Rudder coating – MetaLine 785 being used as high-end cavitation resistant coating for the most troublesome rudder belonging to a big container ship (10,500 TEU)

Francisturbinecoating – 2 mm MetaLine 785 protects this runner at the most impacted areas as a so-called softcoating system

Cavitation protection – MetaLine 785 is used as OEM-serial coating on BWT-reactors for the treatment of ballast water by use of cavitation forces

Tunnel thruster coating - electrochemical corrosion, cavitation, erosion. A dangerous mixture based on an energetic overload of the steel structure. The energy absorbing MetaLine 785 is the physically correct solution to cope with the situation.

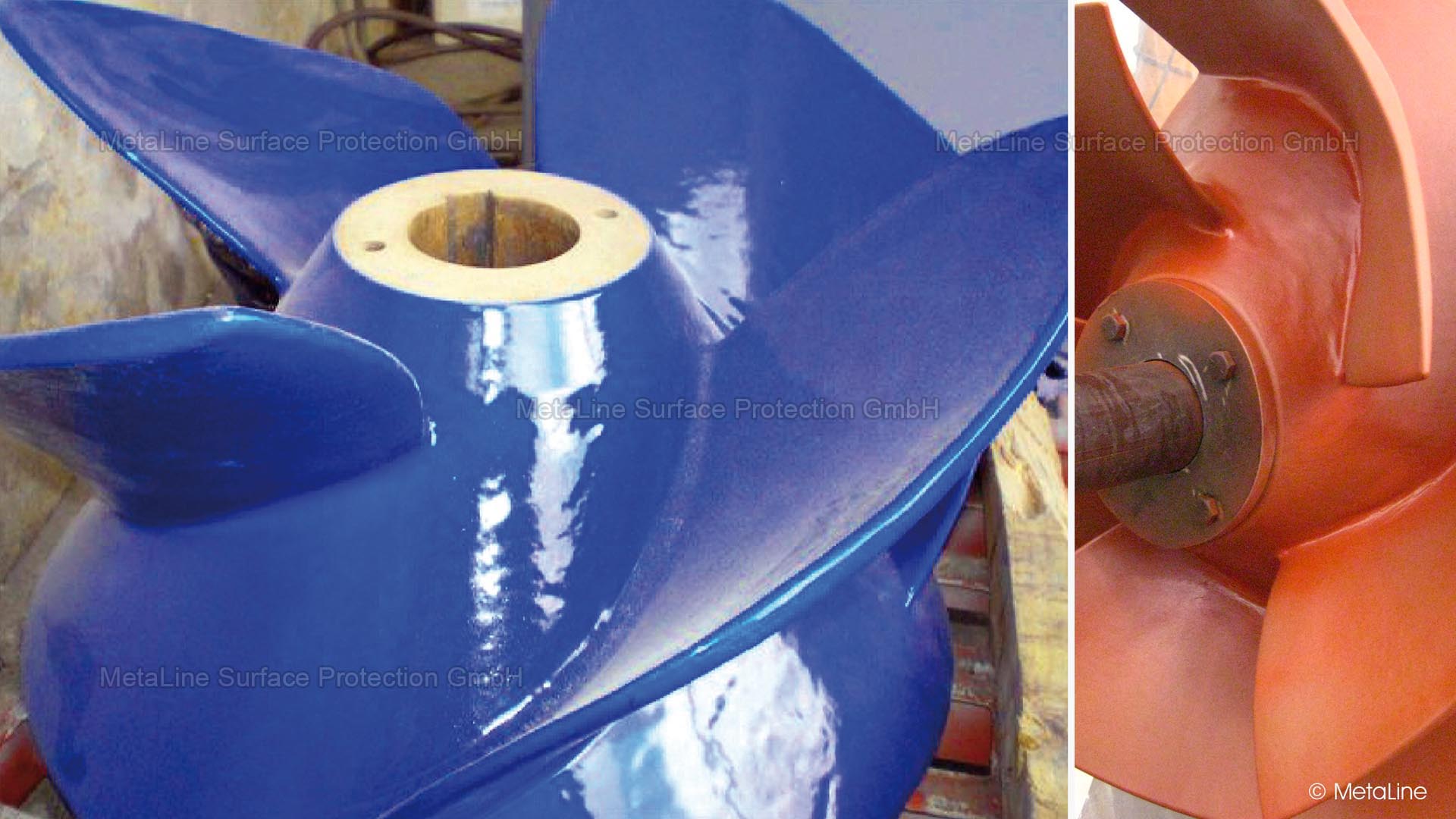

MetaLine 785 being used on alumina ship propellers for long-term protection against salt-water oxydation and cavitation

