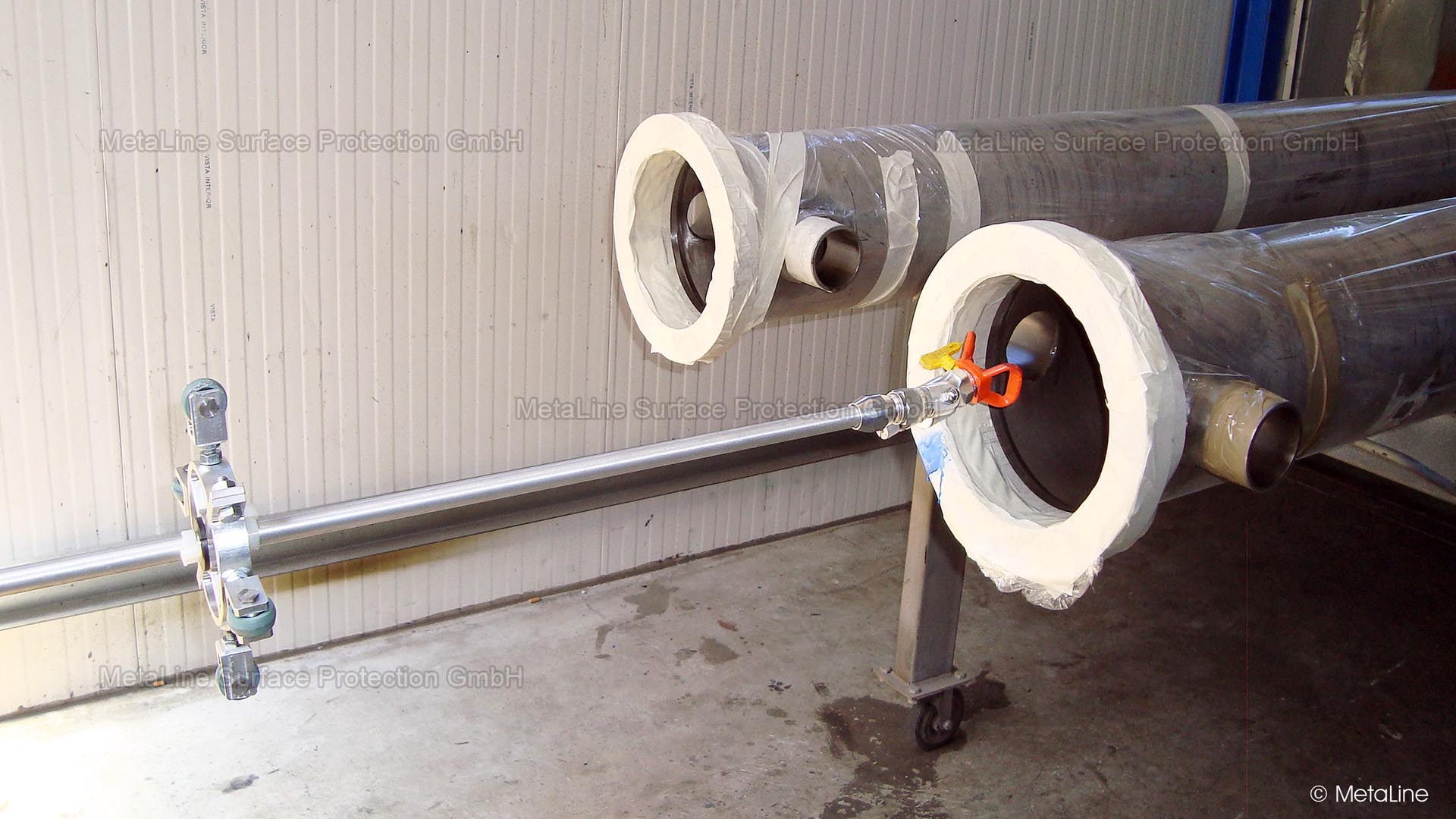

Internal pipe lining - MetaLine internal pipe coatings are feasible with the “Series 500” starting from a pipe diameter of 50 mm (2 inch). But please do NOT think about trying to realize this yourself with on-board equipment - that would be naive!

