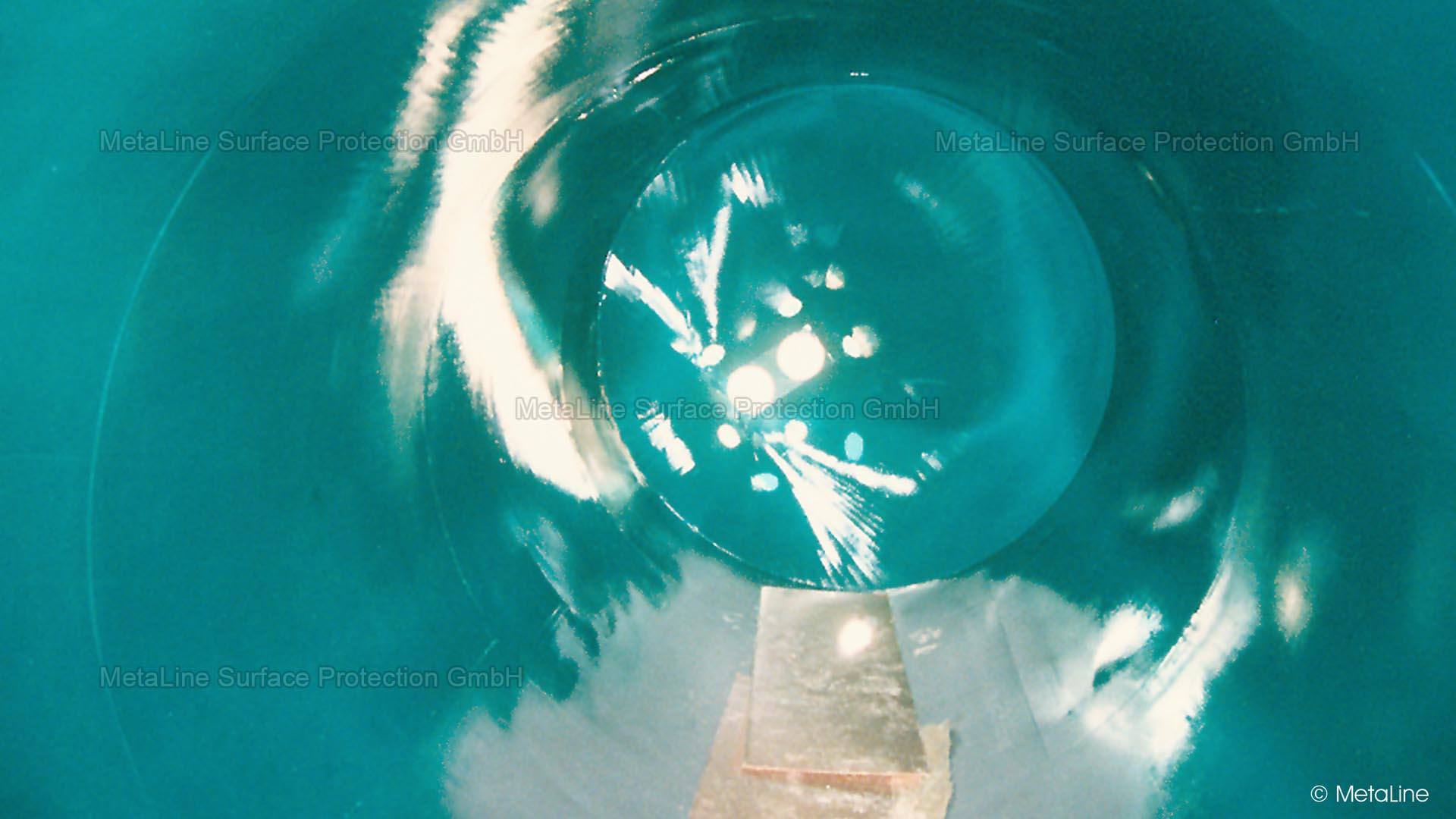

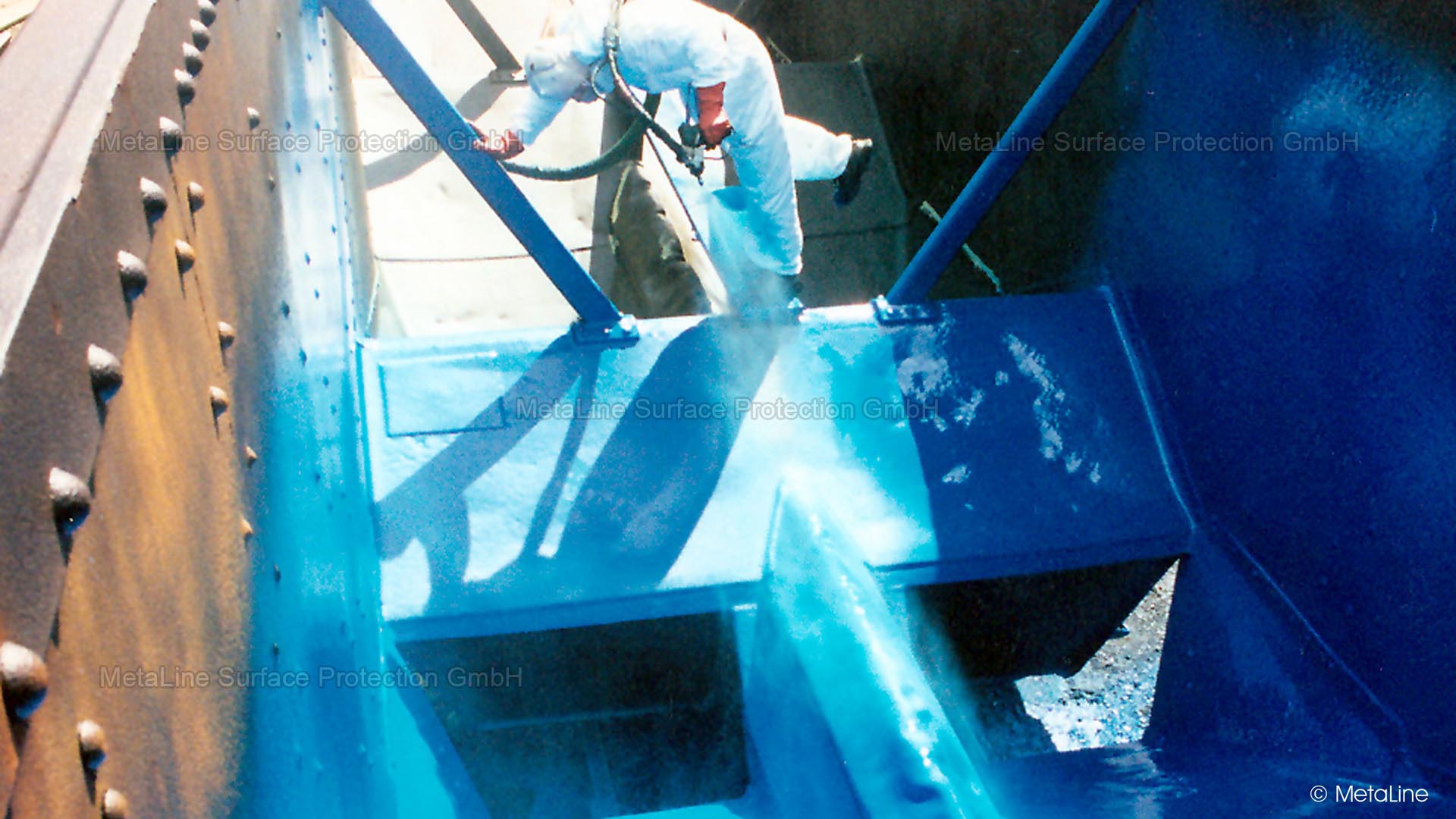

MetaLine stands for professional coating quality and professional application technologies – here during the installation of MetaLine 785 in a large floatation tank

Stainless steel tank protected on the inside with MetaLine 700 against chloride corrosive attacks

