Hard, harder, hardest – this most exactly describes the load parameters of modern marine propulsion systems.

Corrosion would still be the smallest problem, but there is also the impact of solids causing erosion as well as cavitation due to the high speed water flow. A mixture that usually knocks out known surface protection systems quite quickly.

MetaLine takes a completely different way with its energy-absorbing technology:

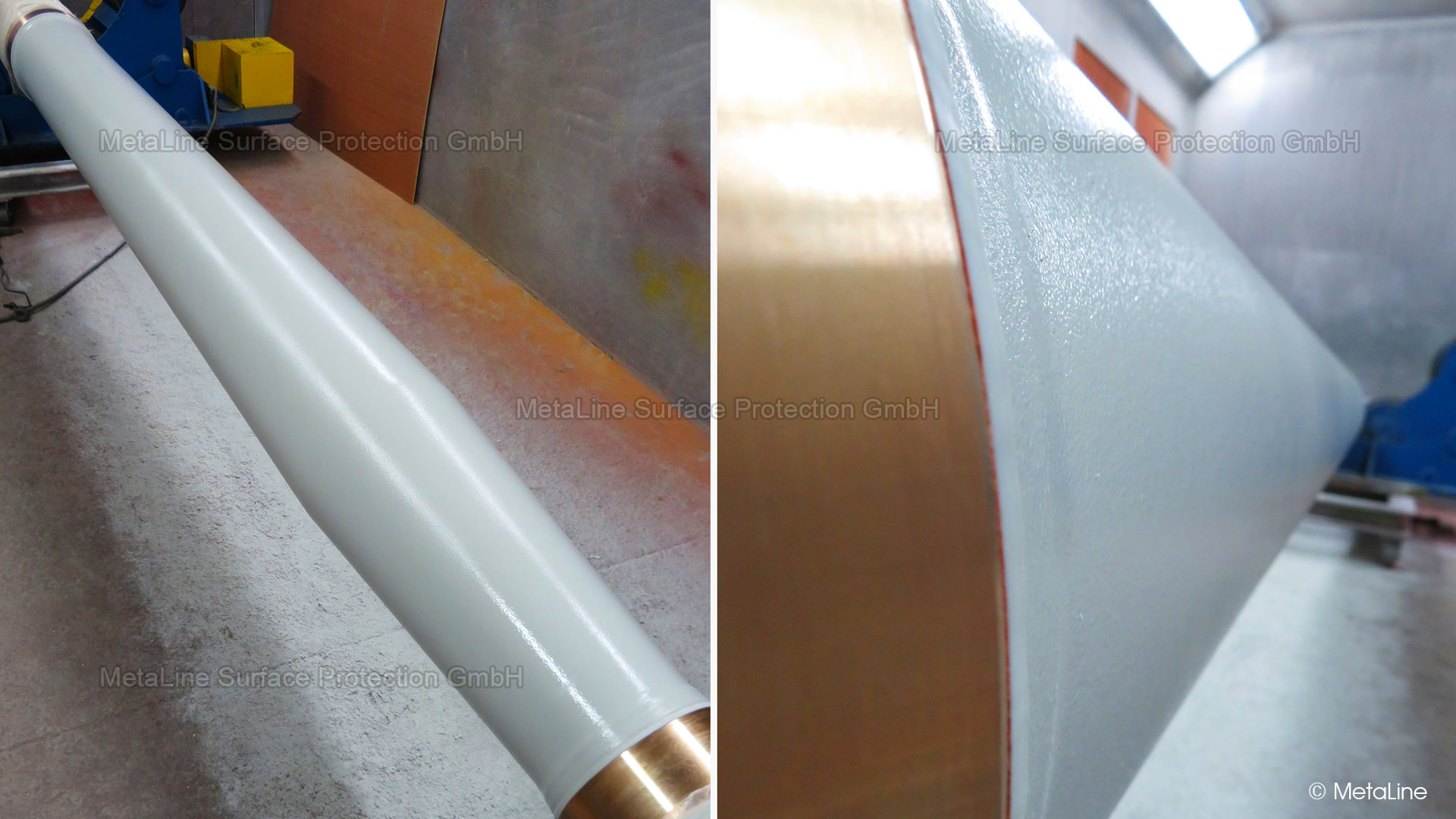

Soft, softer, softest – not paint, not epoxy-ceramic, not rubber, not metallic armoring – but a genious mix of the properties of all 4. This results in a hydrodynamically resistant protective layer with an unmatched erosion & cavitation resistance.