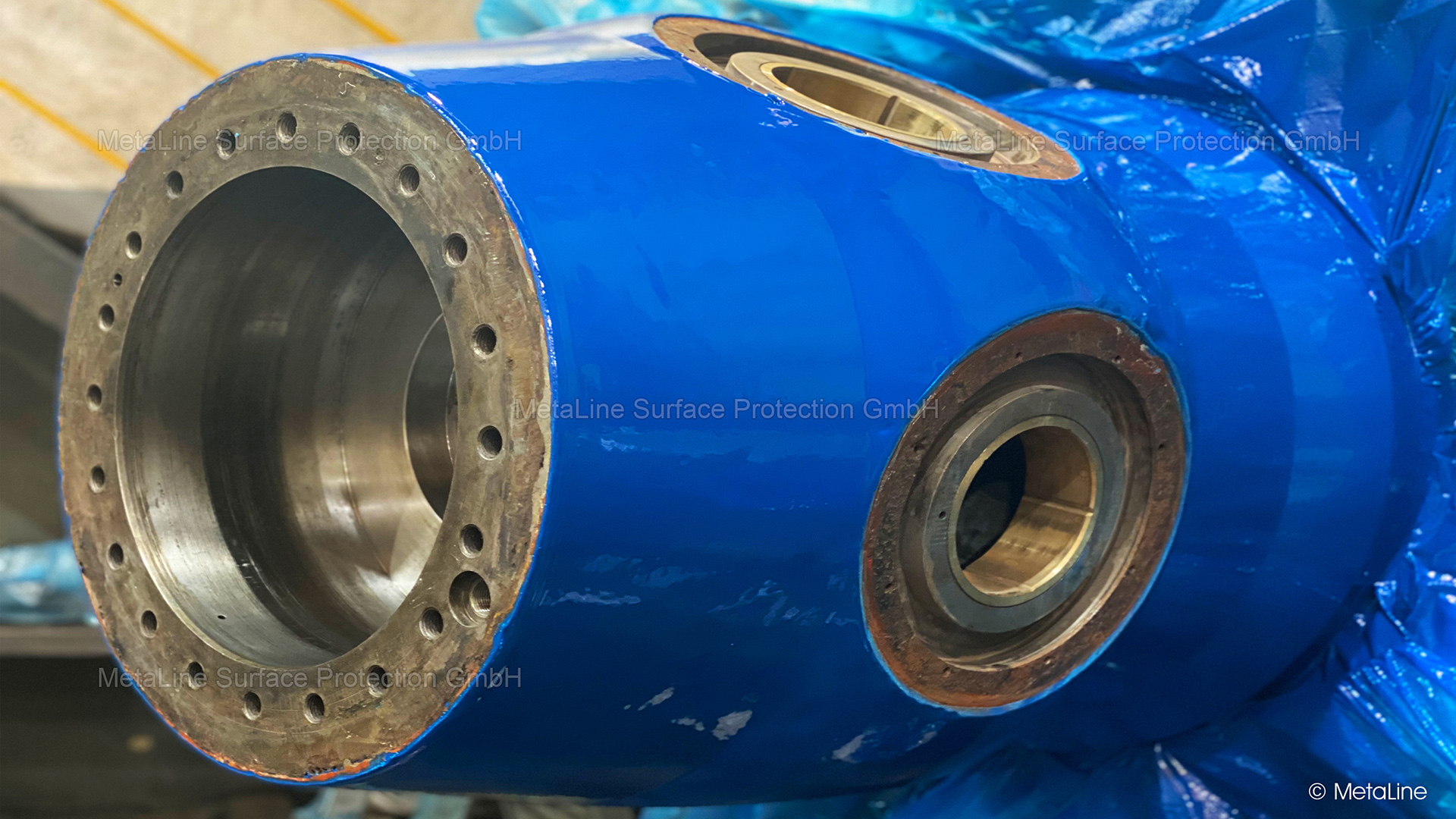

Stevencoating – a sprayable heavy duty cavitation protection for the durable treatment of this steven

Cooling water systems, mainly at coastal sites, require special protective systems – MetaLine Series 700 provide detailed solutions for many applications

Shut-off valve coated with MetaLine 785 – permanent protection against solid impact and corrosion