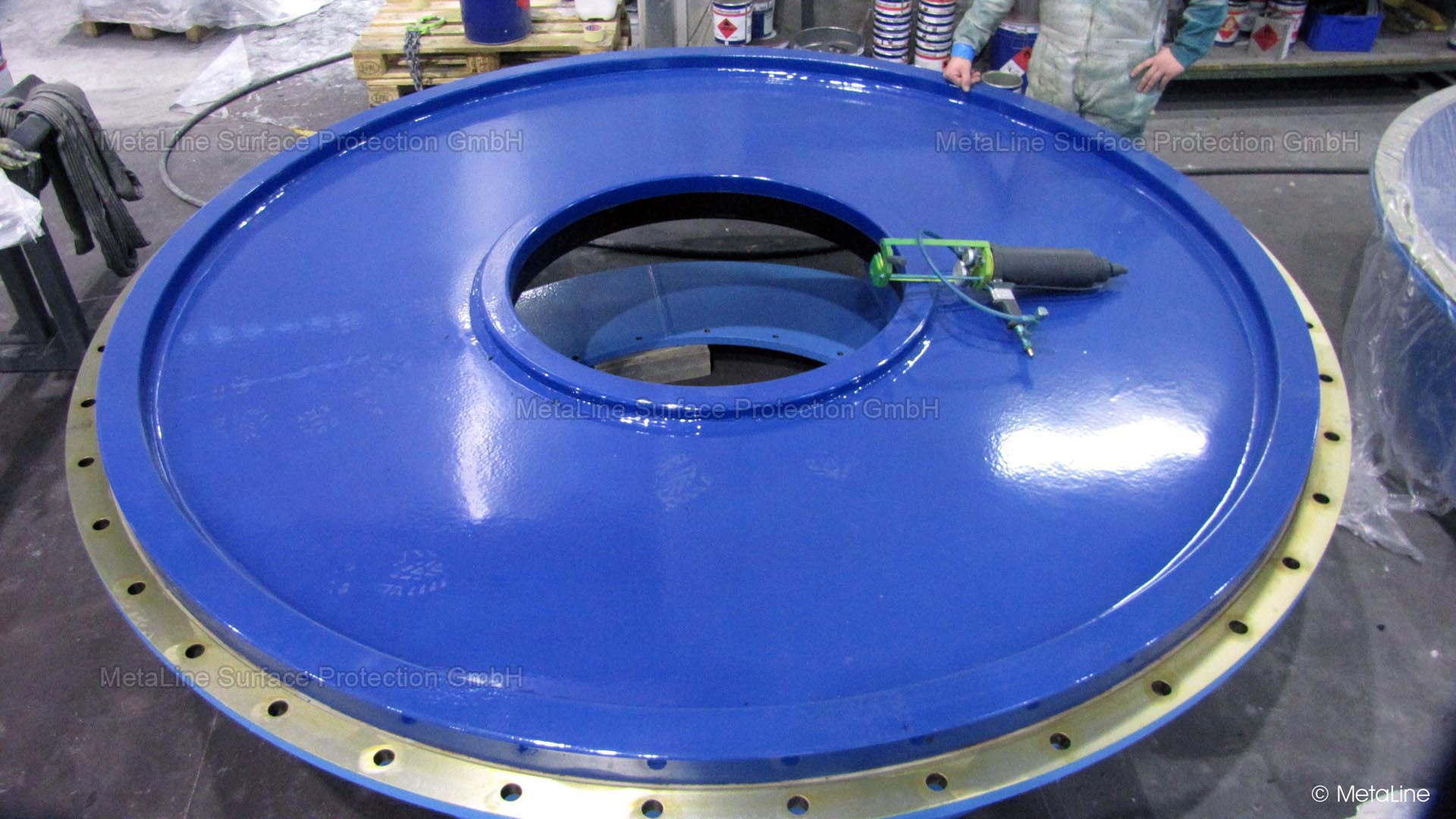

Coated with MetaLine Series 700 in the wear area – offers protection and avoids cost

