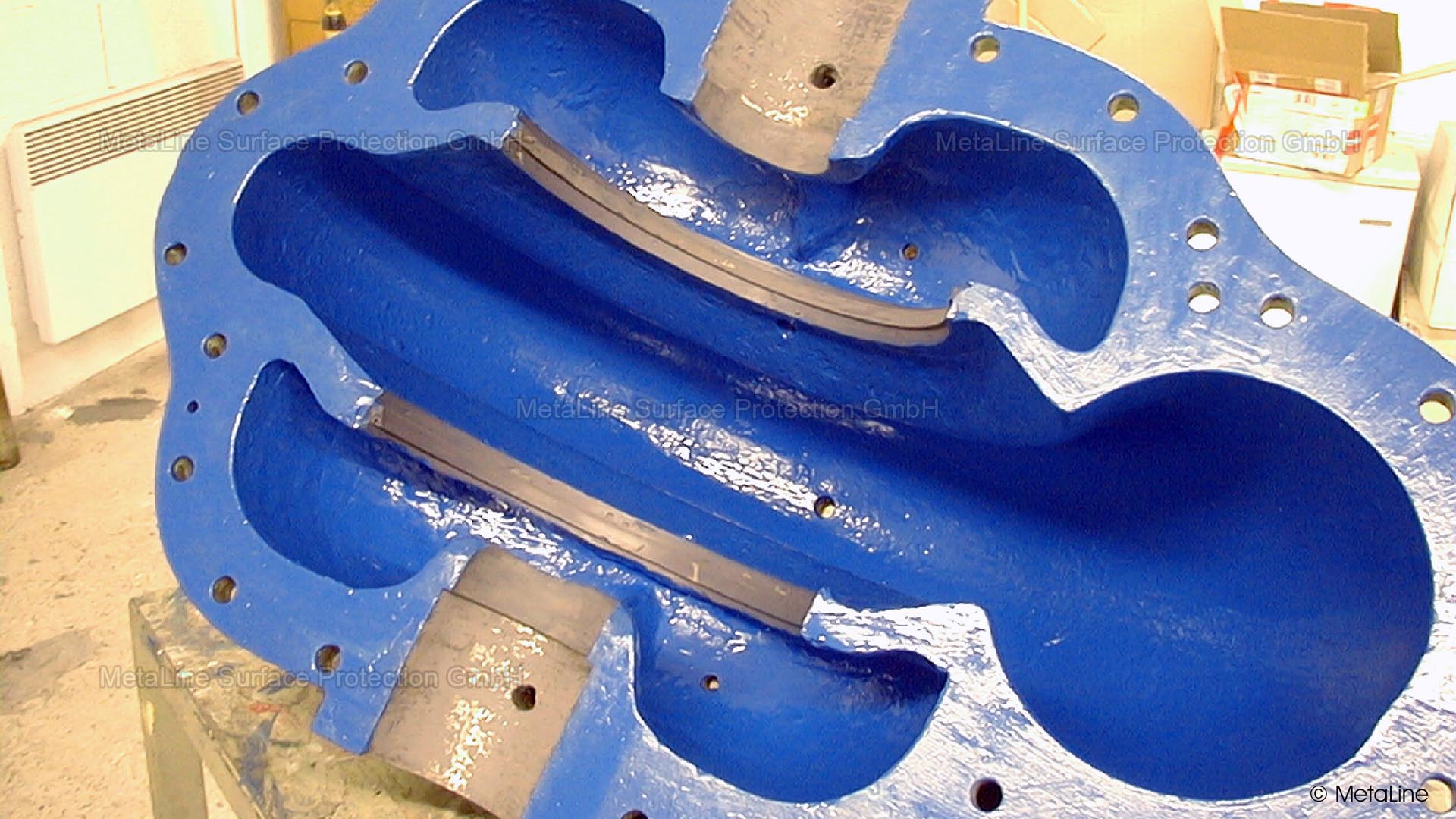

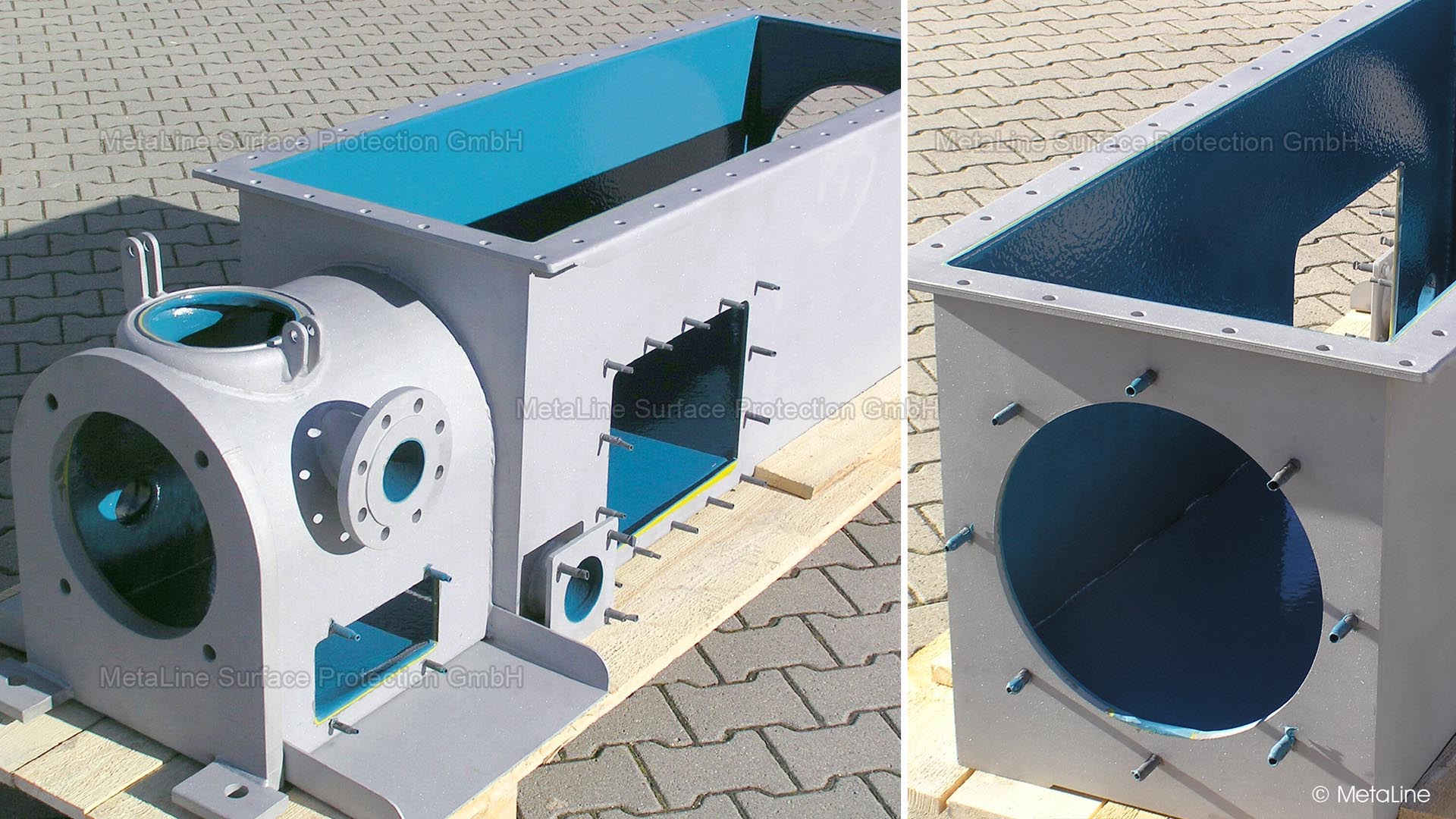

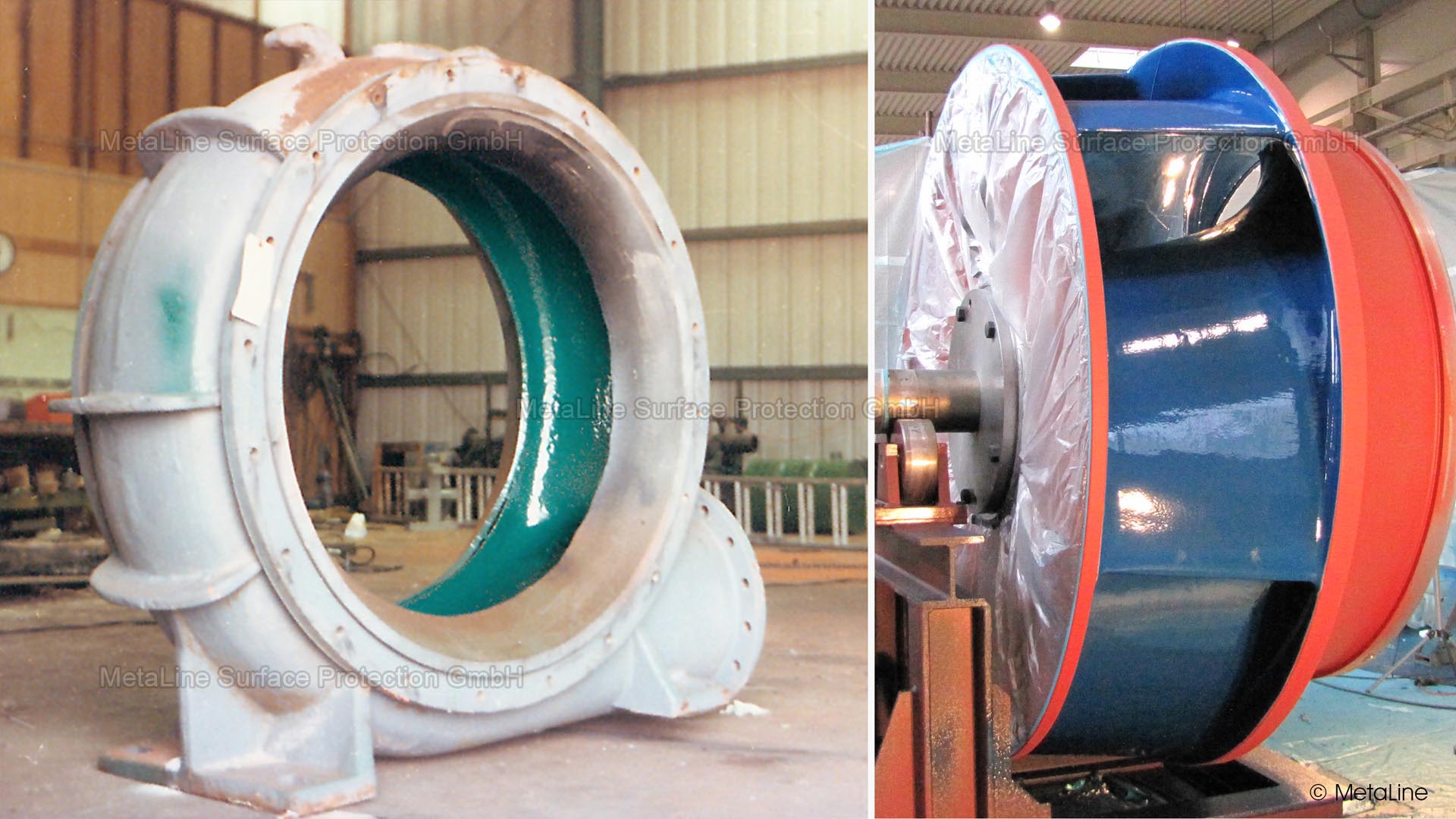

Axially split pump housing coating - MetaLine 785 was the first choice for the coating of this large pump. Why? The service life advantages over the previously available epoxy ceramic coatings and the better efficiency due to the extremely smooth surface were the deciding factors

