Impeller repair - before and after! Our competition is brushed or troweled repair materials - still partially visible in the picture on the left. On the right you can see our construction materials, which can also be used afterwards in a repair situation. More quality is not possible!

Pump impeller repair - Coatings are not just simple technical processes, they also require experience at one point or another! That's why we can advise you on whether in-house processing really makes sense for your application

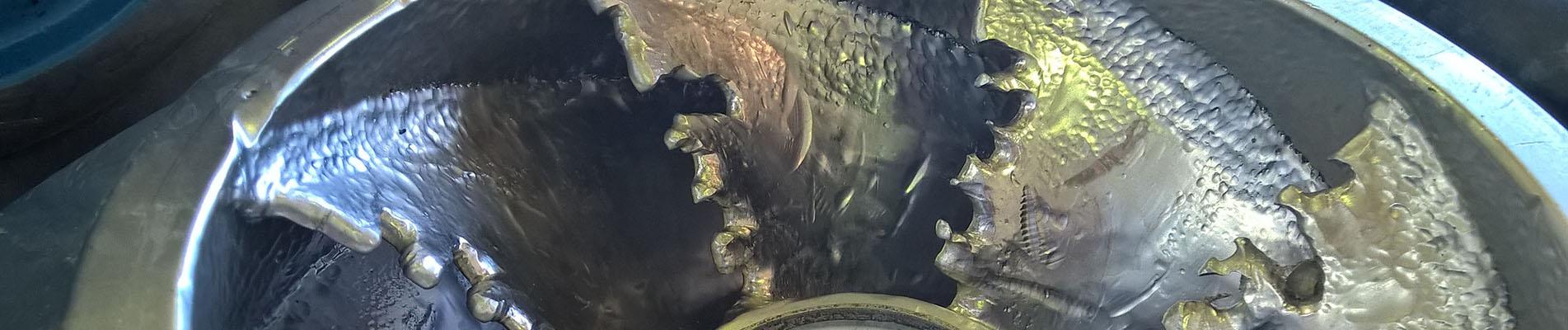

Impeller repair - particularly severe cavitations on the impeller of a "water brake" - the stability limit has been reached and further testing of the statics is absolutely necessary

Pump impeller overhaul - in this case not with our elastomeric coating technology Series 700, but with MetaLine repair ceramic SXL / KXL due to the severe structural damage. The choice of material is the first mistake you can make . . .