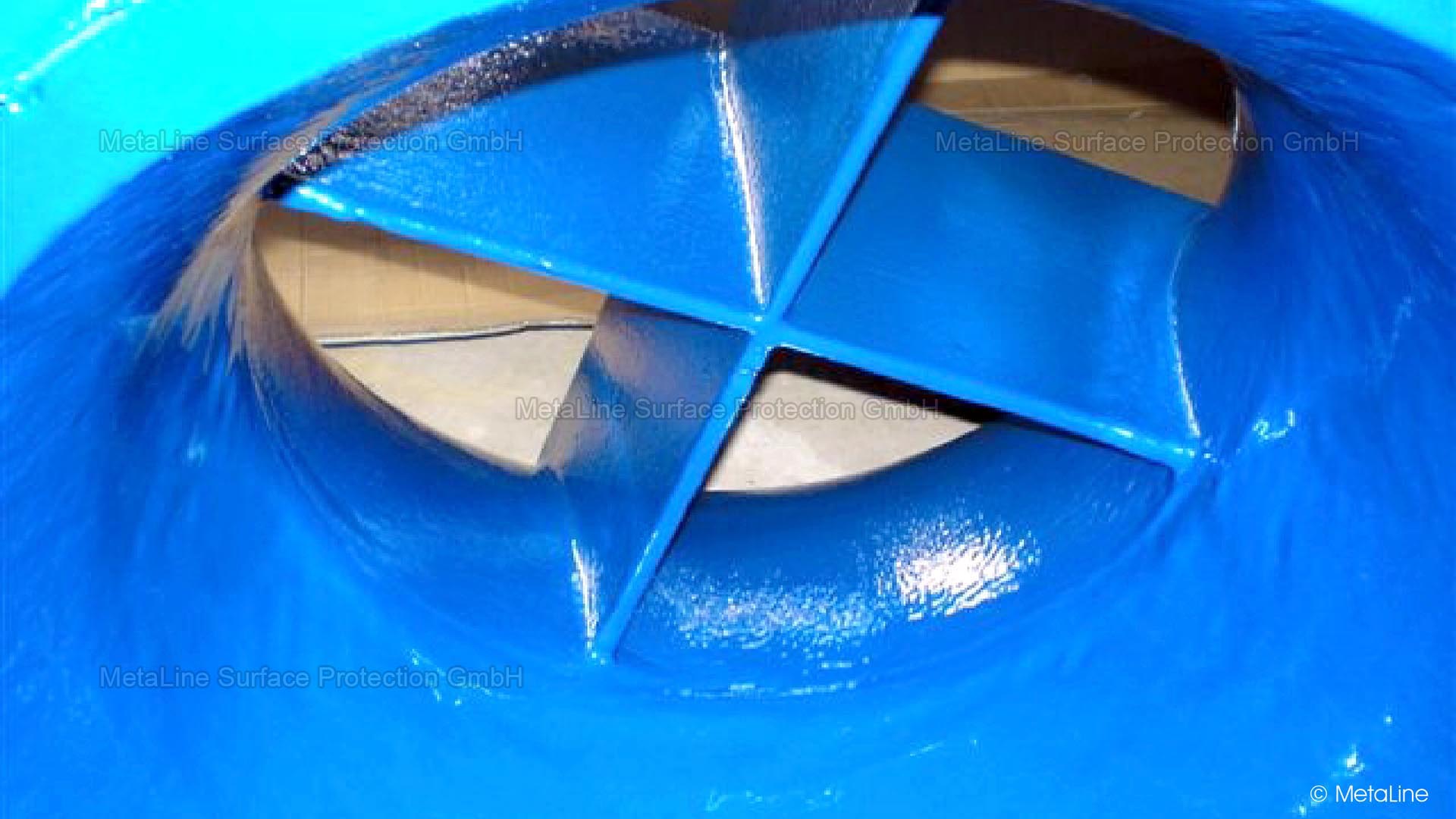

Francis impeller of a small hydroelectric power plant near the German river Inn coated with MetaLine – especially difficult to carry out due to the small blade distance

Quite unusual and not due to the book – a Francis impeller coated partially with MetaLine 785 in place without removing it

