklift with MetaLine 680. These local repairs are not just cosmetic, but are intended to prevent the damage from progressing. So that a little does NOT become a lot!

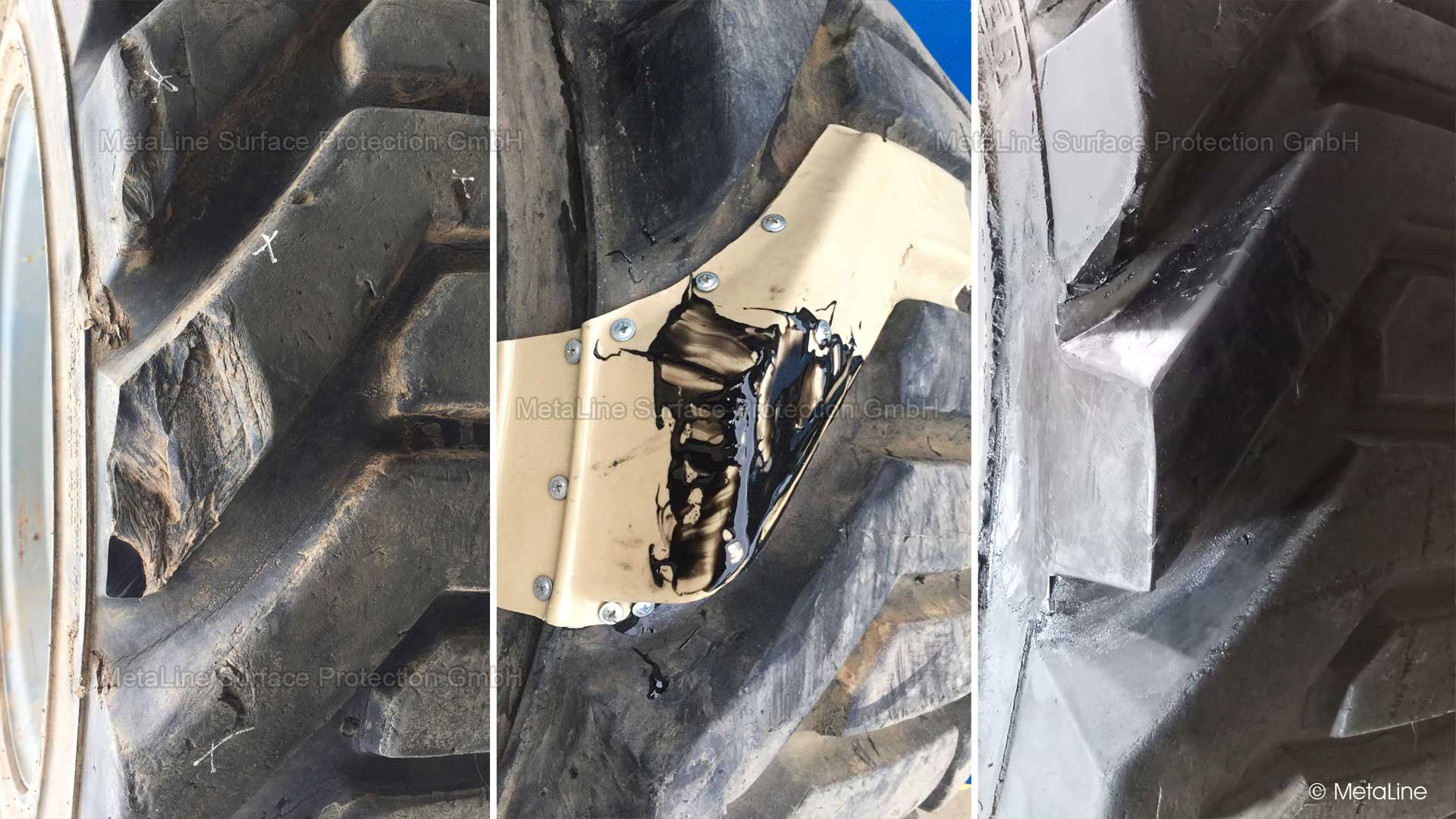

Tire reprofiling - the torn-out thread of a solid rubber tire was reproduced with MetaLine 680. The repair was carried out directly on site in a quarry. Commissioning can generally take place after approx. 24 hours (at 20 °C / 68 °F)

Damage to the tread of a solid rubber tire. With the necessary knowledge and our process, a perfect repair option with MetaLine 680. Quick and easy? No - certainly not! We don't sell illusions, but proven technical solutions. Elaborate, but good!

Tire repair. Would you like to seal a truck tire? NO, not with us! MetaLine technology is limited to solid rubber tires that are used outside of legally regulated road traffic. For good reason - because safety is our top priority and you cannot look inside the tire during the repair!

Tire repair - The MetaLine process is suitable for repairing partial damage. But not to fundamentally reinforce the strength of overloaded tires. Every technology has its limits . . .

Repairing a solid tire - Do you have questions about this image or this application? Simply take a screen shot and send it to us by email. We will get back to you - we promise!

Tire repair - Partial repair of sidewall damage. Sealing with MetaLine 680 must be carried out in good time before irreparable damage occurs

Solid tire repair - the extent to which you carry out repairs is at your discretion. However, possible damage to the static stability must be checked beforehand. We are repair specialists and not sellers of adhesives!

Tire overhaul - cut on the outer tire sidewall. The steel reinforcement is already visible. Our process is aimed in particular at rental companies of lifting and construction machinery, so that they do not have to charge their customers an additional new tire for every little thing

Tire damage - the repair was carried out directly on site. Roughening and cleaning the sidewall are the first steps on the tire. A precise step-by-step procedure is essential. Success is not usually based on sloppiness . . .

Tire coating - due to the large amount of damage, the entire sidewall of the tire was coated. The MetaLine process is color-customizable and can also be used on white solid rubber tires

Forklift tires - this repair was carried out using a template to obtain the tire marking. The template was taken from an intact tire. Somewhat time-consuming but customer request . . .

Tire tread repair - a proven and logical measure on solid tires. What can go wrong? Little - in the worst case, the tire is as it was before the repair - nothing can get worse. The risk is very low compared to the chance of success!