Pipe elbow protective coating - MetaLine 785 can be applied to practically any contour - convex, concave or curved - without tension or seams thanks to its liquid application. Vulcanized rubber requires a large number of seams to do so!

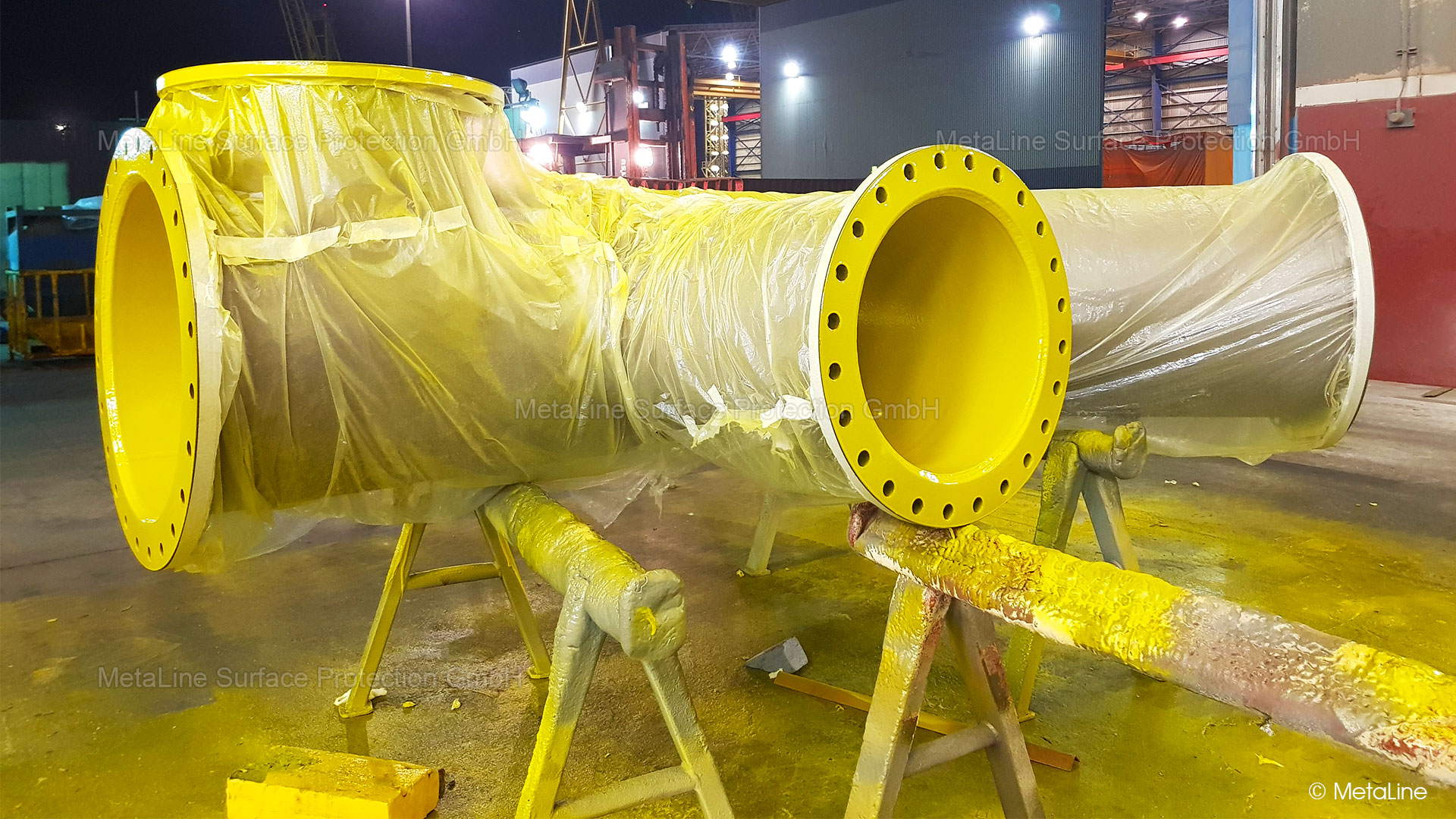

Pipe lagging - Please don't make the same mistake as this customer! The MetaLine 785 coating of a seawater pipe in the dry dock - in the color “black”. Internal coatings must have a “light” color so that the workman can control his work and quality in the best possible way!