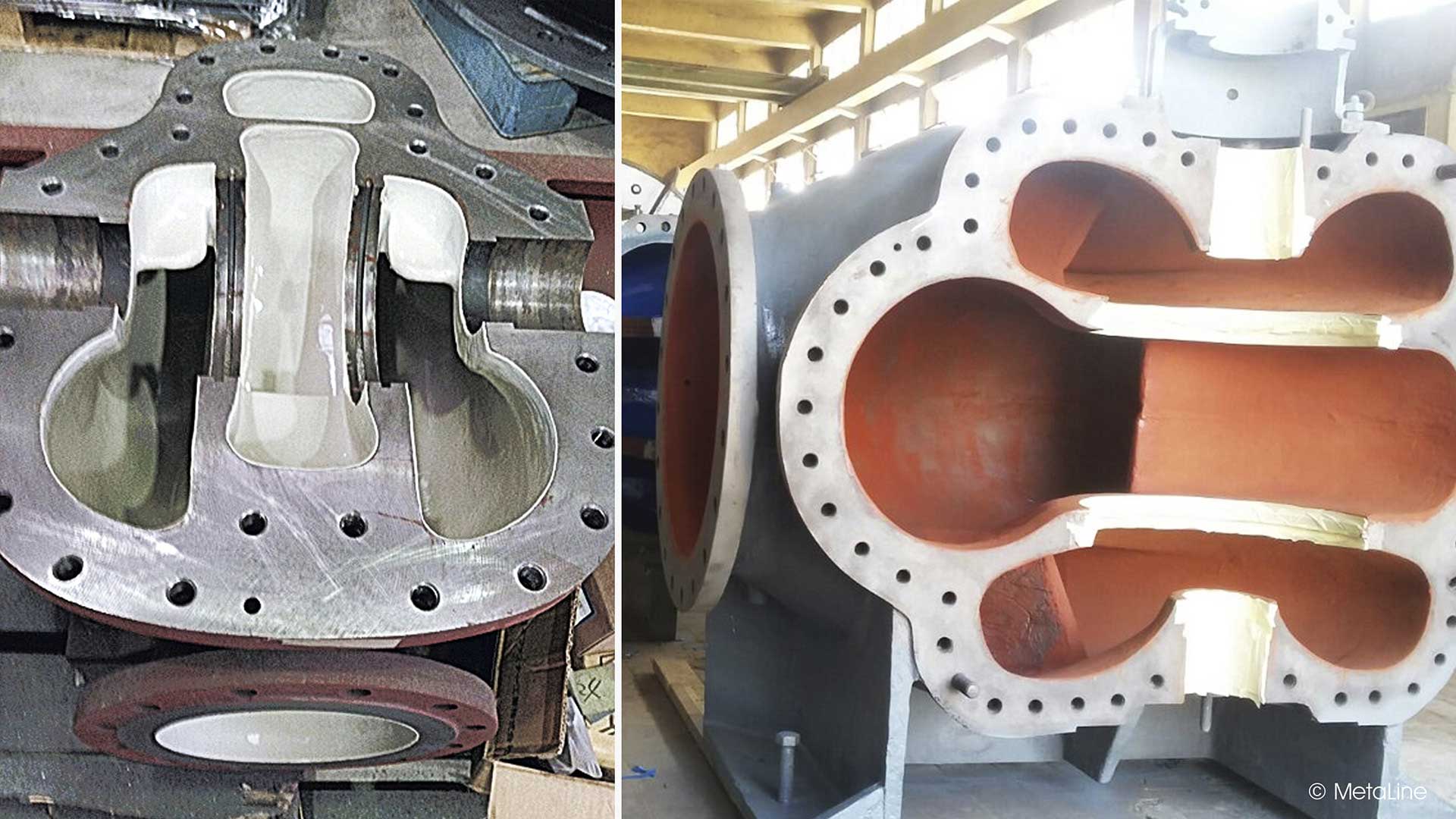

Pump coating - Our competitors are pure repair materials - here you can see real construction materials that can also be used retrospectively in a repair situation. More performance is not possible!

Pump coating - a technology made in Germany. MetaLine Series 700 wear protection coatings stand for maximum efficiency and functionality. You have a problem and are looking for the right solution - ask us! We have unusual solutions.

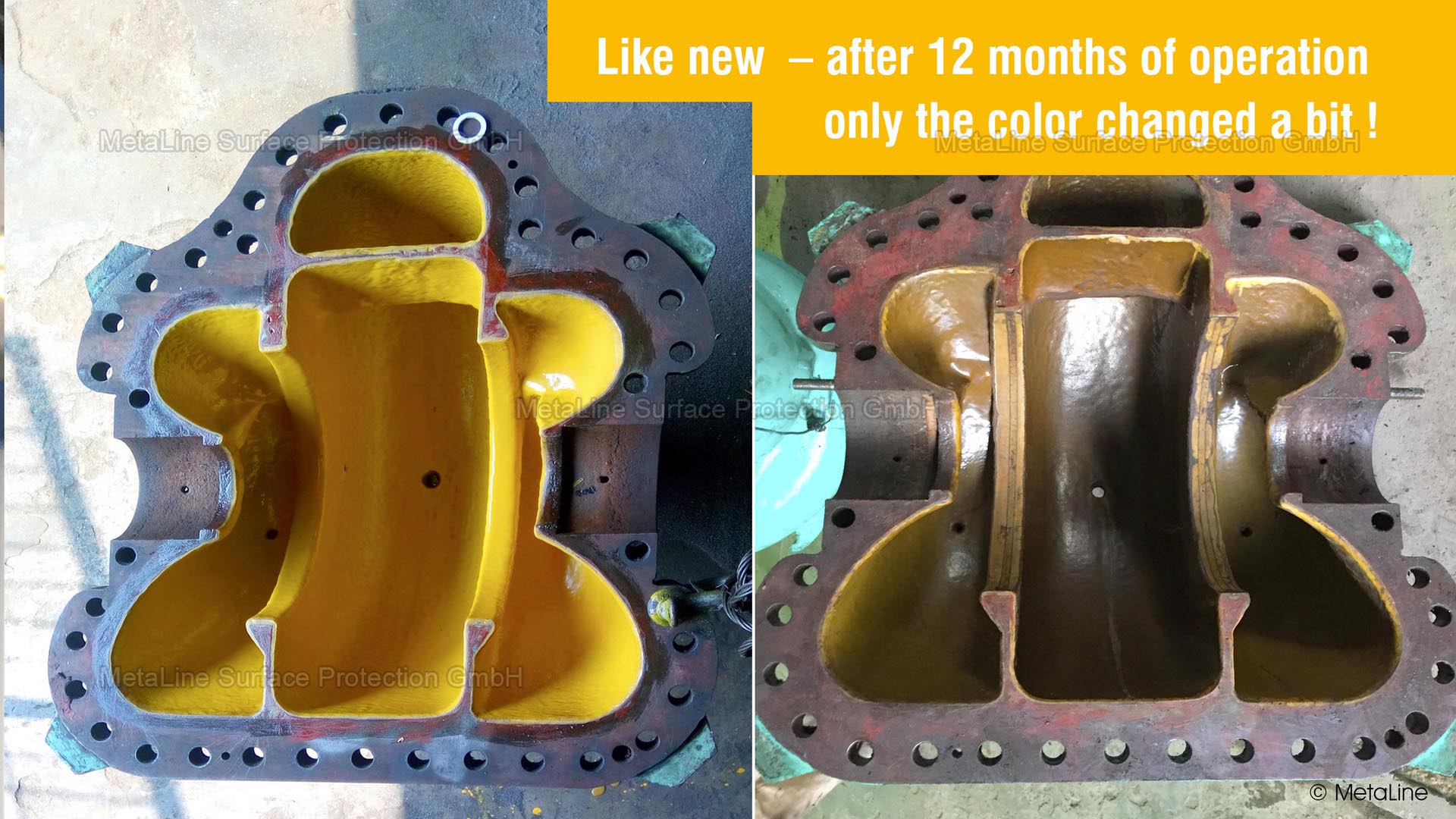

Pump protection - what a result! After 12 months of operation, there is not the slightest sign of wear on this pump volute coated with MetaLine 785. The color changes are of an optical nature and typical for elastomers. More "protection" is not possible!