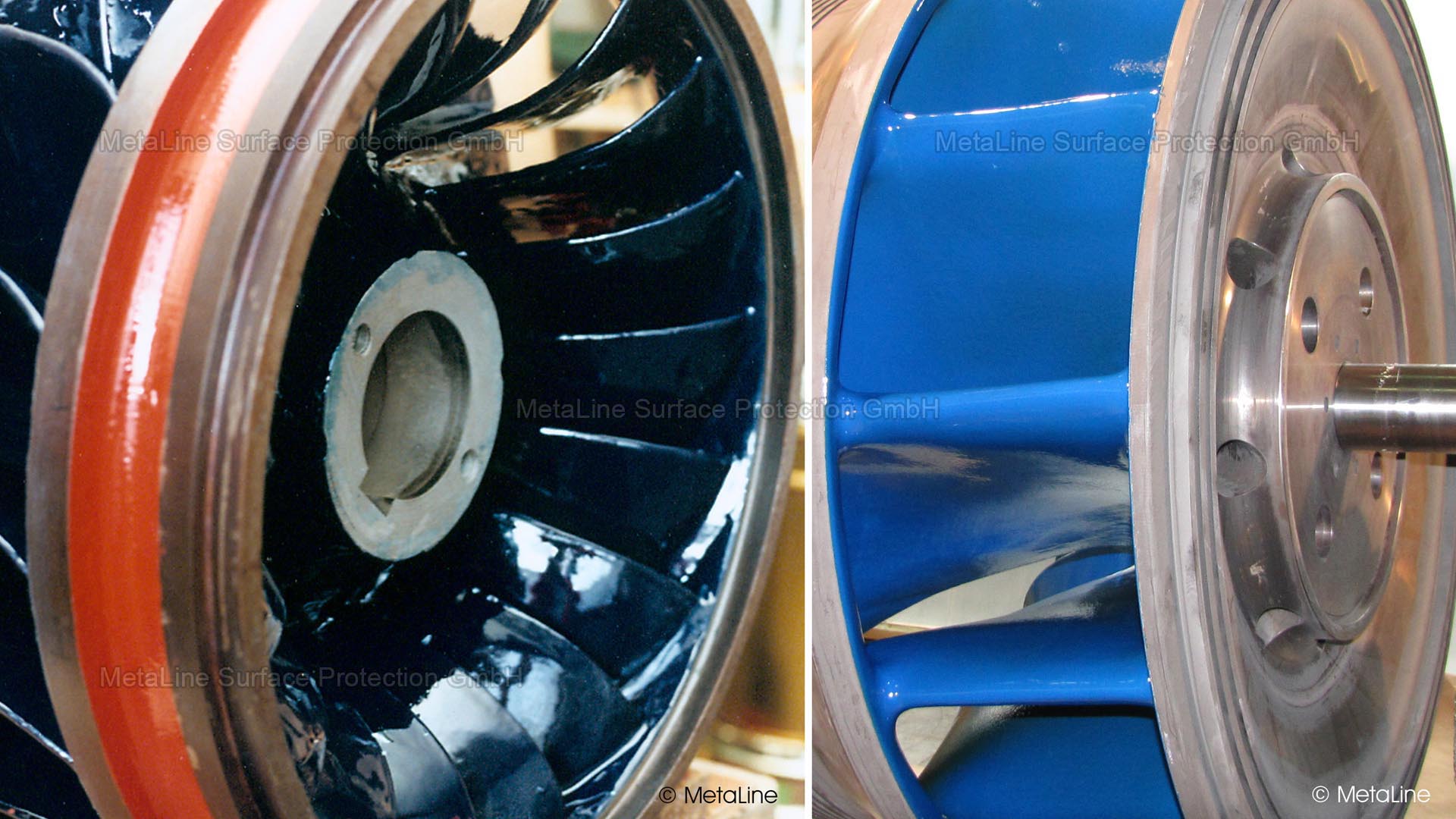

Francis impeller coating - what matters? A smooth and uniform surface, vibration resistance, impact-resistant rubber-like properties, tremendous adhesion, expertise - ask for MetaLine 785, because your impeller deserves no less!

Francis turbine coating – MetaLine 785 protects this big turbine impeller. The coating was applied directly for the turbine manufacturer as OEM supplier. Smoothness and fluid flow characteristics are impressive

Kaplan coating - Kaplan turbine runner coated with MetaLine 590 from a French power plant on the Lower Rhine. The MetaLine coatings are always also repairable just in case

Designed for special applications – 2,5 mm MetaLine 785 as professional – lightweight – cavitation protection

Pump component of a drinking water supply in Lisbon – coated with 2 mm MetaLine Series 700