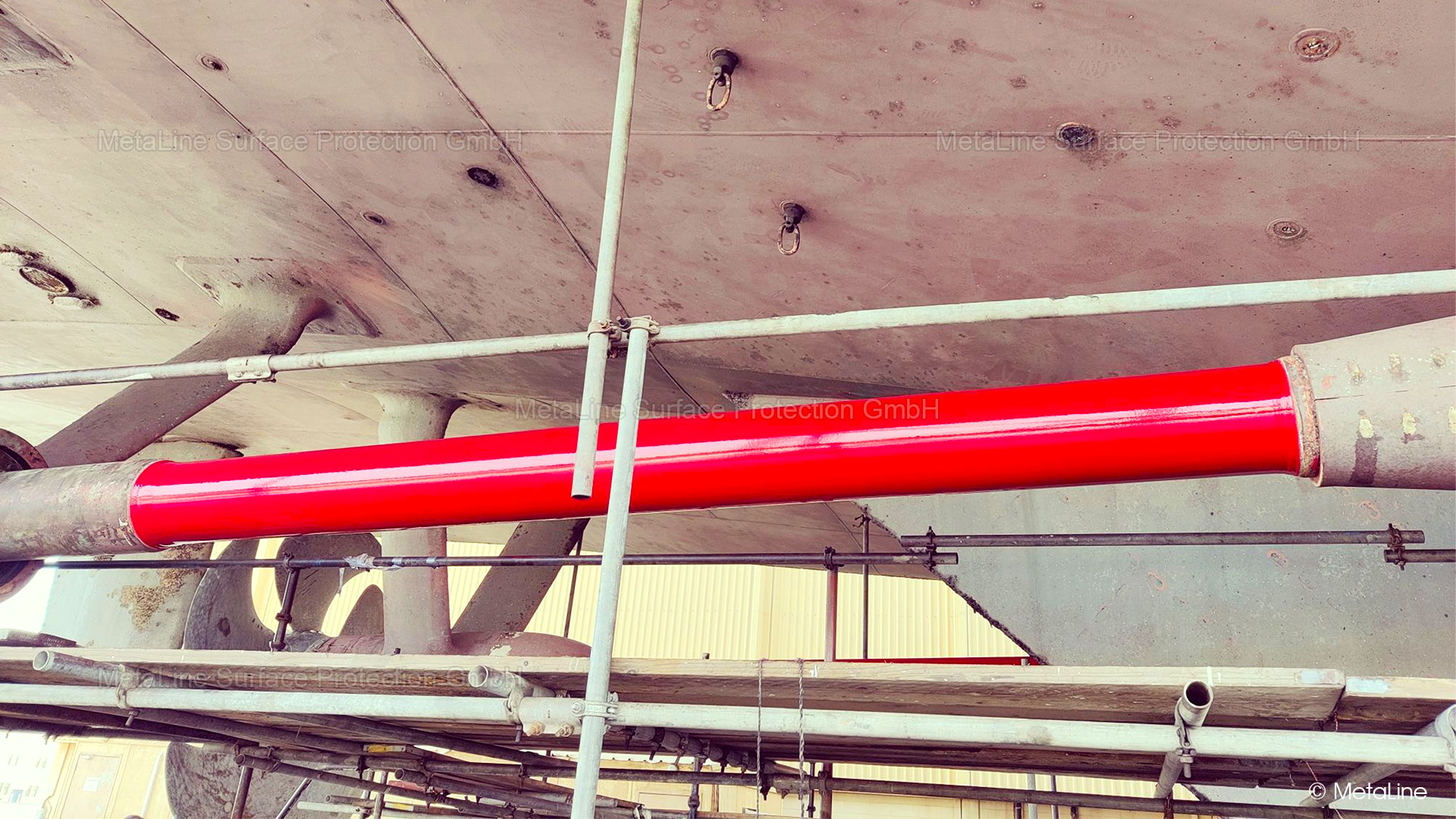

Ask us about: waterjets / jet drives, transition ducts / deflectors, rudderpropellers, kort nozzles, bow thrusters, tunnel thrusters, RIM thrusters, propeller tail shafts, shaft struts (V-brackets)