Pump housing coating - a 4 mm (160 mils) layer of MetaLine 785 protects this pump housing of a municipal sewage treatment plant in southern Germany against wear and foreign object impact. Why so thick? Because they don't know what's being pumped through!

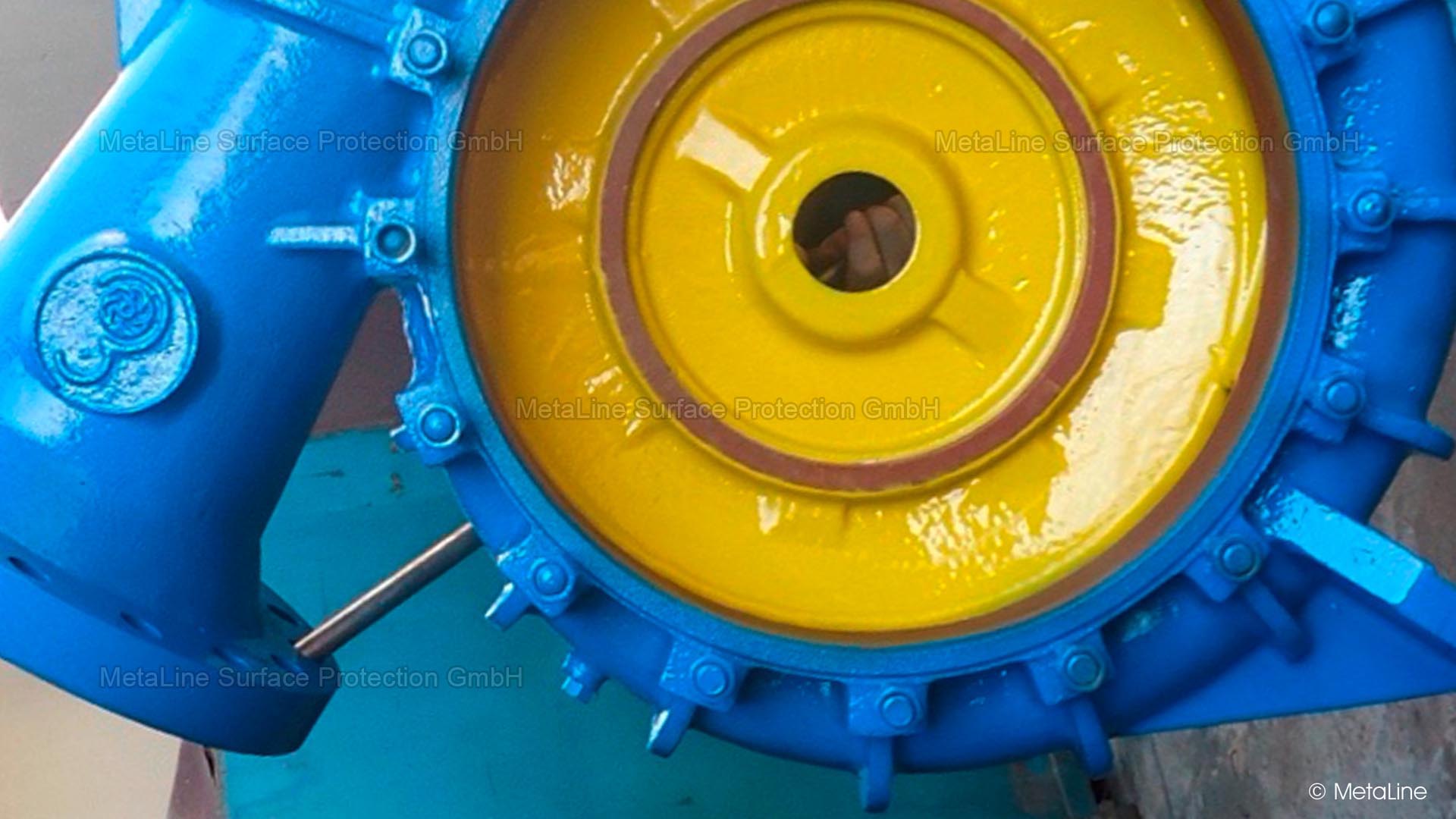

Pump refurbishment - MetaLine 785 on the impeller and housing of this pump. Steel that develops the same wear resistance as stainless steel thanks to our coating! Do you have any doubts? Ask us for the test reports of the pump manufacturers Andritz or KSB. Then you'll have it in black and white!

Pump lining - French pump housing coated on site with 5 mm (200 mils) MetaLine 785. The coating can come to the component - or the component can come to the coating! MetaLine has a portfolio that covers almost all technical requirements!

Pump lining - more durable than epoxy ceramics, smoother than epoxy ceramics, more economical than epoxy ceramics: MetaLine Series 700 - we are simply taking a different approach to pump protection coating thanks to its absorbent properties. The result is convincing!