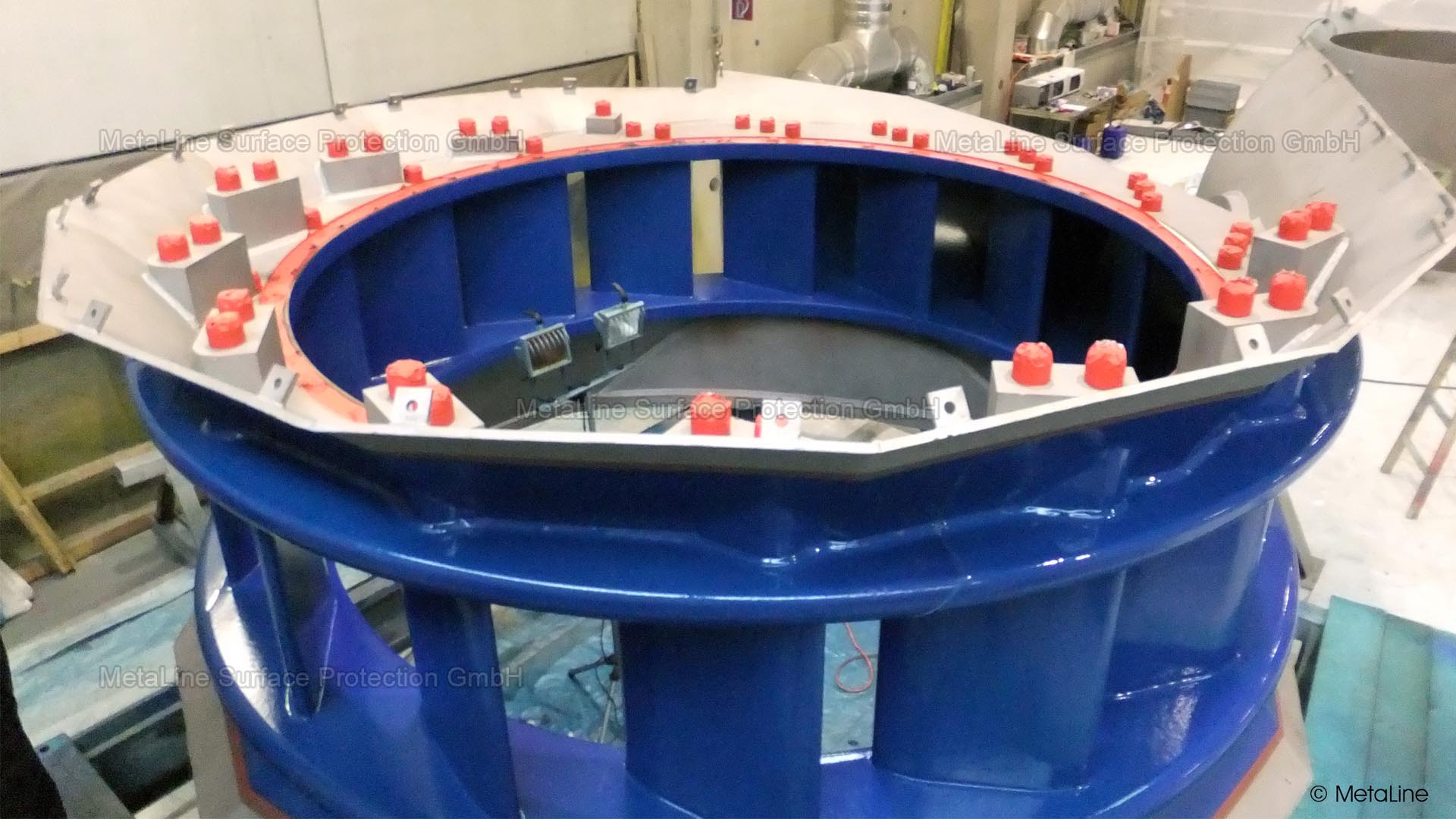

Turbine apparatus in a pump storage power station in Luxembourg coated with MetaLine Series 700

Hydroturbine coating - water inlet spiral of a Francis turbine in the area of the Swiss Gotthard massif coated with 2.5 mm MetaLine 785. Annual inspection reports since 2006 are available