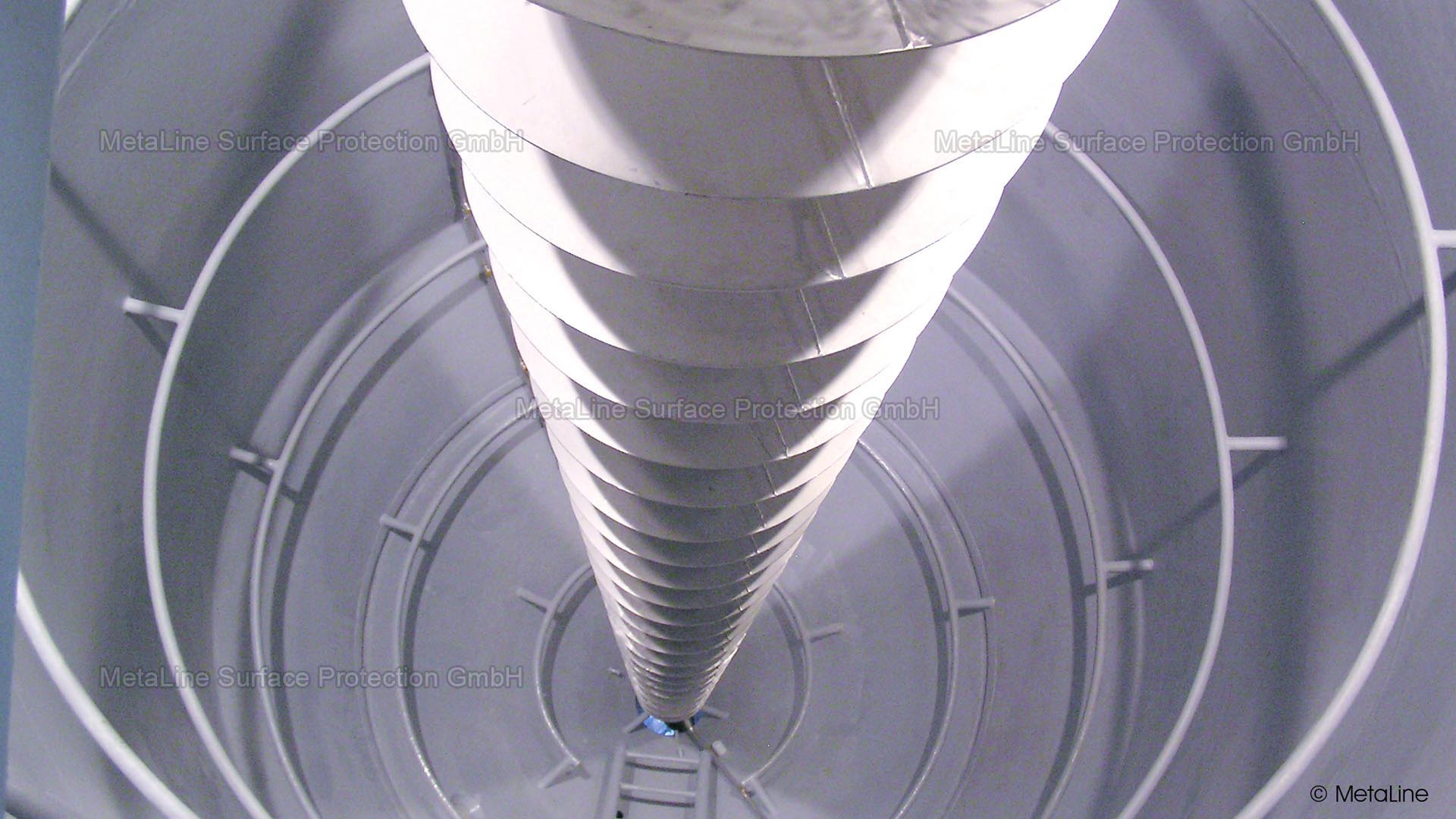

Silo wagon coated on the inside with MetaLine Series 500 against corrosion, chemical attacks and sticking matter