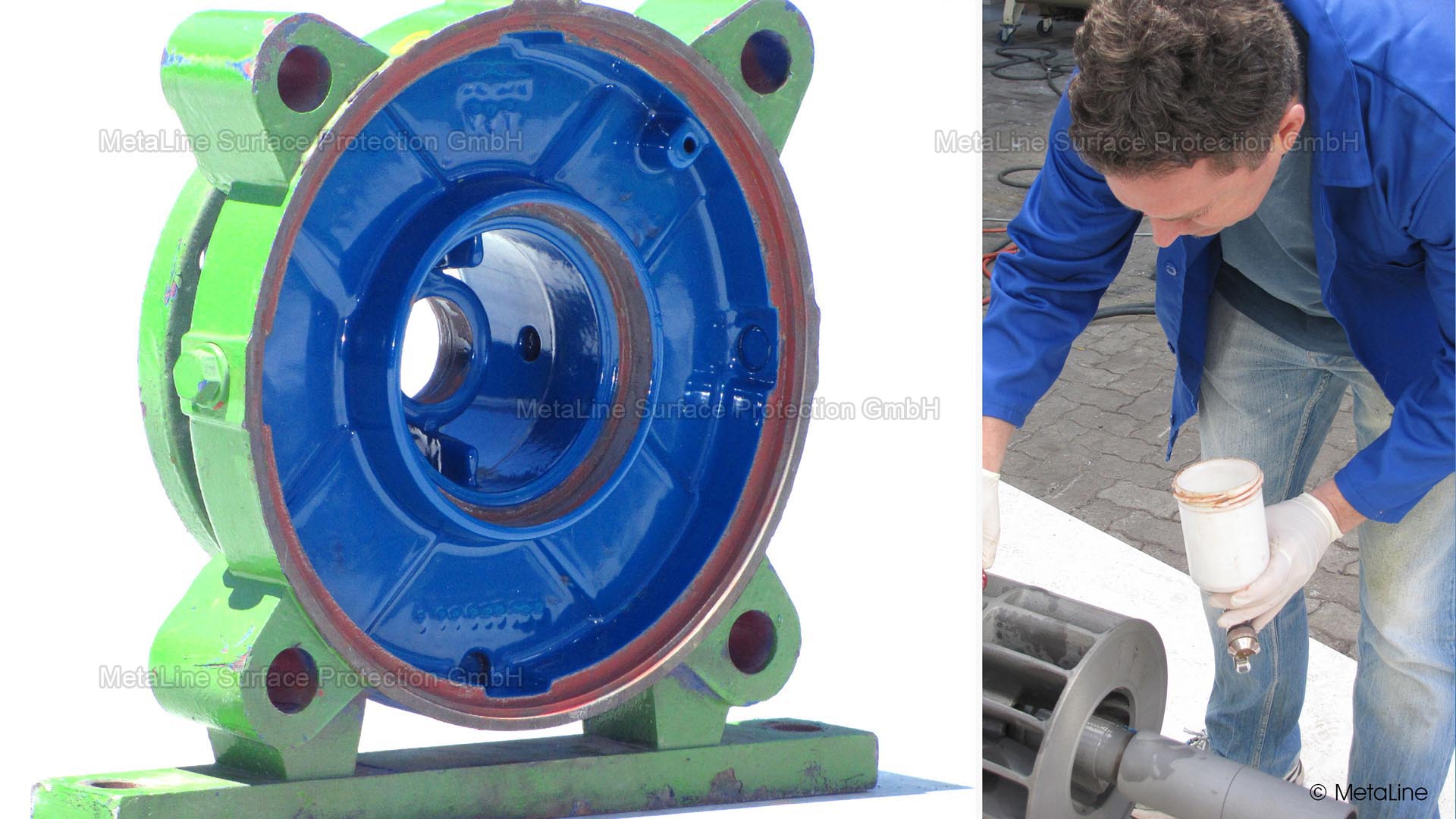

Pump protective lining - MetaLine 785 protects with a thickness of 2 mm (80 mils) on a series of huge cooling water pumps for power plants on the Yellow River in China. Those familiar with Asia will immediately recognize that the gentleman in the picture is Japanese and that the pumps therefore come from Japan. This is globalization - and MetaLine is right in the middle of it!

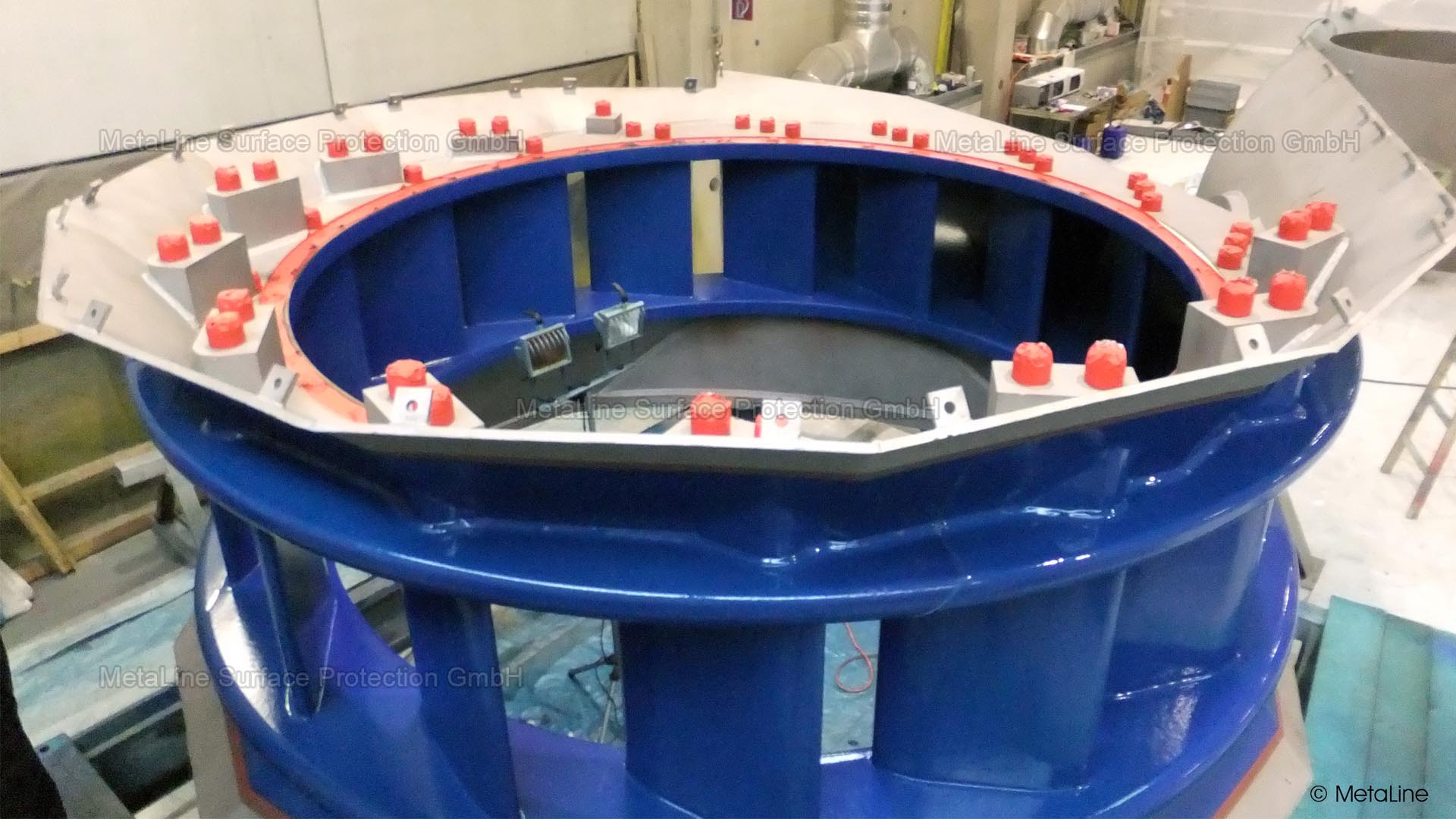

Pump protection concept - the wear-resistant properties of MetaLine 785 consistently implemented - all water-carrying parts are synthetically elastomerized and sustainably protected. A good approach for a long-term result