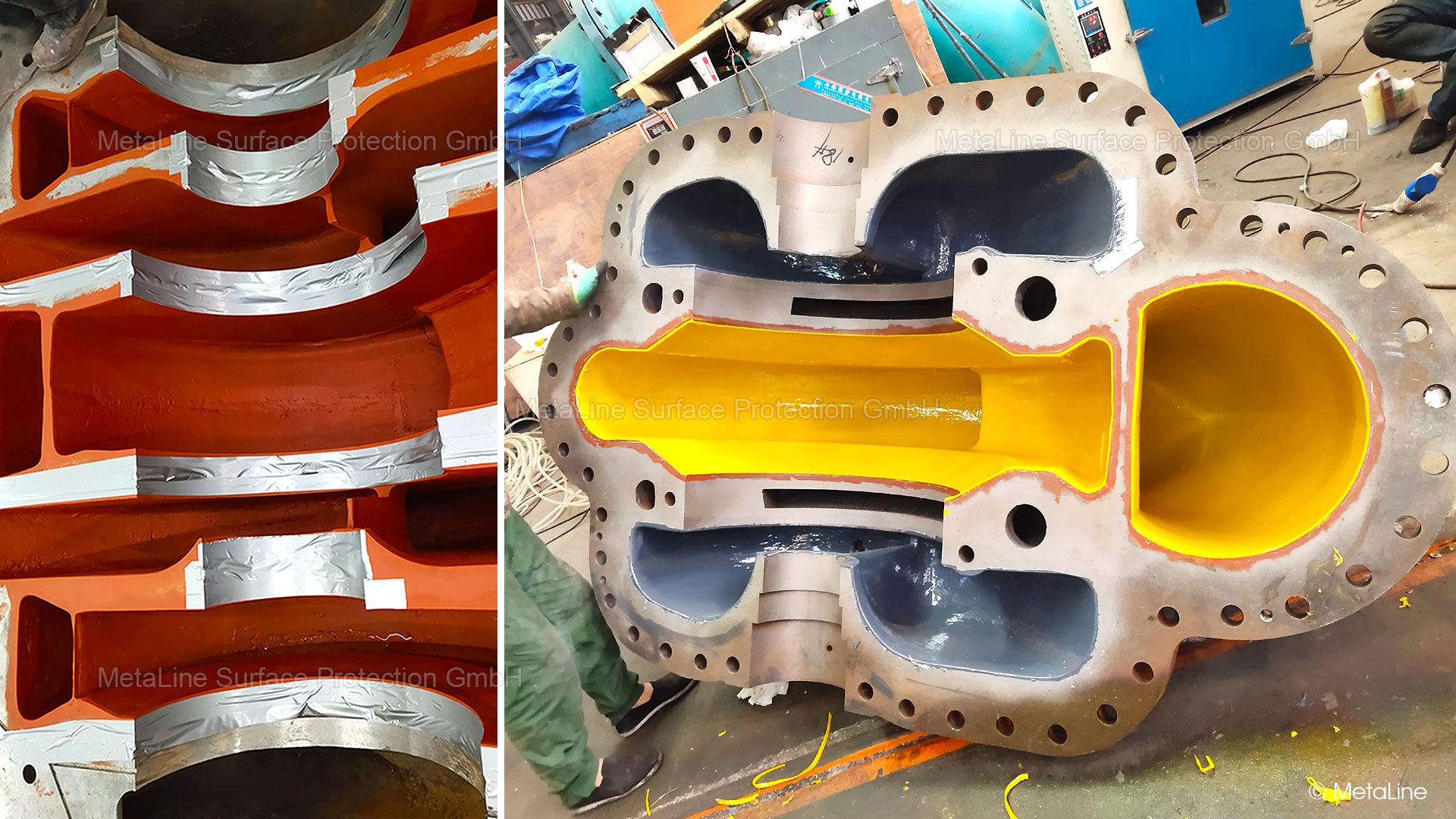

Pump casing protection – one of the biggest pump casings every coated with MetaLine Series 700. It is an unusual welding construction designed for a chinese hydro pumping station

Blade coating – MetaLine 785 had been applied completely smooth in a thickness of about 1,5 mm to these ventilator blades. Means the alumina-construction is perfectly protected against wear & tear

A coating with 4 mm MetaLine 785 helps the operator of this Portuguese Power Plant sleep better at night

Axially split pump housing coated with 2.5 mm MetaLine 785. Application site "yellow river in China". Under "Service/Company/References" you will find pictures of the casing after 4 years in operation - you will be surprised!

Vertical Kaplan turbine coating - an unusual case because the customer had coated the runner and the casing elastomerically. In total, 3 identical turbines were treated very successfully at a dam stage in France.

Blade support of a vertical Kaplan turbine - massive wear of up to 5 mm was recontoured with MetaLine 785 and the entire hood was given a protective coating. The cavitative attack at this plant in northern Spain is simply too high for unprotected operation.

Horizontal Kaplan turbine pipe coating - You would like to have more information about this application and the customer experience? Please contact us by phone and we will discuss. But please understand that we do not put customer data freely available on the Internet. Thank you!