Propeller coating - the last resort when all other design measures fail in the event of strong cavitation. Propeller coatings are the exception because they slightly change the geometry and also have an impact on efficiency!

Kort nozzle coating – a convincing solution for problem areas exposed to impact and cavitation. Conventional brittle epoxy ceramic products are inadequate in terms of both vibration and wear. The elastomeric MetaLine technology offers completely new solutions to these problems . . .

Sewage pump coating - MetaLine 785 is at home as an OEM protective coating for sewage pumps on most cruise ships . . .

Cooling water pump coating - MetaLine 785 with a coating thickness of 2 mm (80 mils) reliably protects these bronze cooling water pump impellers against decay. Can your crew do this themselves on board? A clear NO - you need coating experts for such complex geometries

Scrubber protective coating - MetaLine 785 in 3 mm (120 mils) thickness as a wear-resistant and chemical-resistant lining on this component of an exhaust gas cleaning system for flue gas desulphurization

Rubber coating corrosion protection - an excellent protection system unfortunately also requires excellent processing and the knowledge of where a coating must begin and where it must end. Here is a prime example of a seamless encapsulation that can no longer be infiltrated

Anti-corrosion coating - the salt water resistance of MetaLine Series 700 - even at elevated water temperatures or high foreign body content - is excellent. Why? Because it is a multi-stage thick protection system and not just thin paint . . .

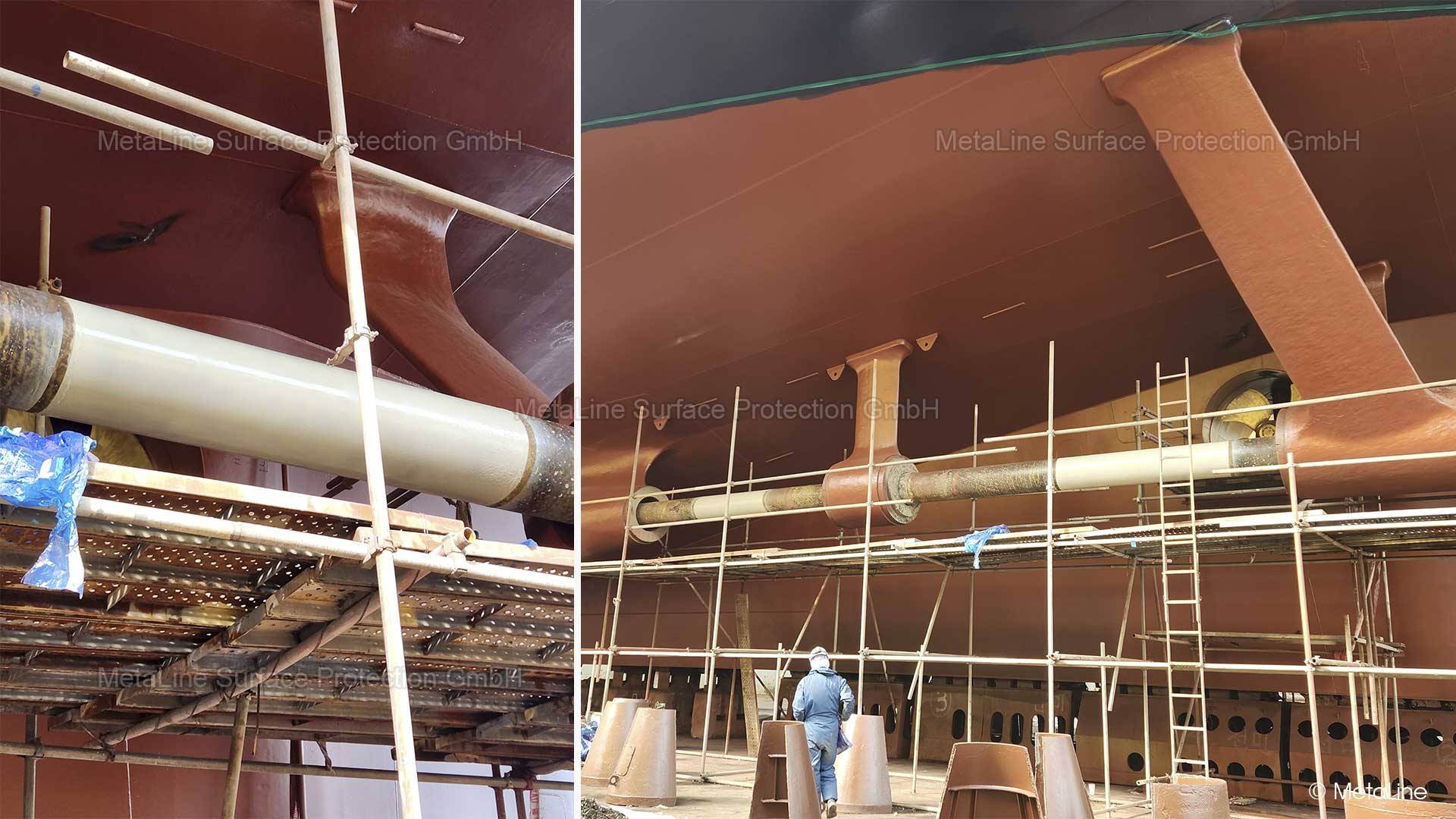

Propulsion coating - the extremely smooth coating with 2.5 mm (100 mils) MetaLine 785 protects this 3 meter (10 feet) large part of a ship's propulsion system of an English frigate from erosion and cavitation. Of course sprayed - and not brushed or filled like our competition . . .

Thruster coating - flow, impact, corrosion and therefore a case for the rubber-like MetaLine 785. Also in use on submarines up to a maximum diving depth of 700 meters (2,300 ft). Plus a signature-altering effect to make localization by sonar more difficult!

Ballast water pipe coating - treatment with 2.5 mm (100 mils) MetaLine 785 effectively creates a second pipe-in-pipe lining. Beginning with the outer flange surfaces and extending over the entire inner surface, a self-supporting rubber hose, so to speak. More protection is not technically possible . . .

Fender repair - a safe application for the MetaLine 785 elastomer armoring and the various MetaLine adhesion promoters. Unfortunately a disaster if you trust the wrong product or insufficient know-how as shown in the picture!

Weight coating – this 3,5 tons fishersnet weight to catch tuna has received an overall coating with 10 mm MetaLine 785 in order to protect the ship hull when entering the net

Saltwater protective coating - so that the harsh offshore conditions no longer give corrosion and decay a chance. MetaLIne is a reliable partner when it comes to preserving substance and safeguarding industrial assets

Propeller shaft coating - every supplier will tell you that their system is the best on the market. Physically, however, there are only 2 basic possibilities: Energy absorption by rubber-like systems or energy deflection by semi-hard plastic coatings. We use the same material that is used in the shaft bearing bushes themselves! Doesn't that sound more logical?