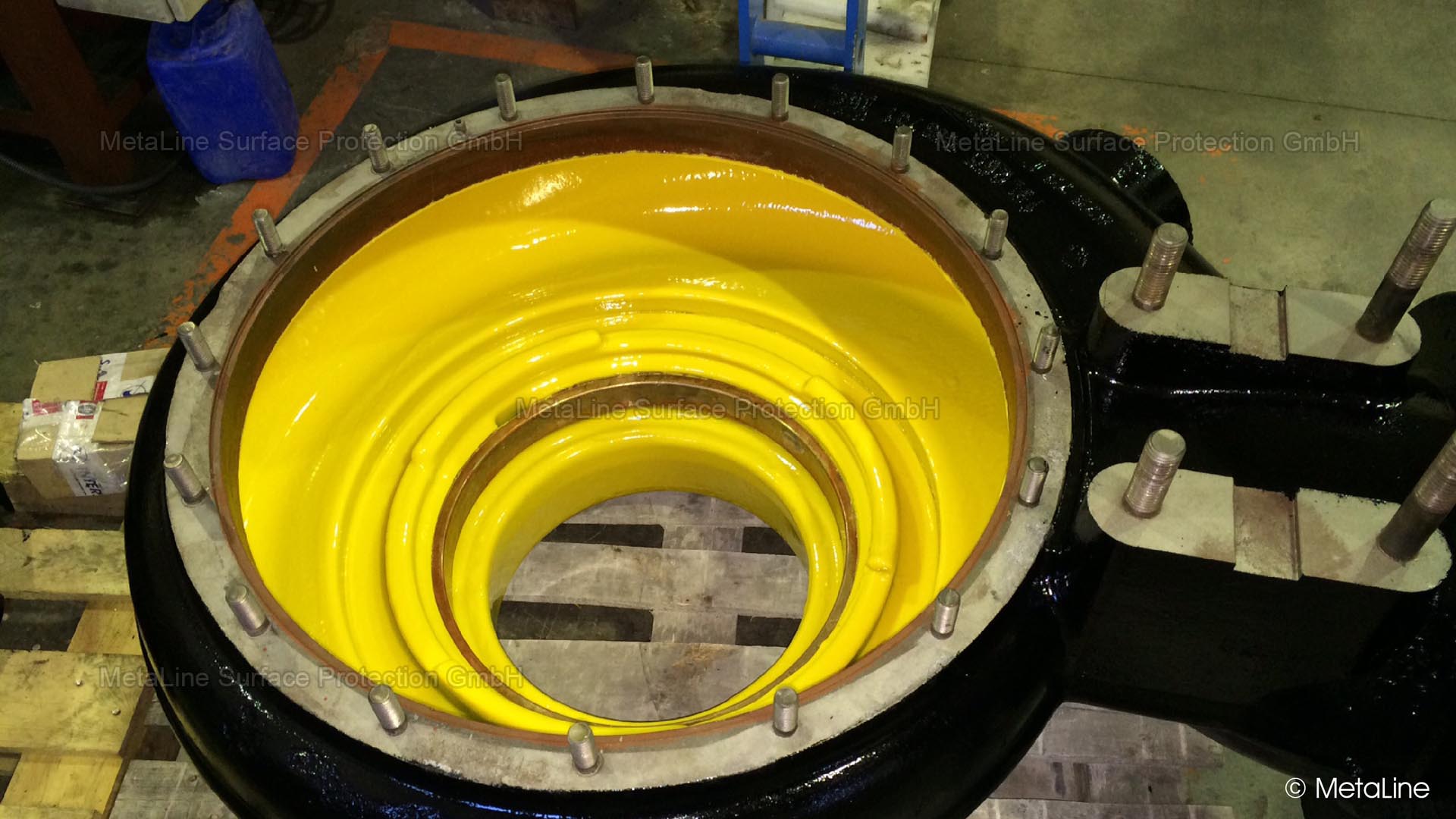

Pump casing coating – elastomeric lining with 3 mm (120 mils) MetaLine 785 inside this casing and impeller of the manufacturer Egger™. The tube shaped exit is characteristic for this pump construction. A tough work for any coating supplier. MetaLine made it...

Submersible pump coating - whether inside or outside, MetaLine elastomeric wear protection coatings from the 700 series protect your systems against mechanical and, in some cases, chemical attack. Pump rental companies in particular appreciate the repairability of our coating - so that the renter does not always have to be charged for a new impeller

Submersible pumps protective coating - why do many pump manufacturers deliver their housings WITHOUT a protective coating? Counter question: Why do all car manufacturers deliver their vehicles WITHOUT a stainless steel exhaust system? Have you recognized the logic? No manufacturer can survive without the spare parts business. MetaLine takes a different approach - as shown in this picture