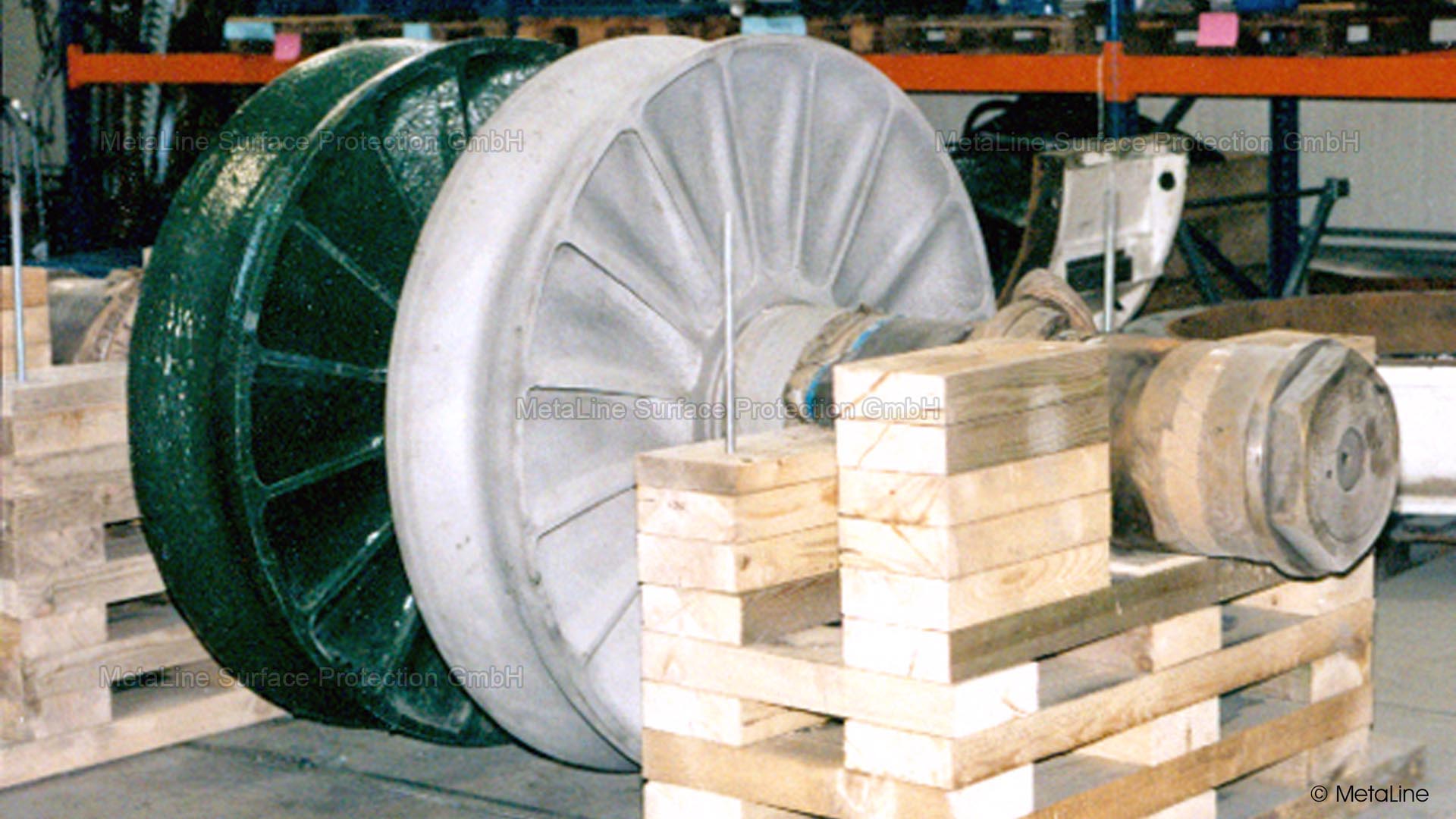

Impeller protection - the left side has a protective coating. No coating is required on the right-hand side due to the lower load. These are considerable dimensions weighing several tons. You have a problem and are looking for the right solution - just ask us

Impeller repair - damaged solid rubber pump impeller with a torn out vane - usually a case for scrap. This process is suitable for repairing damage caused by accidents. However, it is not suitable for reinforcing the strength of permanently overloaded components!

Impeller overhaul - during recontouring of the missing blade using the casting process with MetaLine 760. The formwork was bent from 0.5 mm copper sheet. Do you have any questions about this picture or this application? Simply take a screen shot and send it to us by email. We will get back to you!

Impeller regeneration - the missing blade was reshaped and the entire impeller was additionally coated with MetaLine 785. The most complex part is the pre-treatment of the rubber as sandblasting is not technically possible. We use particularly small copper carbide tools for this purpose

Pump impeller regeneration - what distinguishes our repair materials from others on the market is the fact that we also process these materials for you or at least provide you with practical support in their application. A good approach for a good solution!