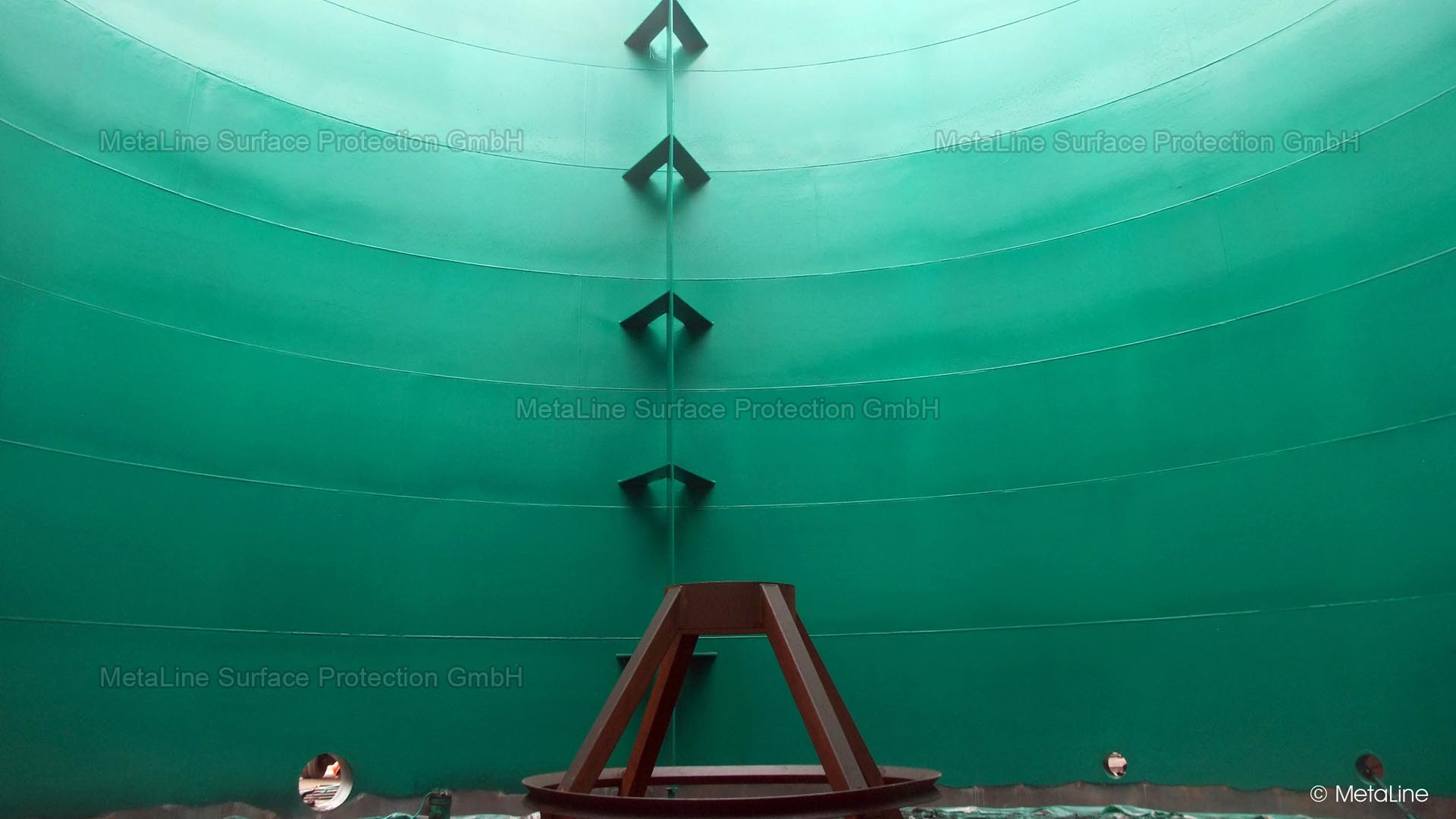

Tank lining – MetaLine 795 is an extremely efficient coating solution to avoid damages to the steel construction on one side and to ease surface cleaning on the other side

On-site lining of a bottom tank with MetaLine Series 700

Coating of a tank dome – a homogenous coating of 2 mm MetaLine 785 protects against aggressive forces caused by solid, liquid or gaseous substances