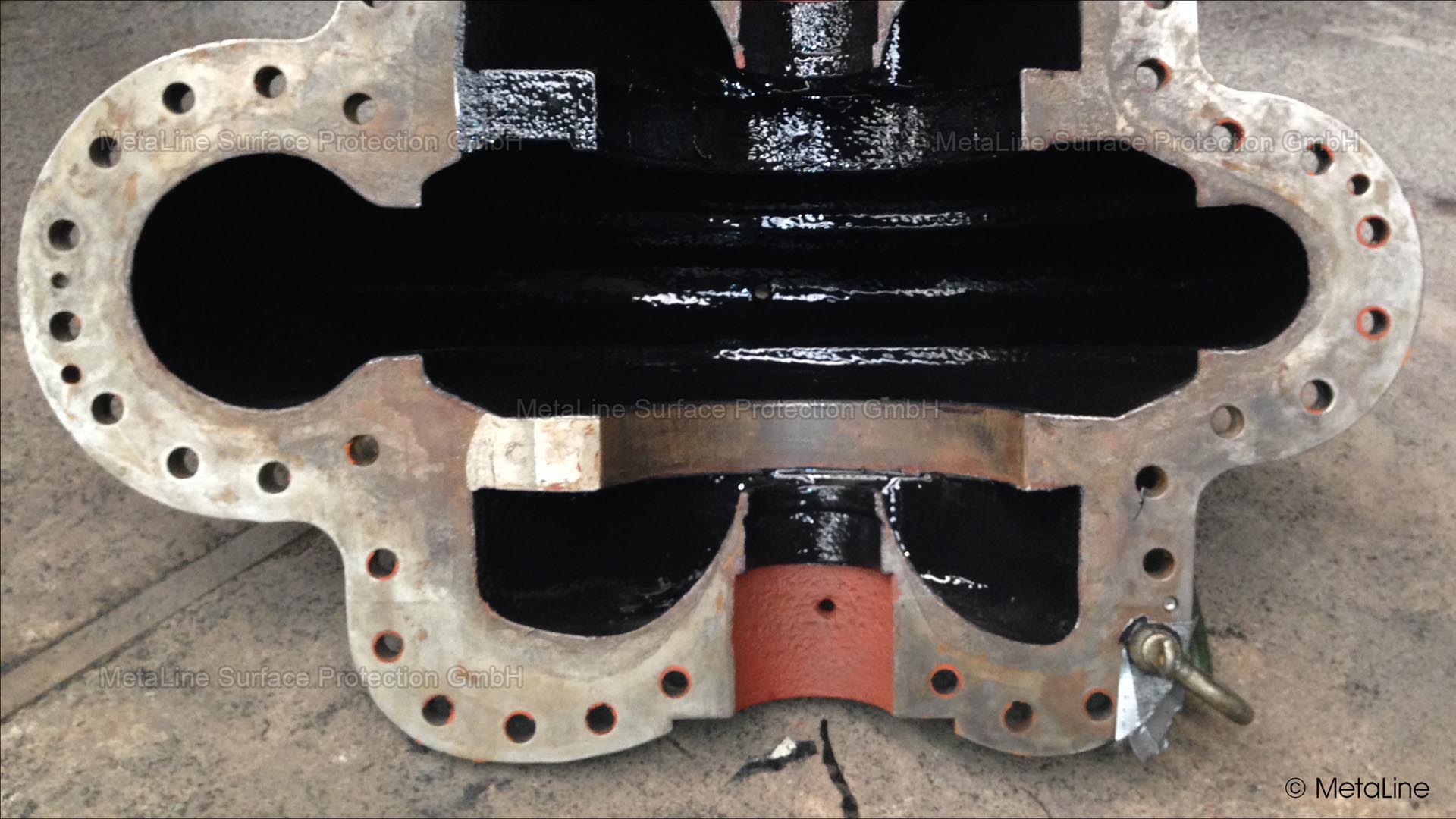

Pump wear protection - NEMO™ worm pump housing with internal protective coating of 4 mm (160 mils) MetaLine 785. You will find more than 1,250 application images on our website - and there are still people who claim that coatings don't work?

Pump spare part - half-shell made of rubber successfully reconditioned with MetaLine 785. As good as new, but significantly cheaper. Ecologically and economically, this rubber refurbishment with MetaLine is unbeatable, because you can't weld rubber either . . .

Semi-shell regeneration - a repair and recoating with MetaLine 785 brings this polyurethane pump spare part back to life. Identical service life with a significant reduction in repair costs compared to a new purchase. That is the strength of MetaLine . . .

Pump semi-shell repair - Please do not believe that the processing of MetaLine Series 700 is as easy as it may appear in these pictures - it is like any good technology! It also depends on the skill of the installer

Sludge pump coating - a pump lining regenerated with MetaLine 785 during assembly. Not only economically but also ecologically a proven method to optimize the use of components subject to heavy wear. You also become less dependent on spare parts delivery times

Pump half-shell repair - an extreme example of a successful recoating. But honestly! You shouldn't wait until there's nothing left to refurbish. You also go to the doctor before you die . . . Timely refurbishment saves effort and reduces the risk of failure

Polyurethane components - MetaLine as a genuine elastomer coating is not only suitable for use on metal, but is virtually predestined for the repair of rubber and polyurethane workpieces. Why? Because until now there was no repair method at all for these materials - only scrapping!

Pump optimization - coating precision in technical perfection. On this pump component, 1.5 mm (60 mils) MetaLine 795 ensures an increase in efficiency of approx. 3.5 %. Do you have any questions about this picture or this application? Simply take a screen shot and send it to us by email. We will get back to you!

Pump service life extension - there are many things that non-customers criticize about our technology: Too thick, too complex, too expensive! But just ask our buying customers who can really evaluate it! We would be happy to put you in touch with a reference!

Pump housing wear protection - 1.5 mm (60 mils) MetaLine 795 in a very complex housing geometry. Unbeatable in terms of uniformity thanks to our low-pressure spraying process. One of the biggest difficulties with spray coating is the right spray angle and the correct spray distance - WE get it right!

Pump lining - why do many pump manufacturers deliver their housings WITHOUT a protective coating? Counter question: Why do all car manufacturers deliver their vehicles WITHOUT a stainless steel exhaust system? Have you recognized the logic? No manufacturer can survive without the spare parts business

Pump coating - MetaLine 785 protects this Flygt™ pump housing and extends its service life. Elastomeric coatings can absorb significantly greater impact and shock loads than conventional rigid coatings, which are often brushed or trowel applied in this area

Increased efficiency - an elastomeric MetaLine protective coating has a significantly smoother surface than any metallic replacement part! Moreover, the surface quality and flow optimization cannot be achieved by any brushed epoxy ceramic material. It doesn't get any better than smooth!

Wear plate repair - Tolerances are a decisive criterion in mechanical engineering. But please understand that elastomeric (soft) surfaces must not be evaluated with metallic (hard) test methods and standards. The measuring instruments alone are completely different . . .