Seawater piping repair - coating with MetaLine 785 replaces the time-consuming and often unavailable vulcanization in dry dock. No quality compromises as is the case when using a brittle epoxy ceramic. Soft rubber should not be replaced by hard epoxy!

Seawater-resistant rubber coating - MetaLine 785 is a cold applied, seamless synthetic spray-on "rubber" coating. Vulcanization is no longer required. The difference is the reduced layer thickness, a better coefficient of sliding friction and the seamless, flow-optimized transition to the flanges

Repair coating - everything can be coated. The only question is whether it makes sense? MetaLine takes on many challenges! But you won't find us trying to persuade you to undergo a pointless repair when a replacement part is more viable!

Corrosion protection coating - problem solutions usually require a technical dialog - this is not always easy or quick! But it is effective! Please do not shy away from this dialog - the decision will always be yours! And you can see the result of this dialog here in perfection . . .

Corrosion protection lining - looks like paint, but is a protective skin “that plays in a different league”! Erosion and cavitation-resistant, impact-resistant, permeation-inhibiting. Not cheap and easy, but durable and reliable!

Pipeline corrosion protection - if your anti-corrosion work shows less cleanliness and attention to detail, you should call us! Our products bring an “Engineering made in Germany” to your construction site, which is world-famous!

Internal pipe coating - is an elastomeric internal lining of ballast water pipes really necessary? No, in many cases not! However, if increased functional safety is required - such as on LNG tankers - then all the technical arguments speak in favor of “spray rubber coating” with MetaLine 785!

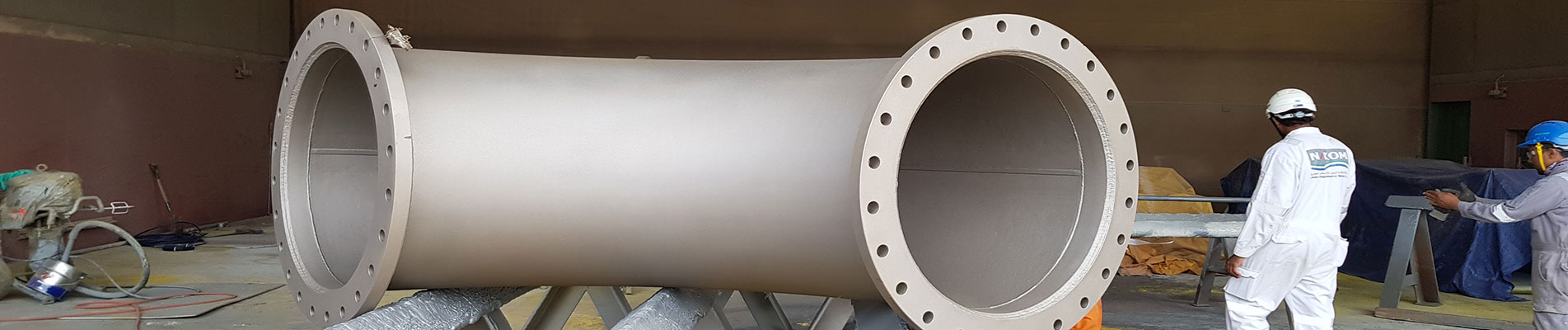

Seawater inlet coating - MetaLine 785 as heavy, elastic erosion and corrosion protection on this seawater inlet. A coating thickness of 3 mm (120 mils) also protects the weld seams in particular. You should not make any technical compromises at this dangerous location!