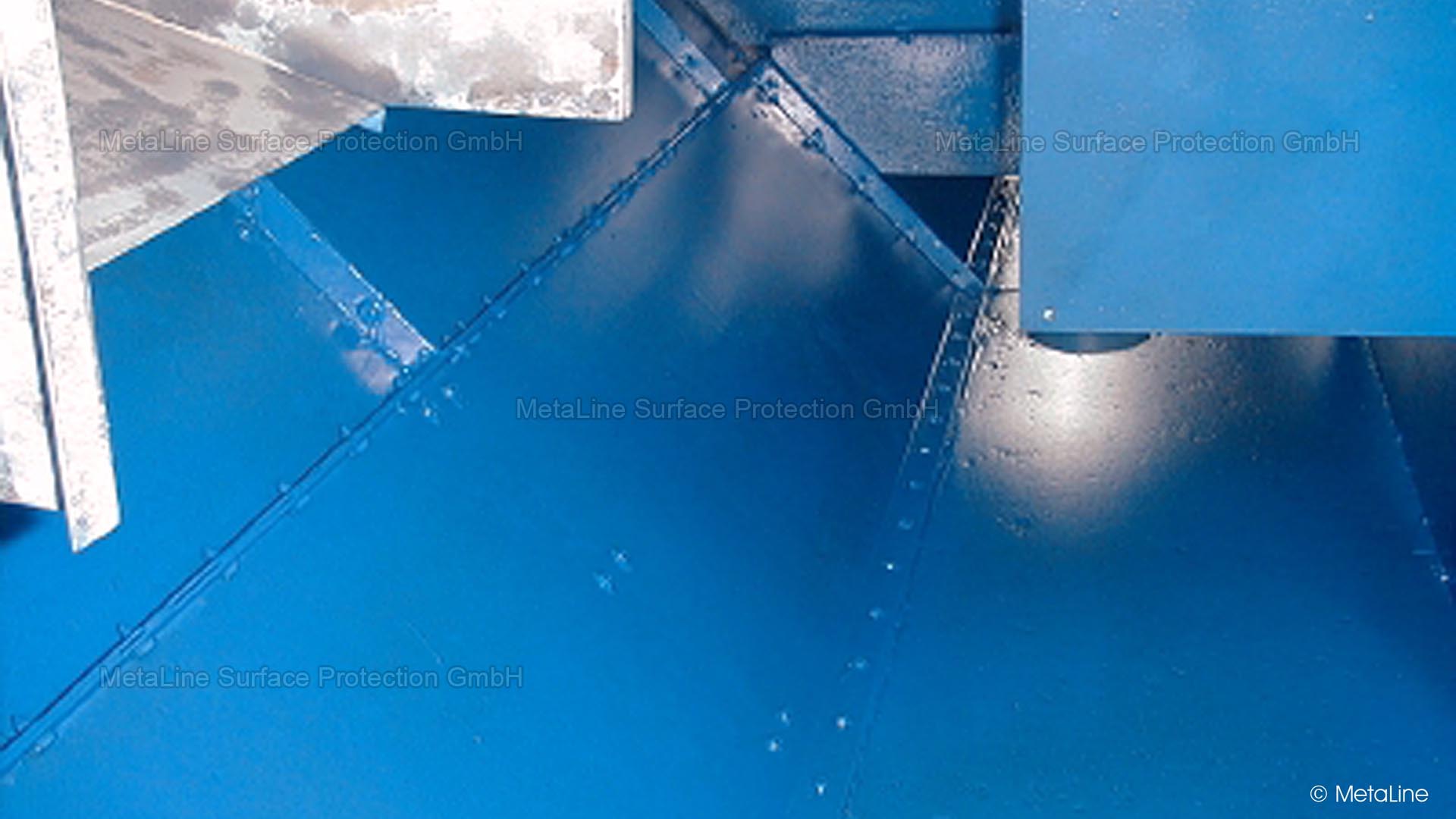

A complete clearing basin coated with MetaLine Series 700 – offers leak and tear protection and protection against attacks

Lining of a plastic silo with MetaLine Series 700

Tank coating – MetaLine 795 in a thickness of 1,5 mm protects this huge tank from leackage and corrosion

If non-stick properties and good gliding behavior are a must – MetaLine 795 is to be used

Tankcoatings – a job for experts. The MetaLine Series 700 cartridge spraysystem in use for the repair of a worn rubberlining inside a chemical process reactor

MetaLine Series 700 seals even difficult constructions – as is shown with this rivet layout

Neutralization basin coated with MetaLine 100 XTM – concrete resistant like stainless steel thanks to MetaLine

Secondary containment lining - MetaLine 100XTM seals, waterproofs and protects concrete surfaces from rising aggressive liquids.

Tank lining – a full coating with MetaLine 100XTM protects from chemical as well as biological corrosion and is relatively easy to install