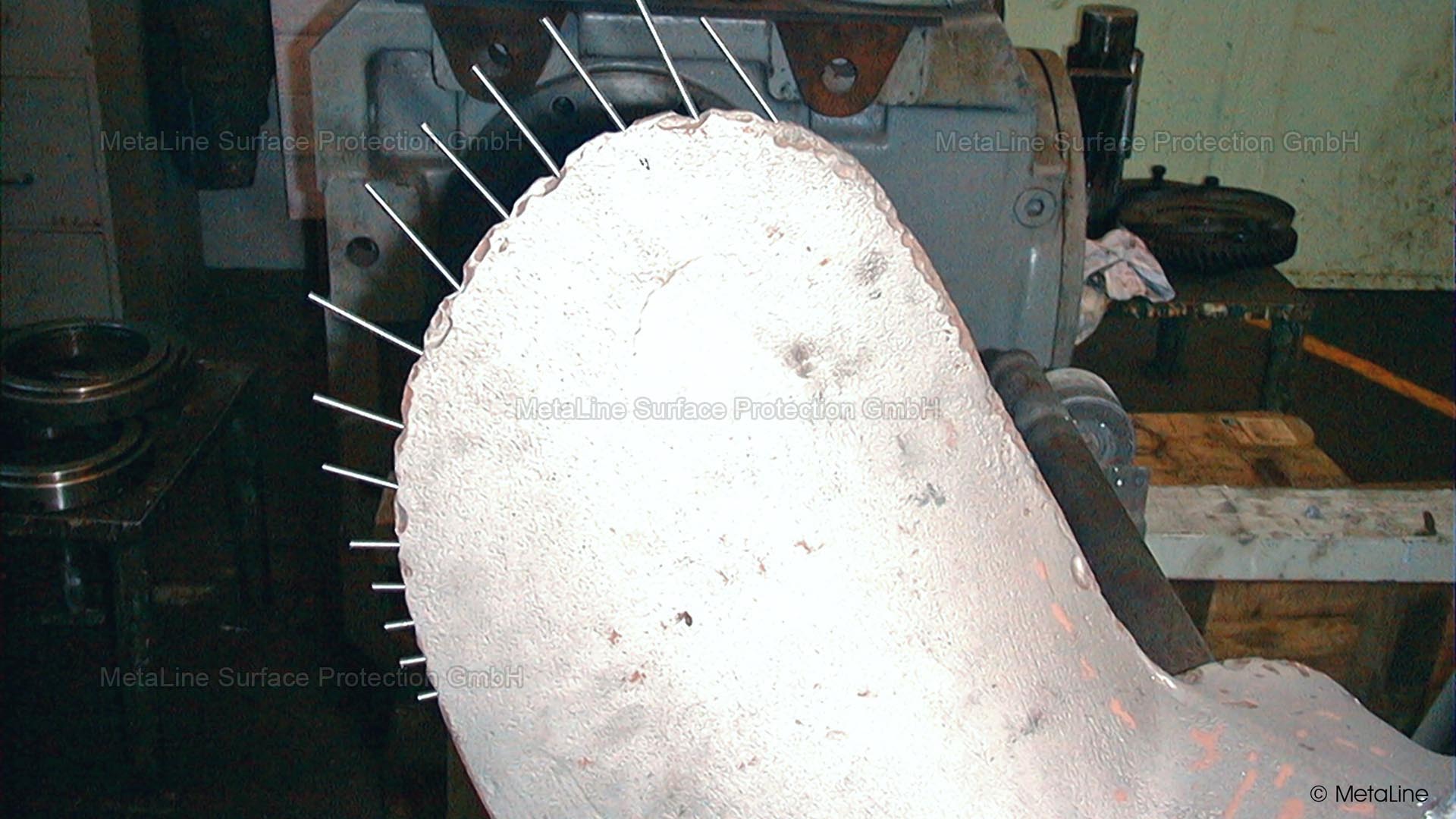

Rotor refurbishment - the edges were further machined, drilled and pinned. The entire surface was then sandblasted. An application at the absolute limits of physics - perhaps even a step beyond . . .