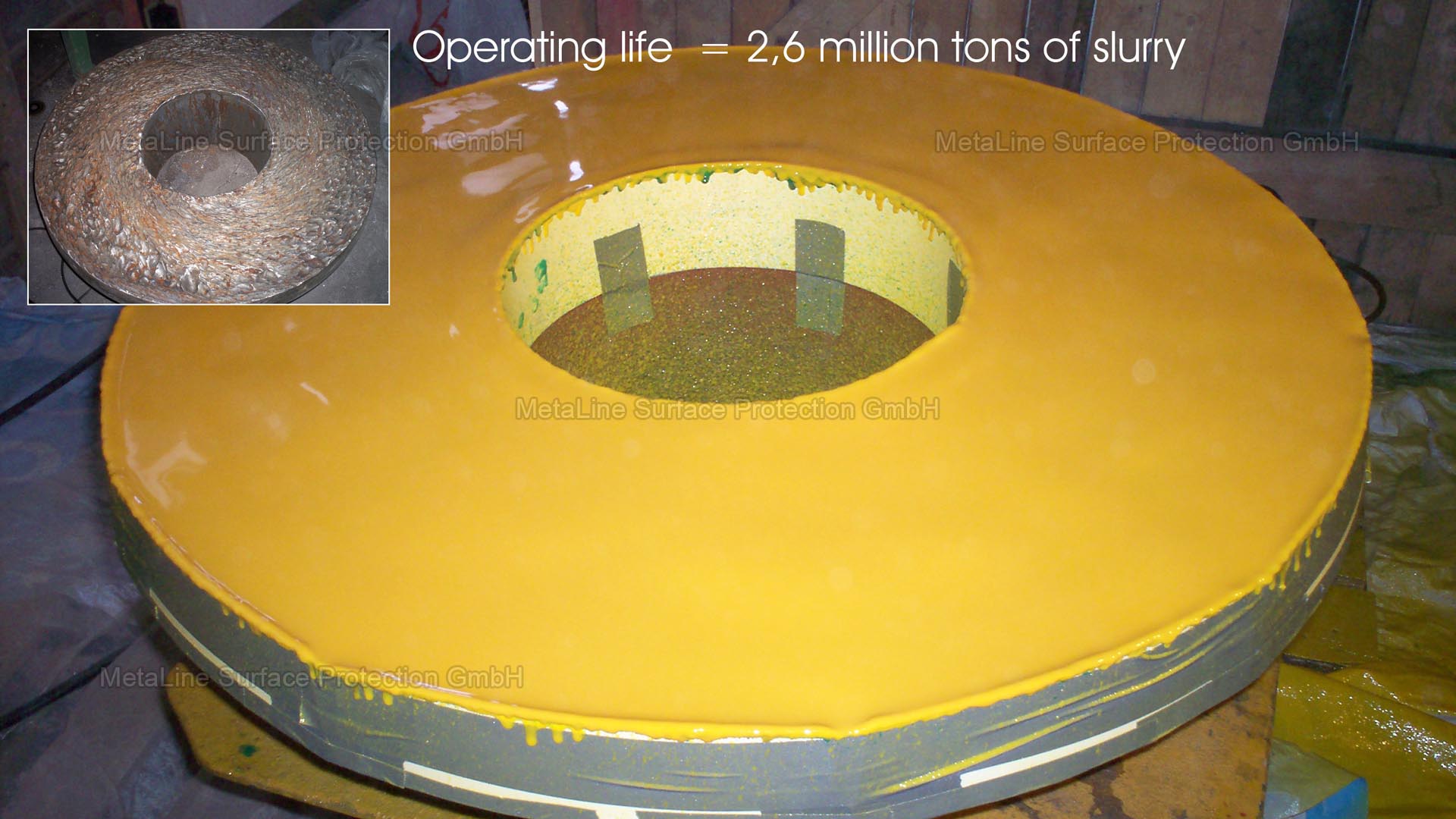

Wear plate coating – a remarkable life-time of 2,6 million tons of slurry – and still the one or other is not satisfied. But for a correct evaluation, the cost of the repair as well as of the spare part must be compared additionaly. Latest at this point, the overall cost benefit of MetaLine becomes obvious . . .

Wear protection coating - what is a good result for a pump coating? Not that the pump rotates for as long as possible, but that the largest possible quantity of liquid is transported during this time! In other words, the wear should be as stable and low as possible over the longest possible period. Ferrous metals behave in the opposite way here, because in addition to erosion there is also CORROSION!

Pump linings - there are dozens of coatings on the market! How can you find your way around? First of all, you can rule out all thermal coatings. With powder application, the coating thickness is always the same for all requirements - and that can't be right! Then exclude all brushed/filled coatings - your pump is not a garden fence. And read about the rest and let the (hopefully) large number of pictures sink in. We will hear from you!

Pump protection system - our mechanical wear protection (MetaLine 785 / gray) in combination with the electrochemically active corrosion protection (MetaLine 924 / red). You also have to deal with the uncoated border surfaces - otherwise there is a risk of corrosive infiltration from the edge. Different diseases require different drugs!

Pump protection coating - the umpteenth image of a wear protection measure with MetaLine. Still not convinced? Just call +49703431000 (GMT+1) and put your questions to Peter Schramm. He is the specialist with over 4 decades of personal experience . . .

Pump protective lining - there are those who fundamentally doubt the effectiveness of protective coatings in pumps. We don't want to go that far - but we are also of the opinion that the majority of brushable do-it-yourself materials are not a permanent technical solution. As is so often the case, it depends on the specialization of the supplier of these materials. Read more about this in the KSB pump coating test. See above!

Pump lining - if only everything were as easy as Internet providers would have you believe! No, coatings are something for specialists - whenever it is possible to do it yourself, we will support you. But we also say a clear "stop" when the level of difficulty becomes too high. A visit to our coating center in southern Germany will clear up many questions!

Pump optimization - Stone trap of a pump housing for biogas plants. 4 mm (160 mils) MetaLine 785 protects the steel from corrosion and material erosion. The minimum coating thickness of elastomeric coatings must be calculated - these are load-dependent. Failure to do so may result in total failure!

Pump repair - Changing surface properties in a targeted manner is a complex procedure. MetaLine is a partner of various well-known pump manufacturers for their OEM linings. MetaLine looks at the entire route and shows you the most promising way - not the fastest!

Pump optimization - MetaLine Series 700 coatings have a "memory effect". What does that mean? No tendency to detach from the substrate due to tension. Sounds very simple, but is completely untypical for rubber coatings, for example. Especially with pumps of this size, every technical detail counts - engineering made in Germany!

Pump coating - mine pump (slurry pump) with a 25 mm (1 inch) thick MetaLine 785 protective lining. The wear resistance of different pump coatings must be compared using dynamic test methods - ask for them! In our competition you will only get linear abrasion values according to Taber - unfortunately these are the wrong ones!

Pump wear protection - one of the largest pump housings ever treated with MetaLine Series 700. Quite an unusual pump design for a Chinese pumped storage power plant. Why don't we want to brush or trowel pump housings? Because we have respect for the hydrodynamic efficiency and the desired low-turbulence flow conformity!

Pump coating - the exceptional durability of our MetaLine 785 elastomer armor is difficult for many to comprehend! How can a soft material structure be so much more durable than steel, stainless steel and especially the many expensive epoxy-ceramic materials available on the market? You have now seen over 40 different sample images on this single page alone! Now you should see for yourself!