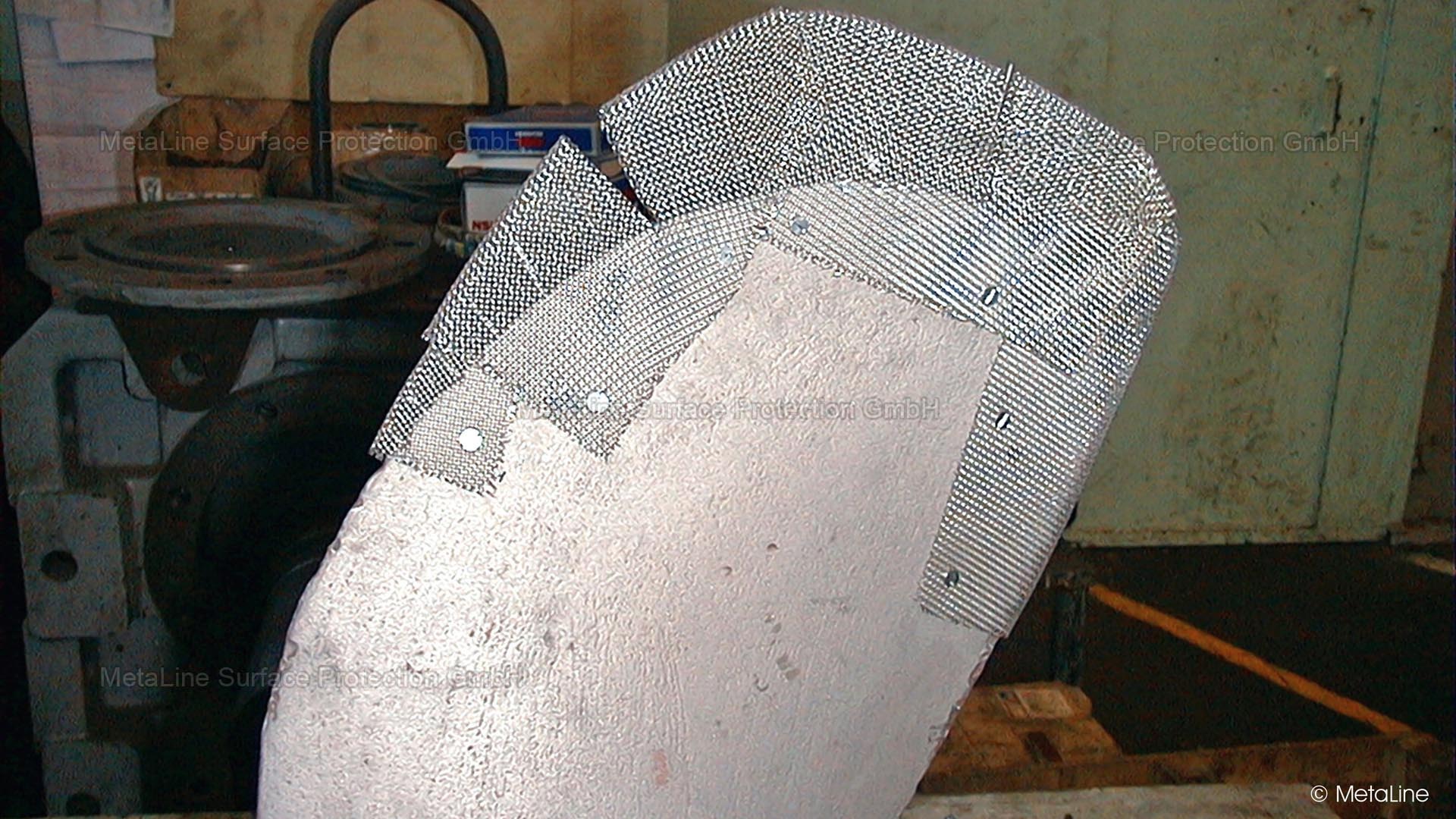

Rotor repair - the new contour was pre-marked using a metallic (ferrite-free) fabric reinforcement. Such a procedure only makes sense in the event of a shortage of spare parts or emergencies. The time required is considerable. Above all, the centrifugal loads must be calculated beforehand. Otherwise, "simply repairing" becomes a safety risk!

Rotor protection - a blade recontoured with MetaLine repair ceramic CXL. And if you're now saying with enthusiasm, I want to do that: Then give us a call so that we can talk you out of it! Why? Every case is different and needs to be analyzed - only on the Internet does everything look so simple!